Researchers in Denmark have studied the technical and financial feasibility of biomethanation by way of large-scale PV energy technology. They mentioned that the intermittent PV-driven biomethanation course of matches the effectivity of steady processes after a number of days.

Scientists from Denmark’s Aarhus College have demonstrated the potential for producing biomethane by way of photovoltaics. They thought-about the way to implement the biomethanation course of in PV-driven operations, the place exercise is shut off because of the lack of photo voltaic radiation.

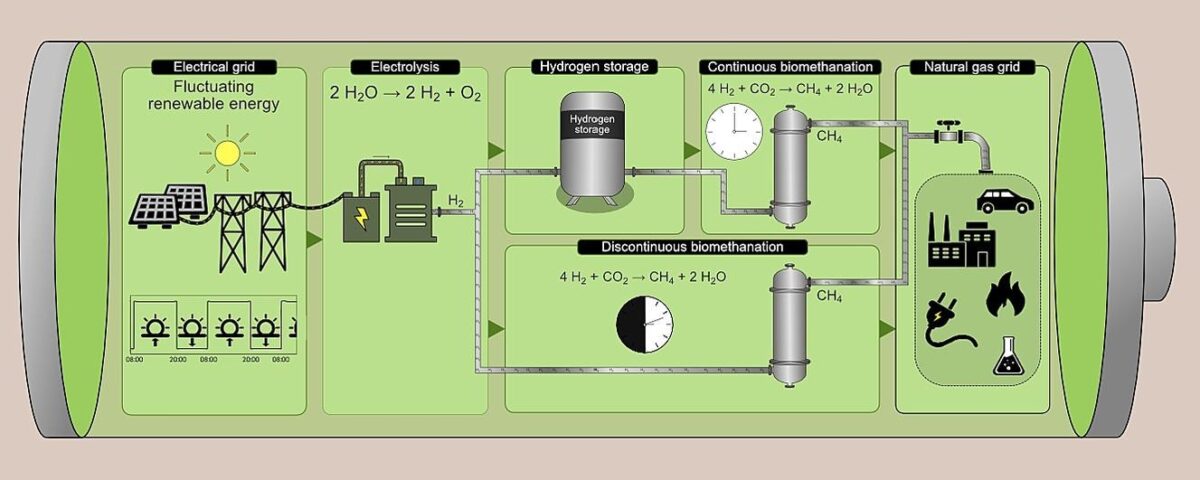

Biomethanation is the processing of natural supplies into biogas, primarily composed of methane (CH4) and carbon dioxide (CO2). On this course of, hydrogen fuel (H2) performs a big position as a substrate for microbial reactions and part of the ultimate product.

“As a substitute for battery vitality storage, the utilization of photo voltaic PV vitality to provide H2 by the water electrolysis course of has been proposed,” the scientists defined. “H2 could also be used as a constructing block to provide different fuels and chemical compounds, [such as biomethane]. Biomethane, with typical concentrations above 98 vol% CH4, is effectively fitted to injection into pure fuel grids.”

To reveal the feasibility of manufacturing biomethane in discontinuous PV phrases, the lecturers first gathered photo voltaic knowledge from the California Flats Photo voltaic Park – a 280 MW PV plant situated in Monterrey County, California.

“On the graduation of the PV-driven discontinuous working mode, it grew to become evident that the TBR didn’t obtain the identical biomethanation conversion effectivity because the prior steady mode of operation,” the lecturers defined. “Nonetheless, after six days of following this discontinuous working technique, the reactor recovered to its baseline efficiency on day 7.”

Picture: Aarhus College, Vitality Conversion and Administration, Inventive Commons License CC BY 4.0

In keeping with lecturers, within the first 4 days of the discontinuous operation, H2 concentrations ranged from 10% to 40% within the biomethane product fuel. Nonetheless, by the sixth day, H2 content material throughout the biomethane was lower than 2%, as desired. Moreover, on days seven to 12, this high quality was achieved inside 16 minutes after start-up; on days 13 to 21, it was achieved instantaneously; and on the final days, it was accomplished inside 20 minutes from operation begin.

“Through the 12-hour standby durations, amassed acids from the operation interval degraded 58.44 % to biogas,” the scientists additional defined. “Thus, the standby durations might synergistically be exploited as a clean-in-place method to take away amassed acids and biomass.”

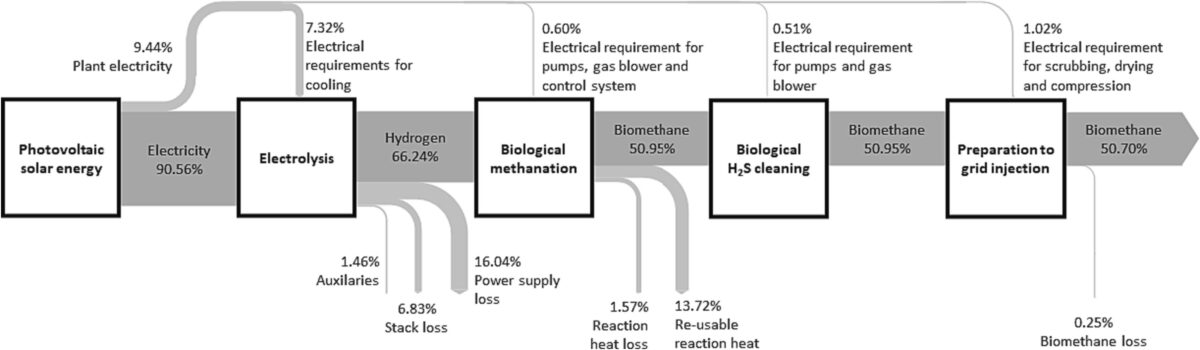

Proving that the discontinuous course of is possible, the scientists suggest a techno-economical analysis. They calculated the PV-driven biomethanation plant to make use of a median of 28 MWh of photo voltaic PV vitality day by day. The electrical energy load for the method was calculated at 2,675.59 kW, and a pair of,423.07 kW of it (or 90.56%) is used for H2 manufacturing by way of electrolysis.

“If a pre-commercial TBR biomethanation plant is deployed at an present biogas facility, the biomethane levelized value of biomethane manufacturing (LCOP) in a 2030 situation is $147.84, with electrolysis as essentially the most important value contributor,” they concluded. “Though this LCOP is increased than standard biogas upgrading, biomethanation gives the potential for CO2 seize and utilization.”

They introduced the novel system configuration in “Sunshine-to-fuel: Demonstration of coupled photovoltaic-driven biomethanation operation, course of, and techno-economical analysis,” which was not too long ago printed in Vitality Conversion and Administration.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and want to reuse a few of our content material, please contact: editors@pv-magazine.com.