Third-party assessments of GDI’s 100% silicon anodes present that they provide greater than 30% vitality density than graphite anodes, permitting for 15-minute speedy charging as much as 80% state of cost (SOC) for a whole lot of occasions again to again.

Lately, the search for next-generation, high-energy-density lithium-ion batteries led to anodes with extra silicon instead of generally used graphite. That’s because of the plentiful, non-toxic materials’s theoretical capability of three,600 mAh/g, in comparison with graphite’s most of 372 mAh/g.

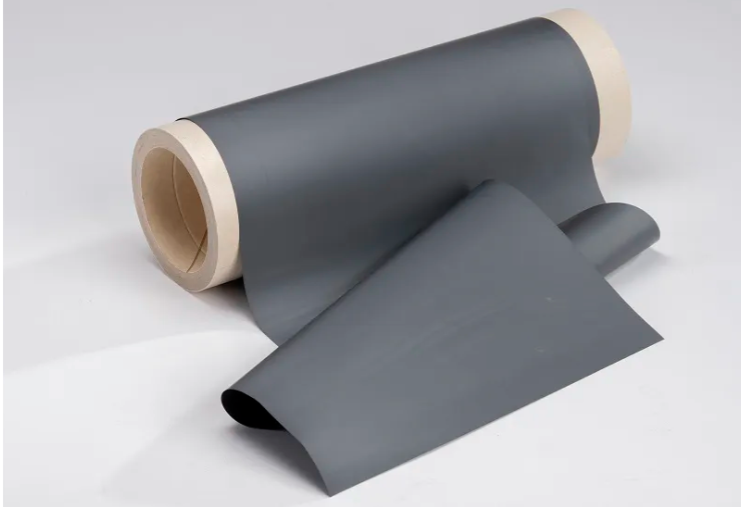

The most recent firm to report vital progress in silicon anode growth is US-based GDI. The corporate has launched a 100% silicon, “roll-to-roll” processed anode and has introduced third-party security testing outcomes.

In keeping with GDI, its silicon anode has proven over 3,200 mAh/g in third-party testing, which permits for greater than 30% vitality density than graphite anodes, enabling repeated 15-minute quick charging for a whole lot of occasions, again to again.

Whereas the perks of quick charging, security and excessive vitality are tough to get concurrently in in the present day’s lithium-ion batteries, GDI says that its know-how permits for all three on account of its silicon structure, bonded on to copper alloy foil made by Germany-based Carl Schlenk AG.

“The subsequent step is to point out our anode can allow EV batteries that energy automobiles with greater than 500 miles of vary, permits them to cost 250 miles in quarter-hour, a whole lot of occasions, and improves security,” stated GDI CEO Rob Anstey. “Our mission at GDI is to ship a whole 100% silicon anode that may be built-in into current battery manufacturing, drastically reduces GHG emissions from the anode manufacturing, and scales quickly on cutting-edge industrial gear.”

GDI has labored in partnership with AGC, a Japan-based glass and plasma coating know-how specialist, to show the MWh scale of its roll-to-roll manufacturing utilizing AGC’s modified glass coating gear. The anode specialist has proven that its completed product might be dropped immediately into current cell manufacturing strains, avoiding quite a few steps and slicing prices.

“GDI and AGC have developed a transparent roadmap to gigawatt-scale manufacturing by 2028, in order that this know-how can utilized in tens of 1000’s of high-performance automobiles by 2030,” Anstey stated.

GDI calculates that its superior manufacturing methodology reduces greenhouse gasoline emissions by 80% in comparison with graphite anodes.

The corporate has additionally introduced third-party testing outcomes displaying that battery cells that includes GDI’s silicon anode are “way more proof against thermal runaway than the present cutting-edge excessive vitality EV cells available on the market.”

The three.5Ah pouch cells had been made by US-based Navitas with an vitality density of greater than 250Wh/kg and that includes an ordinary liquid electrolyte. After leaving a nail pierced by way of Navita’s cell with a GDI anode for 10 hours, there was no fireplace, no smoke, and temperatures solely elevated by 10 C.

Furthermore, the cell was in a position to cross nail penetration testing, even with business off-the-shelf liquid electrolytes, and a excessive nickel cathode, solely heating as much as 30 C, stated the corporate.

GDI is predicated in New York, with a European R&D heart and pilot manufacturing facility in Eindhoven, the Netherlands. It’s at the moment establishing its first MWh-scale roll-to-roll manufacturing facility in Lauenförde, Germany. The corporate is backed by enterprise capitalists, trade specialists, authorities our bodies, EIT InnoEnergy, and strategic buyers.

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.