The New York Energy Authority (NYPA) is main the best way in New York by piloting new applied sciences that may assist speed up the state’s clear power transition. Amongst its accomplishments is a hydrogen demonstration venture at its Brentwood website on Lengthy Island, which was acknowledged with a POWER Prime Plant Award.

It appears nearly all over the place an individual turns today, somebody is speaking about hydrogen. In August, POWER and its sister publication, Chemical Engineering, hosted the HydrogeNext occasion, which is designed to assist the ability and chemical course of industries perceive the total hydrogen worth chain, from manufacturing to distribution and finish use. The occasion—a part of Expertise POWER Week and co-located with Electrical Energy Insights and the Distributed Power Convention—introduced professionals collectively to collaborate and be taught concerning the fast-paced advances being made towards a hydrogen economic system.

Amongst attendees on the occasion in Savannah, Georgia, had been representatives from the New York Energy Authority (NYPA), the Electrical Energy Analysis Institute (EPRI), and GE Vernova’s Gasoline Energy enterprise. The teams had been there to simply accept a 2023 POWER Prime Plant Award for a inexperienced hydrogen demonstration venture accomplished at NYPA’s Brentwood Energy Station on Lengthy Island in Suffolk County, New York.

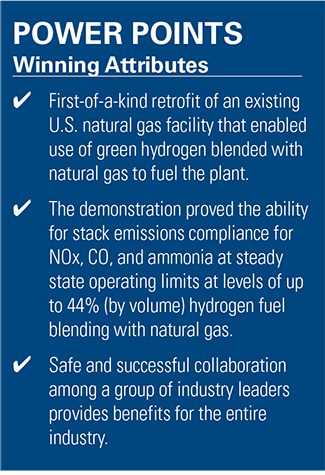

NYPA led the first-of-its-kind venture in collaboration with GE Vernova, EPRI, Sargent & Lundy, Recent Meadow Energy, and Airgas, an Air Liquide firm. NYPA stated the venture was the primary retrofit of an current U.S. pure fuel facility to function on a mix of inexperienced hydrogen to energy the plant and generate electrical energy. NYPA and its trade collaborators demonstrated that the plant was absolutely operational whereas safely utilizing the hydrogen mix. It stated the venture “informs New York and the ability trade by demonstrating that hydrogen could also be one beneficial device to assist decarbonize energy era.”

A Appropriate Web site for Testing

The Brentwood website has a GE LM6000 PC fuel turbine, which was commissioned in 2001 and makes use of a single annular combustor (SAC) combustion system. Over the previous 20+ years, GE has made incremental reliability and efficiency enhancements to the LM6000, and the corporate continues to promote this engine configuration for brand new unit installations in the present day. All take a look at outcomes from the NYPA demonstration are additionally relevant to new LM6000 fuel generators with related combustion configurations (Determine 1).

|

|

1. With greater than 1,300 items shipped and greater than 40 million working hours, GE Vernova’s LM6000 aeroderivative fuel turbine is a well-proven machine. It’s reported to have better than 99% begin and operational reliability, and better than 98% availability. Its five-minute fast-start functionality and excessive cyclic life make it an amazing resolution for complementing renewables or offering peak energy. Courtesy: GE Vernova |

The trouble to review renewable hydrogen on this utility was a part of New York’s complete decarbonization technique as outlined within the state’s nation-leading Local weather Management and Neighborhood Safety Act. “The Energy Authority is main the best way in New York by piloting new applied sciences that may assist speed up New York state’s clear power transition and inform the ability trade in order that we will transfer towards a carbon-free economic system,” NYPA President and CEO Justin E. Driscoll stated in an announcement when the outcomes had been introduced. “Decarbonizing the ability sector would require a collaborative, multi-pronged method, together with using new applied sciences and extra renewable energy sources. NYPA is happy to share the outcomes of our hydrogen examine with the trade and the general public in order that our key learnings might help illuminate future decarbonization efforts.”

The Brentwood website was chosen by NYPA as a result of it’s a single-unit website in a comparatively distant location. The plant’s location and structure, mixed with its comparatively low capability issue as a peaking unit, facilitated the non permanent modifications required for the demonstration venture. Along with having the expertise of curiosity for testing, the Brentwood plant additionally had the area and logistic assist wanted for hydrogen supply and storage whereas testing.

The Gasoline Mix and Outcomes

The gas mixing ranged from 5% to 44% (by quantity) hydrogen. The mix vary was based mostly on a suggestion by GE and was chosen based mostly on a number of elements, together with the aptitude of the engine on the website, the quantity of hydrogen out there, and website situations.

With elevated hydrogen blends, fuel turbine NOx emissions for diffusion-style combustors, equivalent to these on the Brentwood website, could also be greater in comparison with pure fuel as a result of hydrogen’s adiabatic flame temperature is greater. Nevertheless, using abatement applied sciences together with water injection and using post-combustion after-treatment, equivalent to selective catalytic discount (SCR), had been capable of scale back plant NOx emissions.

The NOx emissions restrict on the Brentwood website is 2.5 components per million (ppm) on the stack. NYPA was capable of get emissions allow exceptions for the aim of the demonstration. Nonetheless, the staff was capable of preserve emissions inside present allow ranges in the course of the testing due to the LM6000’s SAC water injected combustor and SCR system.

The short- and long-range impacts of upper hydrogen blends on the engine are a subject of present analysis. Outcomes to this point have been optimistic displaying little sturdiness and upkeep impacts based mostly on laboratory evaluation and short-term discipline testing. Whereas the demonstration didn’t consider the results of hydrogen on the engine and engine bundle parts and supplies, GE Vernova felt snug working the LM6000 on hydrogen blends based mostly on the intensive fleet expertise of its present portfolio of aeroderivative and heavy-duty fuel generators working on fuels with hydrogen content material above 50% (by quantity) and, in a single case, with fuels that include as much as 94% (by quantity) hydrogen. For future exams utilizing greater hydrogen blends, websites might have to improve SCR programs and/or water injection programs to permit for greater water flows as a way to preserve stack emissions just like these obtained when firing on pure fuel.

Total, the fuel turbine output, warmth price, NOx emissions, and CO2 discount had been in step with GE Vernova’s expectations. At 47 MW gross, CO2 mass emission charges had been diminished by roughly 14% at 35% hydrogen cofiring, following the anticipated curve. With fastened water injection charges, NOx ranges elevated by 24% and CO ranges decreased because the hydrogen gas mix was elevated, nevertheless, the NO2/NOx fraction decreased. Further water injection was confirmed to keep up NOx emissions whereas sustaining and even lowering CO. This can be a optimistic profit within the affect on the effectivity and efficiency of some SCR catalyst formulations.

The demonstration proved the flexibility for stack emissions compliance for NOx, CO, and ammonia at regular state working limits on the highest ranges of hydrogen gas mixing (44% by quantity). The discount in CO emissions was about 85% versus pure fuel, which was higher than anticipated.

Gasoline and Security Challenges

From GE Vernova’s perspective, hydrogen availability and supply had been the biggest challenges, as the quantity of hydrogen required for the testing ended up being greater than anticipated. For the demostration, about 1.3 million normal cubic ft of inexperienced hydrogen was used. If condensed to a liquid, that might be equal to about 11,680 gallons. It took the staff loads of planning and glorious on-site execution to align hydrogen availability with continuity of exams, sources, and knowledge assortment.

“The great quantity of hydrogen required was a problem. This was overcome by spreading the take a look at over an extended time period so the hydrogen vehicles could possibly be replenished. As well as, the take a look at was taking us into the unknown. There was no earlier demonstration to check with,” Alan Ettlinger, NYPA’s senior director of Analysis, Expertise Improvement, and Innovation, informed POWER.

“With a number of key collaborating firms on this venture, it was necessary to align on our approaches and overcome any integration challenges in the course of the early planning course of,” an EPRI knowledgeable who labored on the venture stated.

Working on hydrogen all the time comes with potential security considerations. Nevertheless, GE Vernova stated design and plant-level hazardous evaluation critiques recognized all security considerations, which had been then addressed by means of tools upgrades, re-calibrations, personnel coaching, and up to date environmental, well being, and security (EHS) practices.

NYPA stated the venture adopted New York state’s constructing and power code, and all Nationwide Hearth Safety Affiliation (NFPA) necessities. Program managers additionally stored in shut contact with the New York State Division of Environmental Conservation and native emergency companies. “Each morning on testing days, all personnel had been gathered to offer a security transient and the Plan of the Day to make sure all personnel had been briefed on the day’s occasions and protocols to observe,” stated Tim Zandes, senior advisor of Asset Technique with NYPA.

“The massive variety of groups concerned had been capable of produce a design method to make sure that all the protection and operational necessities had been met,” EPRI’s knowledgeable added.

Duties, Findings, and Subsequent Steps

In regards to the staff and every group’s tasks, NYPA led the venture, as beforehand famous. GE Vernova assisted within the constructing of the state-of-the artwork hydrogen/pure fuel mixing system. EPRI’s Low-Carbon Assets Initiative helped design the venture and served as advisors on the technical analysis. Airgas equipped the renewable inexperienced hydrogen for the testing. Sargent & Lundy was the unique architect engineer of the Brentwood plant and supplied engineering experience in addition to security critiques. And final, however not least, Recent Meadow Energy developed the piping system that delivered the hydrogen to the GE-designed mixing skid and, in the end, into the turbine.

In accordance with NYPA, this cutting-edge analysis gives vital insights into the potential for mixing clear hydrogen and pure fuel, which is one potential use amongst many for clear hydrogen. This knowledge gives extra data to assist continued discussions about the way forward for clear hydrogen that may leverage New York’s dedication to reaching a zero-emissions electrical grid and the world’s distinctive geographies and considerable renewable sources.

GE Vernova is constant to conduct testing in its combustion laboratory to broaden the aptitude of SAC combustion programs with a objective of permitting emissions-compliant fuel turbine operation on 100% hydrogen within the close to time period. As well as, GE Vernova can also be creating next-generation DLE (dry low emissions) combustion expertise to function on 100% hydrogen with out the necessity of water injection for NOx management.

—Aaron Larson is POWER’s government editor.