Westinghouse has revealed it’s designing a transportable nuclear energy plant (TNPP) that includes an eVinci microreactor with Canadian agency Prodigy Clear Power, aiming to ship a primary challenge in Canada by 2030.

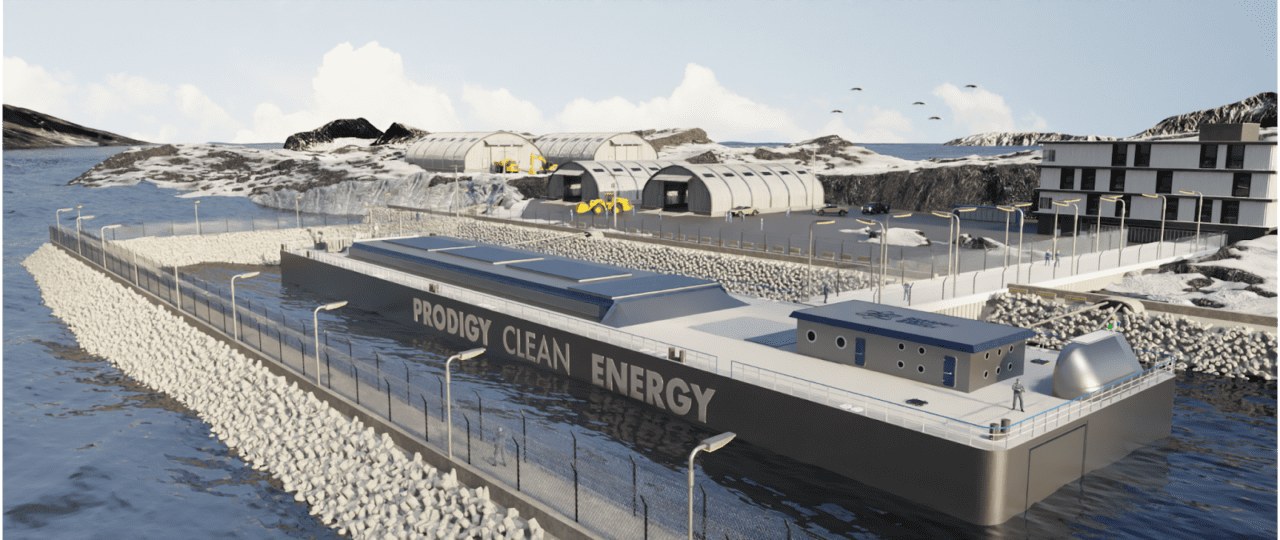

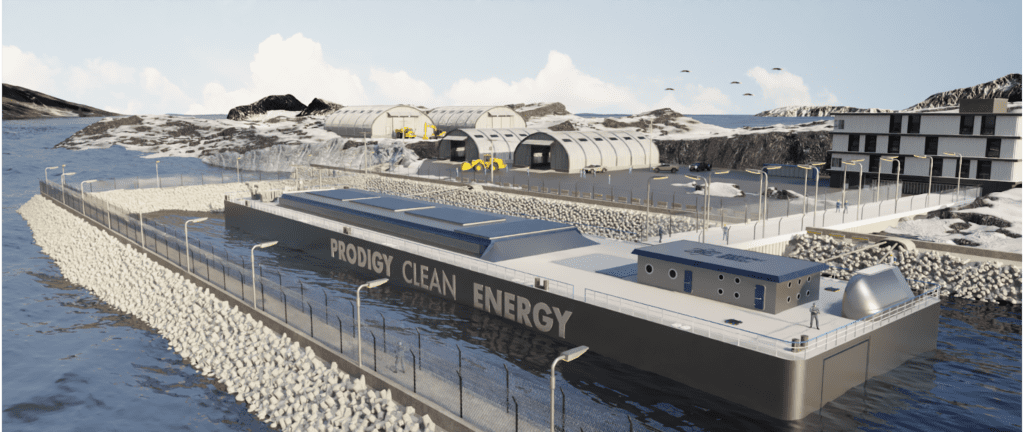

The challenge will probably combine a single or a number of 5-MWe eVinci microreactors inside a Prodigy Microreactor Energy Station—a purpose-designed floating facility that may possible be deployed at a shoreline. The TNPP could be pre-fabricated and transported to web site to provide dependable energy and warmth to “distant industrial websites, information facilities, communities, protection installations, and to islands and island nations,” Westinghouse mentioned in a weblog put up on Jan. 23.

Whereas the goal location in Canada is topic to a non-disclosure settlement, Prodigy informed POWER the corporate is at present “working with end-users within the mining business in Canada to conduct web site feasibility assessments for potential deployment of a TNPP that includes the eVinci microreactor.”

A Novel Method to Allow Nuclear Fleet Deployment

The TNPP challenge will mark Prodigy’s entry into the worldwide floating nuclear energy plant (FNPP) market, which has flourished lately, propelled by a worldwide urgency so as to add new nuclear capability to deal with trendy energy challenges.

Whereas FNPPs—primarily naval amenities and nuclear icebreakers—have operated because the mid-Nineteen Sixties, business observers level to new potential roles for the area of interest market, together with to supply dependable energy and warmth to distant and off-grid areas, to bolster renewables-heavy grids, and to furnish power-intensive industries with new clear power choices. The prospect of dependable cellular energy and warmth might open up new purposes for offshore oil and fuel platforms, business ports, mining and deep-sea mining, hydrogen and artificial gasoline manufacturing, aquafarming, ocean cleanup, desalination, and information facilities, they recommend.

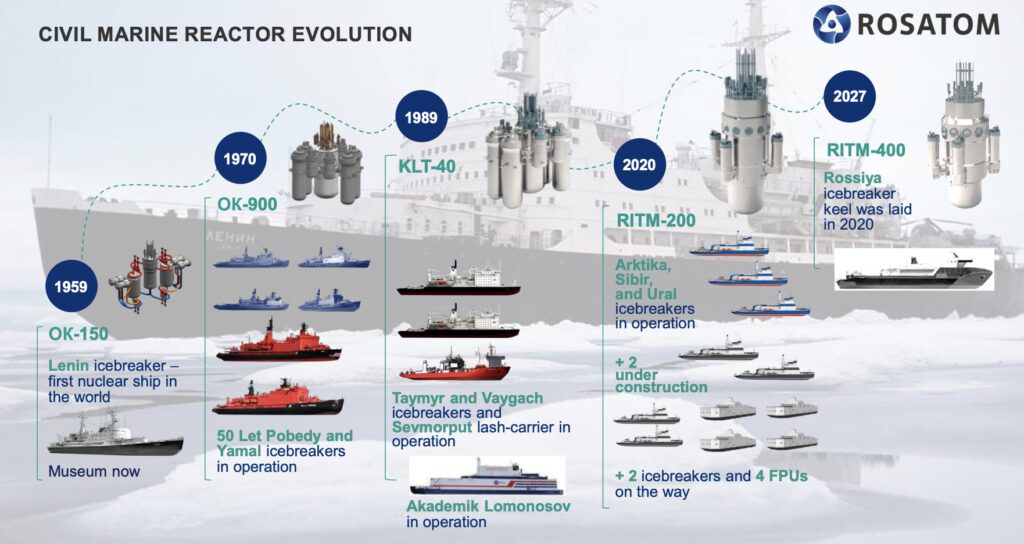

Thus far, just one purpose-built FNPP is operational: the 70-MWe/58-MWth Akademik Lomonosov, in Pevek, Chukotka, in Russia’s Far East, which Russia’s state-owned nuclear firm Rosatom formally started working in Might 2020. Nonetheless, the Worldwide Atomic Power Company (IAEA) data at the least eight water-cooled marine-based small modular reactors (SMRs) amongst 83 SMR designs beneath improvement and deployment worldwide. Not less than 5 FNPP designs are within the detailed design stage, it notes.

Prodigy underscores flexibility might be a key driver for the rising FNPP market. However moderately than growing reactors, its strategy is to associate with main SMR distributors to supply a standardized, scalable, and totally transportable nuclear energy plant system—basically by linking experience in three mature industries: nuclear, maritime, and transport.

A Transportable Nuclear Possibility

The excellence carried by TNPPs, as Westinghouse famous on Tuesday, is necessary. “The IAEA defines a TNPP as ‘a manufacturing unit manufactured, movable nuclear energy plant… able to producing ultimate power merchandise equivalent to electrical energy and warmth.’” it mentioned. “This contains ‘Floating Nuclear Energy Crops’ which can be docked near the place the power is required, decreasing the necessity for constructing the everlasting infrastructure.”

Underneath Prodigy’s mannequin, the construction could be shipyard-fabricated and, after outfitting, could be transported by a devoted heavy-lift service to its deployment location. “However then the deployment itself would have particular infrastructure in place to carry and home the vessel in a protected place,” as Prodigy Clear Power President and CEO Mathias Trojer defined throughout a November 2023 panel on the IAEA’s first symposium on FNPPs.

“FNPPs isn’t just about reactor possession, it’s an built-in facility whose programs—nuclear in addition to non-nuclear—should work collectively to exhibit that nuclear, marine, maritime transport and environmental rules are being met, and that nuclear supplies might be appropriately safeguarded,” he famous.

“We’re merging confirmed applied sciences in nuclear engineering and nuclear civil building with many years of expertise in marine manufacturing, [operations and maintenance (O&M), lifecycle management of vessels, and integrating these with well-established approaches to nuclear and heavy equipment transport,” he said. “By selecting SMRs with proven safety and operability features at an adequate level of technology readiness, and capitalizing on best practices across these three industries, Prodigy will deliver FNPPs that are safe, robust, economical, but most importantly, licensable under current frameworks and ready for near-term implementation,” he said.

For now, the company’s focus is centered on developing two active programs to allow SMR developers to package their reactors into TNPPs—the Microreactor Power Station, which can be marine or land-based variants, and the Grid-Scale Station, which would be installed at a shoreline within a protected harbor.

Prodigy, notably, already has a memorandum of understanding with NuScale Power for a grid-scale marine TNPP that could feature six to 12 NuScale modules (for a combined output of 924-MWe). Since the companies completed conceptual design and economic assessments for the potential project in 2021, work has been ongoing “to progress” the design, it told POWER on Tuesday. In November, Prodigy’s Trojer suggested the company was slated to begin a site pre-feasibility assessment with end-users that could factor in the power needs of a “large industrial site.” Prodigy is also continuing to work with Kinectrics, a testing, inspection, certification, and consulting firm, “given their significant expertise, especially in nuclear regulations and nuclear safety analysis,” the company noted.

Its first project, however, will be its Mirocreactor Power Station TNPP featuring a Westinghouse eVinci microreactor. “All practices being developed, including methodologies to licensing, transport, logistics, deployment, and decommissioning, to support Prodigy’s microreactor TNPP program, are directly translational to Prodigy’s grid-scale marine TNPP program,” the company said.

eVinci—A ‘Plug and Play’ Design Well-Suited for TNPPs

As Westinghouse noted on Tuesday, its project with Prodigy stems from a 2019 collaboration that sought to evaluate deployment models for the eVinci microreactor. Westinghouse’s flagship microreactor, introduced in 2017, is a fully passive heat pipe–cooled design that will use tristructural isotropic (TRISO) fuel and alkali metal heat pipe technology. The design, which can provide a reliable source of industrial-grade heat—of up to 600C—features few moving parts, requires no water, and can operate for eight-plus years without refueling. Westinghouse has told POWER the design is well-suited to various applications, including remote mining operations, remote communities, industry, and distributed energy.

The design, notably, already has a potential first customer—Saskatchewan Research Council (SRC), Canada’s second-largest research and technology organization. SRC has said it plans to pilot an eVinci microreactor by 2029, though that timeframe will be subject to licensing and regulatory requirements. Saskatchewan’s provincial government is expected to determine that project’s location as it progresses.

Work toward a potential TNPP design for the eVinci, has also progressed relatively quickly. “A multinational corporation operating strategic critical minerals assets in Canada funded a study in 2019-2020 to identify more reliable clean energy sources,” Westinghouse said on Tuesday. “In the study, Prodigy assessed the eVinci microreactor for deployment in a marine facility fixed at shoreside to power a remote mine.”

In 2022, Westinghouse and Prodigy signed an agreement to further a potential TNPP design customized for eVinci. So far, backed with an award from Canada’s Strategic Innovation Fund, the companies have completed milestones for conceptual engineering and regulatory studies.

“Next steps for Westinghouse and Prodigy include completing the TNPP design for the eVinci microreactor, completing development of a nuclear oversight model for TNPP manufacturing, outfitting and transport, and progressing licensing and site assessments to support a first project in Canada by 2030,” Westinghouse said.

According to Jon Ball, president of eVinci Technologies at Westinghouse, the TNPP from Prodigy “brings an additional value to the inherent transportability of the technology.” From the start, “our eVinci technology was designed to be transportable, that was a key design principle,” he noted.

Prodigy’s Trojer, meanwhile, noted eVinci’s “compact design and simplified operating requirements make it optimal for integration into a Prodigy TNPP.” The technology “will enable fleet deployment of the eVinci, accelerating the timeline to deliver clean, reliable, and affordable power at commercial scale to remote regions,” he said.

FNPP Companies Are Embarking on Uncharted Waters

While Prodigy’s model could provide a simplified new pathway for reactor vendors to potentially integrate their SMR designs into standardized TNPPs, Trojer has acknowledged that several challenges lie ahead for the widespread deployment of FNPPs.

“Executing the development and deployment of an FNPP is a very complex exercise that needs to be carefully planned and systematically carried out,” he said during the IAEA’s panel in November. While the Akademik Lomonosov “is a highly successful proof of concept,” as the industry sets out to “pioneer a new paradigm, there are significant questions that must be answered around the design, replicability, standardization, the regulations, and more generally, the legal framework,” he said.

Prodigy’s choice of Canada as its first project was “strategic,” he noted, given the country’s “highly mature regulatory framework and regulator.” Canada also offers strong government support for local innovations, he said. “Prodigy’s emergency planning approach is informed by the safety features of the SMR and decides conditions where the facility will be deployed. We’re using the IAEA safety and security framework as a benchmark, and where more precision and detail is required, we look at the Canadian and U.S. nuclear regulatory framework,” said Trojer.

Several companies in the emerging FNPP market, however, are considering broader approaches that support offshore commercial activities such as mining and oil and gas projects, while others are exploring deploying nuclear reactors in commercial cargo ships to decarbonize shipping.

Danish technology firm Seaborg, for example, is developing the Compact Molten Salt Reactor (CMSR) power barge, a 250-MWth/100-MWe molten salt reactor designed for use in modular floating nuclear power barges. According to Seaborg CEO and co-founder Navid Samandari, the modular power barge, which will be serially produced at shipyards, “can be constructed fast and at low cost.” The biggest challenges Seaborg faces, however, relate to licensing, he noted.

“That’s where two worlds need to meet,” Samandari noted during the November IAEA symposium panel. “Currently, there is no regulatory framework for molten salt reactors, and there is no regulatory framework for floating nuclear facilities. That’s why the regulatory pre-engagement is key, and where we are now is the first step in this dialogue on a potential licensing.” The two worlds that will significantly “need to meet” include the International Maritime Organization (IMO), which maintains a regulatory framework for international shipping, and national regulatory bodies, he said.

At the November IAEA event, Andrey Rozhdestvin, general director of JSC Rusatom Energy Projects, highlighted Russia’s progress on FNPPs after its rollout of the Akademik Lomonosov—a project that spanned more than 15 years from construction start to completion. The pioneering FNPP recently completed its first 3-year refueling of its KLT-40S reactors, which have a cartridge-type core.

Russia has since adopted the RITM-200M, derived from the latest Russian icebreaker projects, for its fleet of Optimized Floating Power Units, which are considered the second generation of marine-based SMRs. So far, six RITM-200 reactors, built as a series of icebreakers, have already been successfully installed in Russia’s Arctic, Siberian, and Ural regions, manufactured under a unique “conveyor belt” model by Rosatom’s Mechanical Engineering Division in Podolsk. However, a contract for the supply of the power units has ended.

According to the IAEA, another design, the ABV-6E, “although in its finished final design, it has not yet been licensed. The VBER-300, a unique design completely relying on passive safety systems, is in the stage of completing its basic design documentation.” Russia, notably, is also working on a water-cooled RITM-200N that adapts adapts a shipboard design for a ground-based SMR and a project Yakutia is expected to begin operations in 2028.

However, Rozhdestvin also underscored a list of challenges the FNPP sector must consider. These include “mobility,” along with safety improvements, and cost reductions. Another issue hovers around shipbuilding capacity. “We are facing the lack of capacities. We have preliminary interest in 50 nuclear plants, and even if we can internally produce our reactors to fulfill market demand, if we talk about shipyards, we have to go not only in Russia but abroad,” he said. “It means if you are talking to shipyards and you want to scale up, you need to explain the program based on serial production, and [this poses] uncertainty relating to [nuclear and maritime] rules and necessities in every nation, in addition to worldwide necessities.”

Mikal Bøe CEO and founding father of Core Energy, a UK firm that’s growing nuclear ships and dealing to turn out to be a “a licensed, type-approved superior nuclear-electric energy package deal for ocean transportation and heavy business,” additionally instructed mobility will all the time be a key problem.” He mentioned the sector might want to guarantee “varied strands are tied collectively to try this.” Core Energy, notably, is working with TerraPower, Southern Co., and the U.S. Division of Power on the Molten Chloride Quick Reactor (MCFR), that “will go reside in 2026” and inform a ultimate design for a bigger machine. “They’ll go into the FNPPs that we intention to launch,” he mentioned.

Challenges related to rolling out a first-of-a-kind FNPP are associated to security, Bøe instructed.“It’s actually a distinct strategy to security,” he mentioned. “If we’re going to have seafarers and nonnuclear technicians function on the nuclear energy aspect like this, we’re going to must have a passive walkaway security system. A lot of the reactors, actually Gen III+ to Gen IV reactors, are the signal for passive security, in order that’s not a tough hurdle to climb, we expect,” he mentioned. “Importantly, I feel a kind of is a low-pressure system or an ambient strain system, and the explanation for that’s associated to the emergency planning zone.”

Waste administration may also emerge as a problem, Bøe predicted. “The dealing with of waste the dealing with of spent nuclear fuels and radioisotopes imports is all the time going to be a contentious difficulty. If we are able to keep away from this by having very lengthy gasoline cycles in closed-cycle reactor expertise, we are able to begin to overcome them,” he mentioned.

Trojer famous that Prodigy, too, thought of the potential for business nuclear propulsion in ocean-going and internationally crusing vessels as a part of a two-year delivery business–funded challenge that resulted in 2020. Whereas the research decided that microreactors “had been technically possible,” the regulatory and authorized frameworks wanted to help near-term commercialization of nuclear delivery, “or extra merely, deploying an working reactor onboard self-propelled civilian vessels don’t at present exist,” he informed POWER. “It turned clear to Prodigy that the fast path to market could be non-self-propelled, shoreside-installed marine microreactor amenities.”

For now, Prodigy continues engagement with the IAEA, however additionally it is actively working with the U.S. Nationwide Reactor Innovation Middle (NRIC) Marine Nuclear Utility Group (MNAG). “In every case, representatives from the nuclear and marine sectors are laying out approaches to deploy marine TNPPs and to determine and resolve any authorized and regulatory gaps which may impede these applied sciences from being efficiently deployed. For instance, Prodigy is working inside MNAG to publish a report that covers ‘a assessment of the Regulatory and Licensing Panorama’ for marine-based TNPP amenities,” the corporate mentioned.

—Sonal Patel is a POWER senior affiliate editor (@sonalcpatel, @POWERmagazine).