The digital age is upon us and the facility trade is a key participant on this thrilling time. Important work routines and asset administration processes have already been reworked. Energy plant operations are among the many areas the place superior know-how has had a big effect.

Energy plant lifecycles are complicated. Energy corporations spend important money and time evaluating electrical energy market provide and demand tendencies merely to know if new or upgraded property are wanted. Then, decision-makers should overview all of the choices earlier than selecting the kind of era they wish to use to fill gaps. The planning, designing, and executing of tasks can take a few years and infrequently requires many hundreds of thousands and even billions of {dollars} in investments. As soon as development is full and models are commissioned, the property are anticipated to final many years, which requires ongoing investments in operations, upkeep, and safety. Lastly, when property close to their finish of life, choices have to be made on when and methods to perform the decommissioning course of and repurpose websites. It’s actually a tremendous journey from begin to end.

The truth that we reside in a high-tech world at present makes managing energy plant lifecycles each simpler and tougher. When know-how is designed properly, included into crops appropriately, and works correctly, it will possibly present the info and perception wanted to high-quality tune essentially the most difficult operations, bettering effectivity and maximizing revenue. However when issues go improper, it will possibly depart technicians and managers scratching their heads and feeling misplaced troubleshooting gear and parts that they might not totally perceive. Nonetheless, the advantages far outweigh the dangers, and outdoors consultants are at all times out there to assist resolve complicated issues, permitting at present’s superior know-how to assist energy corporations attain broader targets, together with bettering reliability, enhancing sustainability, selling decarbonization, and including enterprise worth.

How Digitalization Has Modified the Energy Business

Power and energy corporations are accelerating their digital transformation to handle new mission ventures, decrease operational danger, cut back downtime, improve effectivity, meet regulatory compliance, and stay aggressive. Progressive software program options can be found at present for the vitality and energy trade that allow clever planning, designing, and executing of tasks, in addition to working, sustaining, and securing of property.

For instance, digital instruments can be found to assist upkeep planners carry out their jobs higher. One modern answer permits planners to know and evaluate prices and hours for corrective, preventive, and condition-based upkeep. This permits groups to carry out the correct sort of upkeep (Determine 1) to maximise productiveness whereas minimizing price. Managers also can acquire and decipher information on overdue work orders to raised perceive the implications of delays and prioritize future actions.

The success of complicated engineering tasks requires a linked digital ecosystem, the place unstructured data is reworked into sensible digital property that improve effectivity and enhance security whereas reducing prices and delivering anticipated enterprise returns. Progressive mission engineers have discovered nice worth in all-encompassing mission execution platforms. Fairly than utilizing a tangled net of in-house-developed instruments, industrial software program, and spreadsheets to handle tasks haphazardly, main organizations have discovered a centralized portfolio and mission administration surroundings more practical. Such a system seamlessly connects information between totally different disciplines, standardizes processes throughout an enterprise, and supplies crystal clear visibility into the efficiency of each mission in actual time.

Sound well being, security, and surroundings (HSE) administration is essential to sustainable energy plant operations. Nevertheless, many energy corporations are nonetheless utilizing paper, spreadsheets, and phrase processor instruments to doc and handle the execution of safety-critical plant processes. Info is commonly scattered in varied folders and databases all through the group, lowering the effectiveness of packages and leaving corporations weak to regulatory scrutiny. Digital options can be found to assist reduce dangers, and allow HSE and course of security groups to scale back incidents and successfully meet inside and exterior compliance necessities.

Ahead-thinking operations managers are utilizing digital instruments to accumulate a priceless, data-driven expertise that encapsulates simply consumable, well timed data concerning previous occasions, current info, and future predictions. These programs can seamlessly join safety-critical operational processes, procedures, and permits; alarm administration methodology; upkeep work orders; real-time and historic course of information; engineering schematics; and technical documentation with laser scanning information, 3D fashions, and cybersecurity safeguards to allow a sturdy and complete digital twin for all the operation.

To deliver all of it collectively and maximize the worth of those new digital capabilities, a system that delivers a unified, role-based view of the bodily and digital realities throughout services is accessible. This built-in view supplies real-time visibility into asset efficiency, security, safety, and high quality to allow better-informed choices that improve productiveness, operational integrity, profitability, and sustainability. It encompasses a digital infrastructure that connects information throughout all the asset lifecycle, enabling managers to realize extra with digital twins, third-party software program, and legacy programs.

Modernizing Legacy Methods

Anybody with a pc or cellular phone is aware of that know-how is consistently evolving. What handed for state-of-the-art a number of years in the past could also be thought-about out of date at present. Whereas there are most likely folks on the earth who nonetheless carry a flip cellphone, anybody with a sensible cellphone may inform them that the brand new know-how is much superior to the previous and the capabilities of every are hardly comparable.

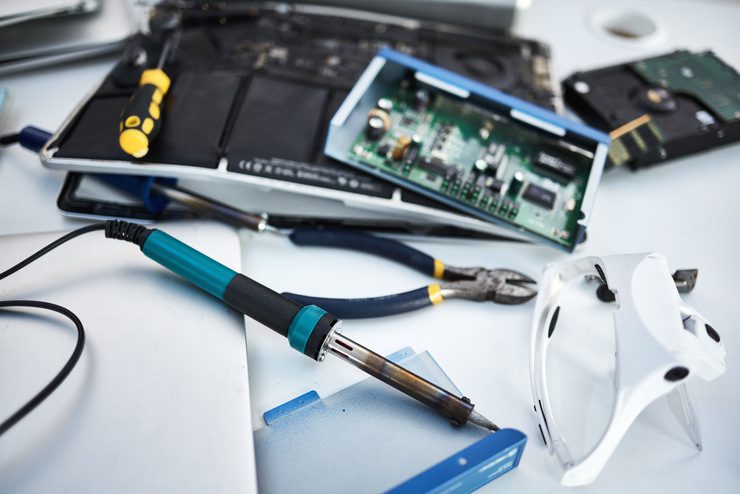

The identical is true of know-how in energy crops. Operational know-how (OT) and industrial management programs (ICSs) present the spine for energy plant operations at present. Each are usually a part of a specialised {hardware} and software program ecosystem utilized in industrial environments (Determine 2), together with energy crops, to observe and management bodily processes.

Whereas OT and ICSs have been in use for many years, quite a bit has modified through the years. New OT programs profit from advances in networking applied sciences, enabling higher connectivity and interoperability between totally different gadgets and programs. Higher connectivity facilitates real-time information change, distant monitoring, and centralized administration, resulting in improved effectivity and decision-making.

Cybersecurity has additionally been improved over time. Conventional OT and ICS programs typically lacked sturdy safety measures, making them weak to cyber threats. New OT incorporates stronger cybersecurity practices, together with safe protocols, authentication mechanisms, encryption, and intrusion detection programs. This helps defend essential infrastructure from cyberattacks and ensures the integrity and availability of OT programs.

New OT additionally leverages ideas developed within the data know-how (IT) area, resembling cloud computing, huge information analytics, synthetic intelligence (AI), and machine studying. With these enhancements to OT programs, organizations can achieve priceless insights, optimize operations, and allow extra superior automation. Fashionable OT architectures are additionally designed to be extra scalable and versatile, facilitating simpler integration of further gadgets, sensors, and parts, which permits corporations to adapt to altering necessities with out main disruptions.

However maybe the most important change in OT and ICS programs at present entails analytics and decision-making enhancements. New OT programs can acquire and course of giant volumes of real-time information from varied sources, enabling superior analytics, which empowers organizations to make data-driven choices, optimize operations, cut back downtime, and improve total efficiency. Upgrading legacy programs because of this alone may pay dividends.

Knowledge, Knowledge, and Extra Knowledge

Energy plant OT programs generate and acquire a big quantity of knowledge from varied sources, resembling sensors, meters, management programs, and monitoring gadgets. The info consists of details about system pressures, temperatures, and flows; gear standing; environmental circumstances; upkeep information; and extra.

The amount of knowledge generated and saved by all the facility crops on the earth is sort of unfathomable (Determine 3). Massive energy crops or these with intensive monitoring programs could have many terabytes of their databases, relying on the plant capability, and frequency and period of knowledge assortment.

But, all this information is vital and crucial to totally capitalize on the advantages of superior analytics. That’s why it’s so vital to get rid of unstructured, duplicated, and disconnected information and documentation, whereas guaranteeing information accuracy, integrity, and reliability. Consolidating digital information sources will cut back storage necessities, whereas nonetheless permitting clever data to be gleaned from databases. Investing in a complete digital transformation technique can speed up an organization’s steady enchancment efforts.

Workforce Challenges

Energy corporations are going through workforce challenges throughout the board. Some research recommend the share of energy trade employees eligible for retirement is as excessive as 40%, however discovering substitute employees is troublesome. For instance, Public Service Enterprise Group Inc. (PSEG), a diversified vitality firm headquartered in Newark, New Jersey, had near 500 energetic job openings in March 2023. Whereas a few of the openings had been on account of a development in capital work, the corporate’s Chief Human Sources Officer reported a turnover price on retirements of about 3% in 2022, which quantities to plenty of jobs in a workforce of about 12,500. Many different energy corporations have reported comparable statistics.

In some circles, particularly amongst youthful generations, the facility trade is perceived to be antiquated and boring, however that’s removed from the reality. As has already been famous, superior know-how and modern programs are on the coronary heart of most energy crops. Moreover, many energy corporations are addressing the workforce scarcity by implementing new know-how that captures and makes use of data from soon-to-be retirees, and reduces the necessity for expert labor.

In the meantime, know-how employees are in excessive demand, not solely within the vitality and energy industries, but additionally in virtually each different sector of the economic system. The U.S. Bureau of Labor Statistics (BLS) predicts total employment in laptop and data know-how occupations will develop 15% from 2021 to 2031, which is way sooner than the typical for all occupations. Moreover, the BLS says the median annual wage for this group was greater than double the median annual wage for all occupations in 2021, which is no less than partly a mirrored image on the demand for these employees. Whereas which will make it onerous to rent in-house employees to implement and preserve OT and ICS tasks, it exhibits the worth of getting a trusted contractor that has the consultants wanted to handle these programs.

Regulatory, Coverage, and Stakeholder Issues

Energy corporations have a eager deal with reliability and for good purpose. Clients don’t respect it when their energy is off. That’s why instruments that enhance reliability are so vital.

There are various digital options out there at present that improve energy plant reliability, and plenty of extra which might be more likely to be out there quickly based mostly on AI and machine studying options. But, many observers fear in regards to the impact AI could have on operations, particularly the way it may influence the workforce and jobs.

Regulators and policy-makers are considering one of the best ways to offer oversight on AI functions. A Harvard Enterprise Evaluate (HBR) article steered that the diploma of belief in AI varies with the sort of choices it’s used for. “When a job is perceived as comparatively mechanical and bounded—assume optimizing a timetable or analyzing pictures—software program is considered no less than as reliable as people,” it mentioned. “However when choices are regarded as subjective or the variables change (as in authorized sentencing, the place offenders’ extenuating circumstances could differ), human judgment is trusted extra, partially due to folks’s capability for empathy.”

Within the OT world, AI will most certainly be used extra for “mechanical and bounded” choices. Nonetheless, the HBR article mentioned extra stringent AI laws “are on the horizon (no less than in Europe and america).” With that in thoughts, corporations will want new processes and instruments, resembling system audits, documentation and information protocols (for traceability), AI monitoring, and variety consciousness coaching to satisfy altering laws. “A lot of corporations already take a look at every new AI algorithm throughout quite a lot of stakeholders to evaluate whether or not its output is aligned with firm values and unlikely to boost regulatory considerations,” the article notes.

Making a Sound Digital Technique

Whereas it’s at all times prudent to look at all choices and selected a plan of action solely after weighing professionals and cons completely, there’s important danger in shifting too slowly down the digital transformation path. Right now’s energy and vitality markets are very aggressive, and it’s straightforward to fall behind within the race to remain related.

To attain their mission of supplying reliable electrical energy to prospects across the clock, energy corporations should plan, design, execute, function, preserve, and safe property in a dependable, sustainable, cost-effective, and accountable means. To maintain stakeholders joyful, they have to full tasks on time and on price range. Digital know-how supplies the instruments crucial to perform these targets.

A sound digital technique is required to successfully information a corporation’s digital transformation and leverage digital applied sciences. Among the many first gadgets corporations should deal with is creating a transparent imaginative and prescient with particular targets and desired outcomes. The digital technique ought to articulate how digital applied sciences will assist the group’s total targets.

An organization’s digital technique should additionally align with its broader enterprise technique (Determine 4). A customer-centric focus is essential, and it’s not at all times intuitive who the shoppers are. For instance, prospects for many energy plant digital options will probably be inside to the corporate, reasonably than exterior. Operators and upkeep employees are sometimes the individuals who will profit most from know-how being deployed at an influence plant, so understanding their wants, preferences, and behaviors is critical to make sure the know-how chosen is an efficient match. Buyer insights and suggestions have to be used assist drive decision-making and form digital deployment for these initiatives to achieve success.

Given the speedy tempo of technological developments, digital technique should embrace agility and adaptability. It ought to permit for iterative and incremental enhancements, enabling the group to experiment, be taught, and pivot when crucial.

A knowledge-driven strategy is crucial. In different phrases, choices ought to have information behind them. This entails leveraging analytics, machine studying, and different data-driven applied sciences to extract insights, establish tendencies, and uncover alternatives for optimization and innovation.

A profitable digital technique prioritizes constructing organizational capabilities and fostering a digital tradition. It entails guaranteeing the mandatory expertise, abilities, and sources are in place to drive digital initiatives. It additionally promotes a tradition of innovation, collaboration, and steady studying, encouraging staff to embrace digital transformation.

Lastly, an efficient digital technique incorporates mechanisms for measuring and monitoring earlier than and after efficiency. It establishes key efficiency indicators (KPIs) aligned with strategic targets and repeatedly assesses progress. It also needs to embody concerns for safety and danger administration assessments. These hallmarks collectively contribute to a well-rounded digital technique that positions a corporation for achievement.

Taking the Subsequent Step

Know-how is consistently altering, and to maintain up, energy corporations should change too. Incorporating modern new digital know-how into all elements of a enterprise will enhance an organization’s backside line. Even earlier than a call is made so as to add a brand new asset to an organization’s portfolio, know-how can be utilized to judge choices and supply perception on one of the best path ahead. Digital options can be found to reinforce the planning, designing, and executing of tasks. As soon as visions turn into actuality, different options can enhance operations, upkeep, and safety. All through the complete asset lifecycle, know-how is the important thing to peak efficiency.

—Aaron Larson is POWER’s government editor.