Help for battery power storage, and manufacturing of apparatus for the electrification of transportation, is spurring building of battery factories throughout the U.S.

American Battery Manufacturing unit, a frontrunner in improvement of lithium iron phosphate (LFP) battery cells, lately introduced a partnership with Lead Clever Gear (LEAD) to safe customized automation gear and equipment that can be utilized in ABF’s first gigafactory in Tucson, Arizona.

Arizona is a well-liked spot for battery manufacturing. LG Power Resolution in early April introduced it will full a $5.5 billion advanced in that state, that includes two manufacturing amenities, which might be the corporate’s first standalone cylindrical and power storage system (ESS) battery crops in North America.

KORE Energy, in the meantime, is opening its KOREPlex battery manufacturing facility in Maricopa County, Arizona. Development of that mission started in 2022.

ABF held the groundbreaking for its facility in October of final yr, and in March of this yr stated its gigafactory would produce battery cells for quite a few purposes. The manufacturing facility will function a completely automated manufacturing line, constructed from the bottom as much as present a tailor-made answer for meeting. The manufacturing course of may have gear to cowl each key step of constructing battery cells, from mixing and coating to stacking and packaging. Equipment will embrace the slurry system, cathode and anode laser chamber, and turnkey line gear. LEAD will initially present onsite assist together with system set up, commissioning, and coaching.

ABF is working with U.S.-based firms to safe extra gear, constructing controls, software program, programmable logic controllers, cyber programs, building and extra. The corporate has beforehand introduced partnerships with Honeywell, First Phosphate, Anovion, Celgard, FNA Group, and Lion Power to supply an array of options together with digital platforms, lithium sourcing, anode and separator supplies, and battery pack integration.

The gigafactory is anticipated to be accomplished in 2025. It would embrace ABF’s headquarters, a analysis and improvement heart, together with the preliminary 2×2 GWh manufacturing facility module. The corporate stated the LFP battery cells produced onsite “can be distinct from different lithium battery chemistries, incorporating the most secure chemistry and environmentally pleasant design whereas lasting as much as 10,000 life cycles/30 years.”

“With the intention to be totally price aggressive, we’d like a vanguard, totally automated course of, and thru our collaboration with LEAD we will obtain this,” stated John Kem, president of American Battery Manufacturing unit. “That is actually important in our drive to make the most of precision scanning and synthetic intelligence to allow next-generation, good manufacturing in Pima County, Arizona. By creating a home LFP battery cell provide chain, we’ll enhance U.S. financial competitiveness, create high-paying high quality jobs and assist meet nationwide safety and sustainability objectives.”

ABF has stated its U.S.-made LFP battery cells are designed for deployment by battery pack integrators and power storage answer suppliers throughout a spread of markets, together with utilities, knowledge facilities, telecommunications, industrial/agricultural gear, energy instruments, specialised markets and nationwide protection necessities.

Kem lately supplied POWER with perception into his firm, its manufacturing plans, the Arizona manufacturing facility, the outlook for battery manufacturing, and the marketplace for battery power storage.

POWER: Are you able to communicate to your background and the way that impacts your position as president of ABF?

Kem: I spent 35 years within the U.S. Military and retired as an Military two-star basic, with my last place because the commandant of the U.S. Military Struggle School. I used to be lucky to guide a number of massive, advanced organizations, together with the Northwestern Division of the Military Corps of Engineers, which runs the biggest hydropower manufacturing system within the U.S. (Columbia River and Missouri River programs). I hope I convey management, perspective and a capability to create a constructive local weather and tradition to drive to success.

POWER: What updates are you able to present in regards to the building of the gigafactory in Arizona?

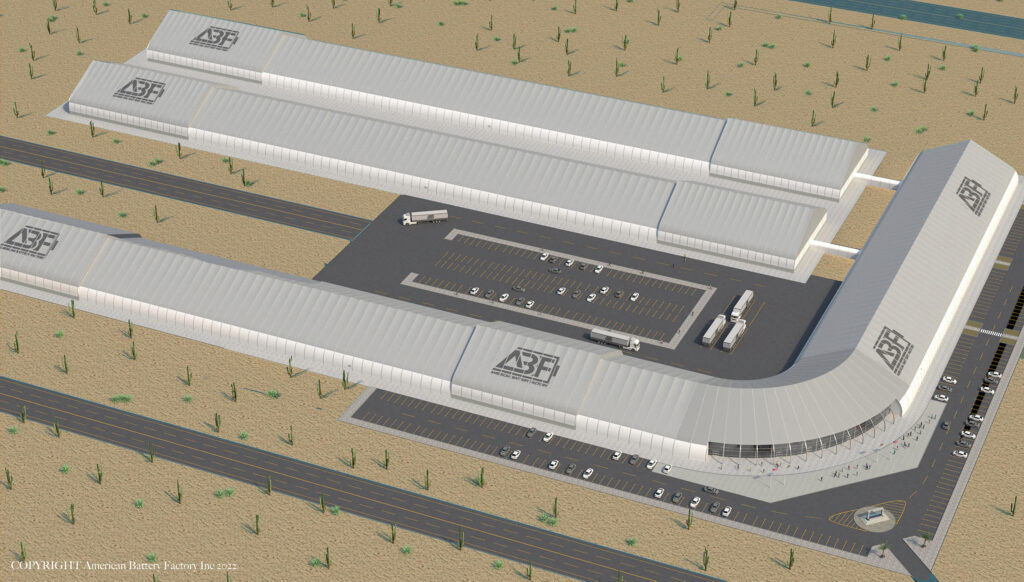

Kem: In Part 1, ABF is constructing a 4-GWh lithium iron phosphate battery cell manufacturing facility and an adjoining 0.5-GWh innovation-foundry line simply south of Tucson, Arizona, in Pima County. For Part 2, ABF will construct three extra 4- to 5-GWh factories to convey the advanced to ~18 GWh on a complete of 267 acres in Pima County, that has already been acquired in a lease-to-buy association.

We now have achieved the preliminary groundbreaking in Tucson and have agreements and plans in place for the important thing infrastructure. Tucson Electrical Energy has established an settlement for preliminary 46-kV transmission traces by February/March 2025. We now have an agreed-upon website plan that accesses the close by Raytheon Parkway for fundamental street entry, and a close-by railhead for Part 2 ranges of manufacturing.

The primary constructing will not be advanced building. Will probably be greater than 1,500-feet lengthy, and about 160 toes huge. However the principle manufacturing line is extremely automated gear and warehouse administration.

POWER: What distinctive battery chemistry can be utilized in manufacturing?

Kem: The chemistry (LFP and artificial graphite) will not be distinctive to the trade, however our superior cell design together with Z-folding construction can enhance the facility density and security, charging/discharging charge, and acquire lengthy cycle life. The cell chemistry may also evolve with among the new chemistries (like LMFP with 20% extra power) as we experiment with convey new lab outcomes to scale manufacturing. (Editor’s observe: LMFP is a kind of lithium-ion battery that’s made primarily based on LFP, however changing among the iron used because the cathode materials with manganese.)

ABF will make the most of at the moment utilized state-of-the-art manufacturing gear and can work carefully with established U.S. companions like Honeywell, Lead Clever Gear and extra to be introduced, all of whom have depth of data, experience, and capabilities in sensing and controls, exact measurements and manufacturing, robotics, and automation. In consequence, ABF will set up a brand new era of cell manufacturing traces with excessive power effectivity, excessive reliability and high quality management as a result of implementation of recent power, digital expertise, and exact and robotic controls. These efforts will reestablish the potential and financial competitiveness of U.S. manufacturing, at scale, and develop U.S. expert manufacturing workforce improvement.

POWER: What design will these battery cells implement? How shut are we to manufacturing?

Kem: ABF owns the entire engineering bundle of cell design and manufacturing. We now have simply chosen the principle gear manufacturing gear and are working to finalize the tens of hundreds of thousands of {dollars} of auxiliary and supporting gear. Manufacturing gained’t begin till late 2025.

POWER: What number of cells have been manufactured up to now?

Kem: Till the principle manufacturing line is constructed south of Tucson we don’t have any U.S. manufacturing. We do have a small pilot line (just a few hundred MWh of cells per yr) in China that we personal. We’re utilizing it to allow us to experiment with enter supplies from U.S. and North American suppliers to validate the fabric as we work on U.S.-centric materials inputs.

POWER: What’s ABF’s present manufacturing capability? What does the long run appear to be for the corporate?

Kem: LFP prismatic cells are among the many most engaging candidates for power storage as a result of they’re decrease price, use plentiful components, have decrease toxicity, are safer, supply steady biking efficiency, and have a decrease carbon footprint. For these causes, ABF’s fundamental manufacturing can be LFP cells.

POWER: How will ABF battery cells be used?

Kem: Sadly, non-public sector company efforts have nearly solely targeted on electrical automobile (EV) batteries for automotive functions, and largely U.S. last meeting of EV battery packs and restricted U.S. up-the-chain provide efforts. That’s the reason ABF could make an amazing distinction within the nation’s manufacturing efforts. Moreover, we’re assured that this effort to assist ‘specialised and small markets’ (like non-heavy-duty automobiles, agricultural, mining and navy purposes) will end in important positive aspects for the U.S. as home electrification efforts over the subsequent 5 years are anticipated to dramatically improve demand from U.S. corporations at a CAGR (compound annual progress charge) of 28.0% from 29 GWh in 2020, to 1,151 GWh in 2035.

POWER: Are you able to give me an replace on uncooked materials sourcing and subsequent steps for ABF?

Kem: ABF has been working with North American suppliers for each future key supplies provide and important bulk minerals, and has signed alliance agreements or MOUs (memorandums of understanding) with a number of suppliers within the U.S. or Canada. ABF can be in dialog with many North American suppliers for cathode/anode supplies, separators, electrolytes and cell enclosures to additional safe the supplies provide.

POWER: Are you able to communicate to plans for ABF’s recycling course of?

Kem: In cooperation with Pima County, we anticipate the event of a Nevada Know-how Corp. battery recycling heart on or adjoining to our property. ABF can be partnering with a few U.S. recycling companions to instantly recycle manufacturing scraps and get well the cathode and anode supplies that can be utilized in cell manufacturing.

—Darrell Proctor is a senior affiliate editor for POWER (@POWERmagazine).