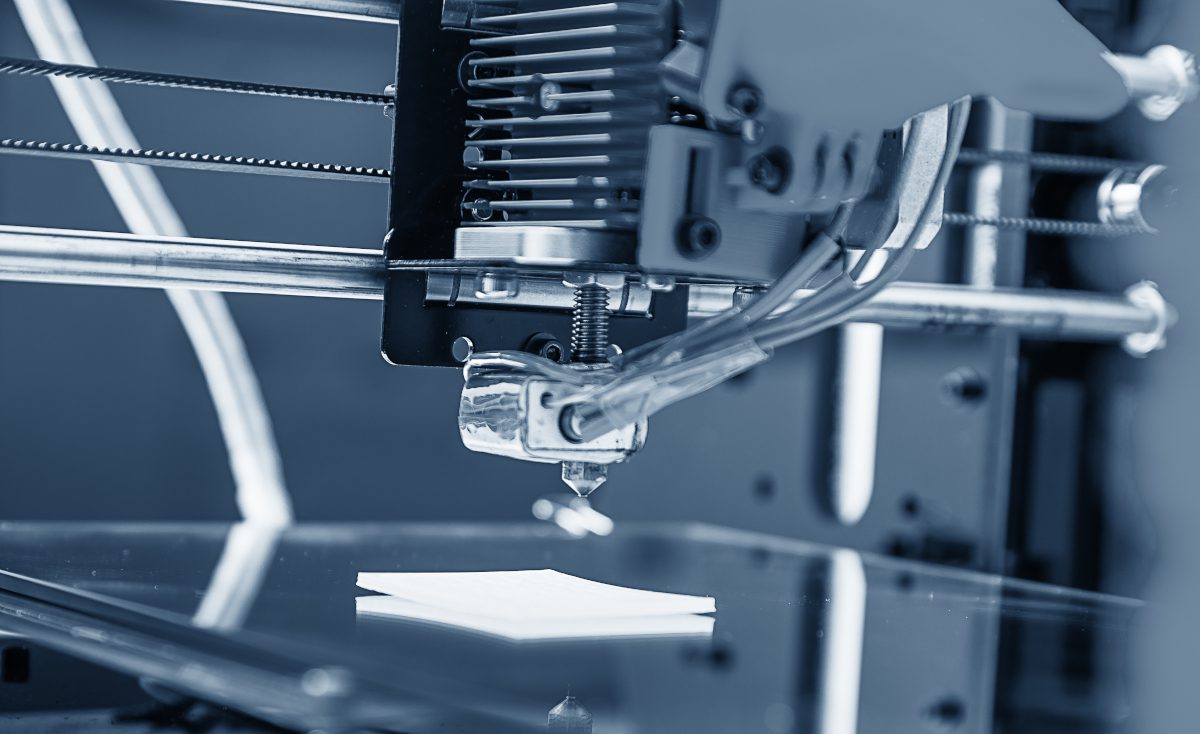

Researchers have found a technique to remodel a big waste output from soy biodiesel crops right into a useful useful resource. The workforce behind it has developed a course of to transform matter natural non-glycerol (MONG), a byproduct of biodiesel manufacturing, into copolymers appropriate for 3D printing filaments.

The worldwide demand for renewable power sources has led to a rise in biodiesel manufacturing, leading to a big quantity of waste byproducts corresponding to MONG. Historically, MONG has been landfilled, posing environmental challenges and financial inefficiencies. The research presents a two-fold answer: a way to stabilize MONG to be used in 3D printing and a discount within the artificial polymer content material of pure fibre composites (NFC).

The researchers characterised soy MONG and evaluated its potential as a copolymer to supply 3D printing filaments. They targeted on enhancing the thermal stability of MONG via two pretreatments: acid remedy and a mix of acid and peroxide. The latter resulted in a stabilized paste with decreased cleaning soap content material, elevated crystallinity, and the formation of low molecular weight small chain fatty acids, making it a super candidate for copolymerization with thermoplastic polymers.

The research’s findings point out that acid and acid + peroxide remedies successfully cut up cleaning soap, scale back water solubility, and improve glycerol content material in MONG. The remedies additionally facilitated the oxidation of fatty acids and the formation of small chain fatty acids, that are extra appropriate for 3D printing purposes. Notably, the acid + peroxide remedy led to a rise in formic acid and oxirane focus, suggesting profitable epoxidation, a key issue for enhancing the thermal stability of MONG.

The researchers additionally carried out a complete evaluation of the MONG’s physicochemical properties, fatty acid profile, and thermal stability. The outcomes have been promising, exhibiting that handled MONG could possibly be a viable various to artificial polymers in NFC for 3D printing. The research concludes that the utilization of MONG in 3D printing not solely provides worth to a biodiesel waste product but additionally contributes to the event of sustainable and carbon-neutral composites.