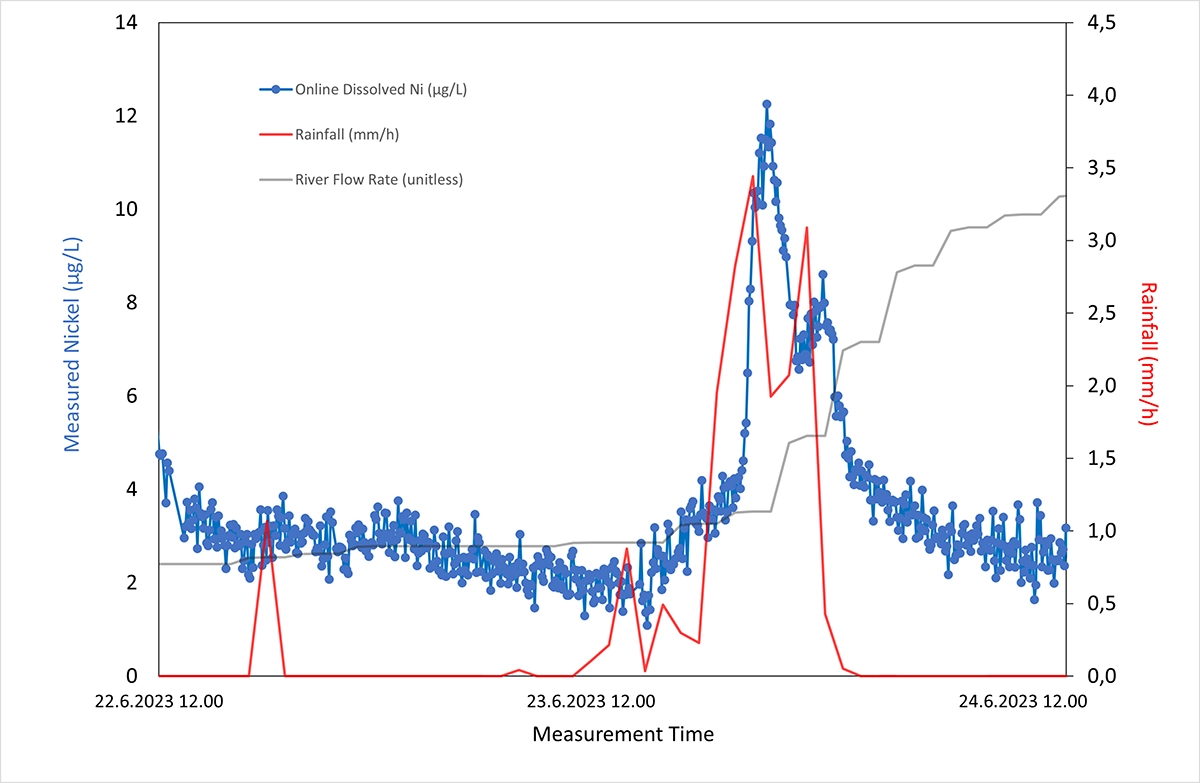

A brand new steady metals monitoring expertise was not too long ago trialled at a river by a Talc manufacturing plant in central Finland. The trial was performed to evaluate the potential for avoiding the necessity to pattern and analyse giant numbers of environmental water samples. “The outcomes have been extraordinarily enlightening,” explains Jari Sirviö, Improvement Engineer for Elementis, the plant’s proprietor. “Fortunately, a heavy rainfall occasion occurred in the course of the transient trial, and we found a fast improve, and subsequent lower, in nickel focus that intently adopted the rain. This robust correlation between rainfall and nickel gives an essential perception into the behaviour of nickel, and raises plenty of essential questions; it additionally highlights the large advantages that may be gained from steady monitoring.”

It’s common apply globally, to observe metals concentrations by sampling for laboratory evaluation, and the plant had beforehand taken samples 3 times per week. In distinction, the continual and automatic monitor makes a measurement each 5 minutes, 24/7. “Lab evaluation wouldn’t have been in a position to exhibit the correlation between rainfall and nickel focus,” Jari explains. “We’re due to this fact delighted to see that this new monitoring expertise can ship better insights into the elements affecting water high quality, in order that we will constantly enhance our environmental efficiency.”

The brand new monitoring expertise employs Micro-Discharge Optical Emission Spectroscopy (µDOES®), and was equipped by the Finnish firm Sensmet.

Background

Using over 1,300 folks at greater than 24 places, Elementis is a specialty chemical substances firm with operations worldwide. The corporate is concentrated on distinctive, high-value options and merchandise to enhance efficiency and improve sustainability for patrons within the private care and product efficiency specialties markets. The Elementis plant at Sotkamo produces Talc in line with market demand, in addition to Nickel focus as a by-product.

Talc is without doubt one of the softest minerals, and with platy and hydrophobic traits it provides worth to a variety of business merchandise together with paper, paints & coatings, polyester putties, plastics, ceramics, meals, and fertilizers.

Nickel is utilized in a variety of business functions such because the manufacture of stainless-steel. Nonetheless, its significance has been heightened in recent times as a element of rechargeable batteries – in electrical autos for instance.

Environmental monitoring

Elementis continually goals to design higher merchandise that use much less assets and create much less air pollution. As well as, the corporate has recognized water administration, waste minimisation and ecological impacts as materials points inside its sustainability technique.

A water remedy plant was constructed on the Sotkamo facility in 2021, utilizing lime to lift the pH of website wastewaters and take away contaminants equivalent to metals. In compliance with an environmental allow, along with Finnish environmental regulation, top quality course of monitoring ensures the receiving atmosphere will not be polluted by the discharge, and consists of an higher restrict for nickel within the receiving river water of 0.034 mg/l.

In the course of the interval instantly after the set up of the neutralisation plant, a lot of laboratory samples have been taken because the plant was optimised. This prompted Elementis employees to analyze the potential for steady evaluation, which led to the trial of Sensmet’s µDOES® analyser.

Steady multi-metal monitoring expertise

Sensmet’s Micro-Discharge Optical Emission Spectroscopy, µDOES®, allows the multi-metal real-time evaluation of aqueous samples. Along with nickel monitoring, the expertise may also be utilised to observe components equivalent to lithium, sodium, cobalt, manganese, nickel, copper, and extra.

The patented µDOES® expertise relies on atomic emission spectroscopy. A micro-discharge (electrical spark) is created straight contained in the aqueous pattern, inflicting a microscopic quantity of the fluid surrounding the spark to be flash-heated to 10 000 °C. Molecules within the micro-discharge are dissociated into atoms, that are excited to their respective larger digital states. Upon returning to their floor state, these atoms launch their extra power by emitting gentle at their attribute wavelengths. The µDOES® measures this atomic emission spectrum to derive quantitative evaluation of the pattern, displaying measurements regionally, and transferring knowledge to the person’s DCS and database as wanted.

Conclusions

The µDOES® analyser has offered the Sotkamo employees with new insights into the elements affecting nickel ranges, which allows the event of mitigation measures. “Sensmet’s steady monitoring expertise has delivered an actual lightbulb second for us,” Jari Sirviö explains. “Now that we all know in regards to the correlation between rainfall and nickel focus, we will examine a variety of choices that could possibly be employed to decrease nickel ranges, and with steady monitoring we can be in a greater place to judge the outcomes.”

Lately there was a worldwide pattern towards better use of steady environmental monitoring. “This has been enabled by advances in expertise,” explains Sensmet CEO Dr Toni Laurila. “Nonetheless, as this trial has demonstrated, steady monitoring delivers a variety of different essential benefits, that mix to additional enhance environmental safety.”