On this article we discover the present use of hydrogen in industrial processes, in addition to its function within the ongoing international transition to a net-zero economic system. We’ll present insights into market alternatives and challenges, the newest processing applied sciences, and greatest practices in security to assist business stakeholders as they face mounting stress to scale up hydrogen manufacturing.

Hydrogen could be very harmful. At each level throughout its worth chain, upstream and downstream, hydrogen stays extraordinarily flamable and may explode in confined areas when uncovered to any electrical tools producing arcs, sparks, or extreme warmth. Consequently, accurately licensed explosion-proof electrical tools is required as outlined within the NFPA 70 Nationwide Electrical Code (NEC Article 500), amongst others, relying on geography. For the needs of this text, we’ll think about NEC necessities for hydrogen, particularly Class I, Division 1 or 2, Group B.

The Hydrogen Market

Based on the Worldwide Power Company, hydrogen represents “the largest innovation alternative” to cut back or eradicate carbon dioxide (CO2) emissions produced by human exercise. Hydrogen’s potential to interchange fossil fuels with out releasing CO2 when consumed has led to new functions being explored on quite a few fronts, notably gasoline cell electrical autos. Bolstering these initiatives, the U.S. Division of Power (DOE) in 2023 introduced an funding of $7 billion to launch seven Regional Clear Hydrogen Hubs to speed up the commercial-scale deployment of low-cost, clear hydrogen.

Whereas inexperienced improvements like these maintain nice promise, hydrogen instead power represents solely a small sliver of total consumption. Of the 120 million metric tons (MMT) of hydrogen consumed worldwide in 2022, the overwhelming majority was concentrated within the conventional sectors of petroleum refining and chemical processing.

Globally, annually roughly 55% of hydrogen goes into the creation of ammonia for fertilizer, one other 25% into petroleum refining hydro-desulfurization and hydrocracking operations, 10% to provide methanol, and the remaining 10% in treating metals, flat glass manufacturing, chemical synthesis of plastics, and the manufacturing of semiconductors. Gaseous hydrogen can be utilized as a coolant for turbines as a result of its excessive thermal conductivity. Virtually all of the hydrogen produced within the U.S. is used for refining petroleum, treating metals, producing fertilizer, and processing meals.

Hydrogen Manufacturing

Hydrogen is the only and lightest of all Earth components, consisting of just one proton and one electron. It is usually essentially the most considerable aspect within the universe, but not often in its pure state. As an alternative, hydrogen covalently bonds to one in all three components: fluorine, oxygen, or nitrogen. To provide hydrogen as gasoline, it have to be separated from the opposite components within the molecules the place it happens. Applied sciences allow the separating of hydrogen gasoline from its companion substances in purities within the order of 99.999%.

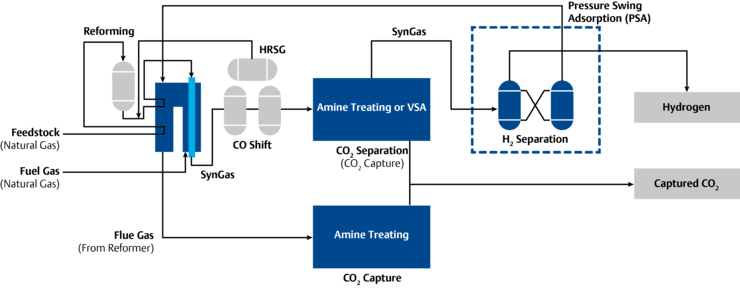

Hydrogen is sort of completely produced via thermochemical processes requiring fossil fuels: hydrocarbon reforming, coal gasification, hydrocarbon pyrolysis, and plasma reforming. Roughly 95% of hydrogen is produced through steam reforming of hydrocarbons (Determine 1) with the steadiness coming from water electrolysis, biomass-derived liquid reforming, and microbial biomass conversion.

The least costly methodology of manufacturing is steam methane reforming (SMR). In addition to methane, it’s used to provide hydrogen from ethanol, propane, and gasoline. Though steam refining could be very cost-effective, it requires fossil fuels as feedstock and to provide warmth. In reality, for each kilogram of hydrogen produced in SMR, seven kilograms of CO2 are launched into the setting. Carbon seize and storage (CCS) strategies search to lure the overwhelming majority of CO2 produced by SMR and retailer it within the floor, changing the product from “grey” to “blue” hydrogen (see sidebar).

| Hydrogen Manufacturing Colour Codes

Totally different strategies of manufacturing hydrogen are sometimes referred to by sure colours:

|

A substitute for steam refining is water electrolysis. This pathway splits hydrogen from water utilizing electrical present, successfully changing electrical power into chemical power. Relying on the form of electrolyte materials and ionic species getting used, electrolysis is carried out utilizing one in all three forms of electrolyzers: alkaline, strong oxide, or proton trade membrane (PEM).

Like steam refining, electrolysis largely depends on fossil fuels. The one manner the method is CO2 impartial—that’s, it produces virtually no greenhouse gases or different pollution—is when renewable power sources are employed, comparable to wind or photo voltaic. As a result of this “inexperienced” hydrogen method is significantly dearer than hydrogen sourced from fossil fuels, it makes up lower than 0.04% of all hydrogen produced globally.

Hydrogen Storage

Hydrogen could also be bodily saved as a gasoline (Determine 2) or a liquid, but each strategies current challenges. Low power density and the complexities of cryogenics are a number of the largest obstacles. Hydrogen gasoline is vulnerable to leakage. It may permeate via strong metals, in addition to embrittle metals, which impacts the integrity of storage and transportation infrastructure by creating cracks. Even a tiny leak can result in the buildup of harmful hydrogen clouds in a confined space or inside an enclosure.

One other storage possibility is to chemically bind hydrogen with solids or liquids capable of soak up it. Lastly, there’s the underground storage of hydrogen. Bulk storage of uncompressed hydrogen has confirmed viable in salt caverns, and to a lesser extent in porous media comparable to sandstone or shale, and in engineered cavities.

Hydrogen Transportation

Most hydrogen used within the U.S. is produced at or near the place it’s consumed—sometimes at petrochemical or chemical websites. If it isn’t consumed at its point-of-production, hydrogen could be transported to its point-of-use by railcar, barge, or over the highway in gaseous tube trailers or in cryogenic liquid tanker vehicles.

Lengthy-distance pipeline investments have been made in areas the place there’s a vital, regular demand for hydrogen. Within the U.S., there are roughly 1,600 miles of lively pipeline for hydrogen transportation, 90% of which is positioned alongside the Gulf Coast of Texas, Louisiana, and Alabama, serving refiners and ammonia vegetation. Pipelines are the least costly methodology of transporting hydrogen.

Hydrogen Fires and Explosions

When growing electrical methods for a hydrogen software, engineers should concentrate on its related risks and the necessity for correct hazardous space classification for electrical tools. Make no mistake—there are severe security issues when hydrogen is launched in ample concentrations, a scenario made extra precarious as a result of hydrogen is each colorless and odorless.

Hydrogen’s extensive flammability vary (4% to 74%) means the power wanted to ignite it may be very low, like that generated by a small spark or an electrostatic discharge. Due to this fact, all electrical tools have to be bonded and grounded. Any tools that isn’t accepted for hazardous environments by the NEC, IECEx or ATEX have to be stored exterior of the designated space.

One other hazard of hydrogen is that its flames burn at extraordinarily excessive temperatures (500C, 932F), but, principally exterior of the seen mild spectrum, making these fires each extraordinarily damaging and practically unimaginable to initially detect. Moreover, at concentrations of 18.3% to 59%, hydrogen will explode. Blast waves from a hydrogen explosion could cause very severe injury to surrounding buildings in addition to accidents to close by personnel.

Explosive forces will fluctuate relying on a number of components, comparable to the amount of gasoline, the presence of some other supplies, and the circumstances beneath which the explosion happens together with container geometry. The DOE Workplace of Power Effectivity and Renewable Power classifies hydrogen explosions as being both deflagrations or detonations (see sidebar).

| Sorts of Hydrogen Combustion: Deflagration Versus Detonation

The next evaluate and distinction deflagrations and detonations:

|

Hydrogen has one security benefit over different flammable fuels: hydrogen is 14 instances lighter than air and rises six instances sooner than pure gasoline, which signifies that it disperses quickly when launched. Except leaking hydrogen is contained by a roof or another construction, it would rapidly disburse earlier than it reaches a flammable focus. The legal guidelines of physics forestall it from lingering close to a leak in contrast to heavier gases comparable to propane or gasoline fumes. For that cause, hydrogen explosions and fires are most certainly to happen in confined, poorly ventilated areas the place hydrogen is processed or saved in giant portions.

Mitigating Hydrogen Dangers

In North America, electrical methods put in in hydrogen functions observe NEC Article 500, as beforehand talked about. The NEC is integrated into most state and native jurisdiction rules and due to this fact carries the load of regulation.

In Article 500, 502, and 503, the NEC particulars its Class (nature of the hazardous materials) and Division (chance of existence of it) system, which is additional delineated into Teams (the kind of hazardous supplies). The NEC Class/Division System for hazardous areas classifies hydrogen functions as being Class I, Division 1 or Division 2, Group B (Determine 3).

A Class I space is outlined by the NEC as, “Areas that are deemed hazardous as a result of presence of gases or vapors which are current within the air in a ample amount to provide explosive or ignitable mixtures.” It will apply to most areas the place hydrogen is produced, saved, transported, or disbursed.

Class I hazardous areas are subdivided into Divisions. Division 1 is a Class I location “the place the hazardous ambiance is anticipated to be current throughout regular operations on a steady, intermittent, or periodic foundation.” Division 2 is a Class I location through which “risky flammable liquids or gases are dealt with, processed, or used however through which they’d usually be confined inside closed containers or closed methods from which they’ll escape solely within the occasion of an unintended rupture or breakdown of the containers or methods.”

Divisions are damaged down into seven teams (A, B, C, D, E, F, and G), though three (E, F, and G) refer solely to mud and never gases. Information pertaining to flamable vapors and gases in figuring out Group are its flash level, higher/decrease flammable limits, auto-ignite temperature, density, and stress, in addition to its MIE (minimal ignition power), MIC (minimal igniting present), and MESG (most experimental protected hole).

Hydrogen falls into Group B. Group B is an space that accommodates a flammable gasoline, liquid-produced vapor, or flamable liquid-produced vapor blended with air that has the potential to catch hearth and burn or explode. The weather on this Group have an MESG worth equal to or lower than 0.45 millimeters or an MIC ratio equal to or lower than 0.40. In addition to hydrogen, different Group B gases embrace butadiene, ethylene oxide, propylene oxide, and acrolein.

Making use of due diligence within the classification, design, and set up per the relevant code will render hydrogen no extra harmful than some other product. We’ll additionally be aware right here that the appliance of air flow might change {the electrical} necessities in hazardous areas the place hydrogen is current, as can partitions, ceilings, and flooring as separation between categorised and non-classified areas. If followers are getting used, vent fan blades must be constructed with aluminum, plastic, or different non-sparking materials.

| Hazardous Space Technique

The next security steerage is really helpful:

|

Explosion-proof Gear Design

Explosion-proof tools for Class I, Division 1 or 2, Group B functions are designed and manufactured sturdy sufficient to comprise an explosion and forestall the escape of a flame or warmth that might ignite the encompassing ambiance. Burned gases do escape from explosion-proof tools. Nevertheless, their escape path has been engineered so the temperature of the escaping gasoline is properly under its ignition level when it escapes into the encompassing ambiance. This may be accomplished in a number of engineering strategies relying on the product, comparable to labyrinth-path and floor joint building.

Different technique of guaranteeing tools is explosion-proof are sealing it to stop entry of flammable gasoline, encapsulation in resin or oil immersion, pressurization with inert gasoline to displace hazardous substances, or limiting the temperature of its exterior surfaces. Electrical tools subjected to this setting should additionally present safety from the ingress of liquids or mud to take care of correct operation.

Decreasing the chance of hydrogen explosions and fires requires classifying areas of the operation as hazardous. As a result of hazardous space classification could be a advanced and daunting activity, seek the advice of NFPA 70 (Nationwide Electrical Code), NEC Articles 500–516, and NFPA 497 “Advisable Apply for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Categorised) Areas for Electrical Installations in Chemical Course of Areas.”

—Bogdan Moldovan is product advertising and marketing supervisor, Emerson Automation, Appleton.