A current engine and management panel improve by CHP assist specialist Gen-C to Avocet Renewables’ 500 kW biogas plant at Coston Corridor Farm in Norfolk has delivered a 20% improve in energy technology and enabled 24/7 distant monitoring and administration of the system.

This put up contains sponsored content material produced in collaboration with Gen-C.

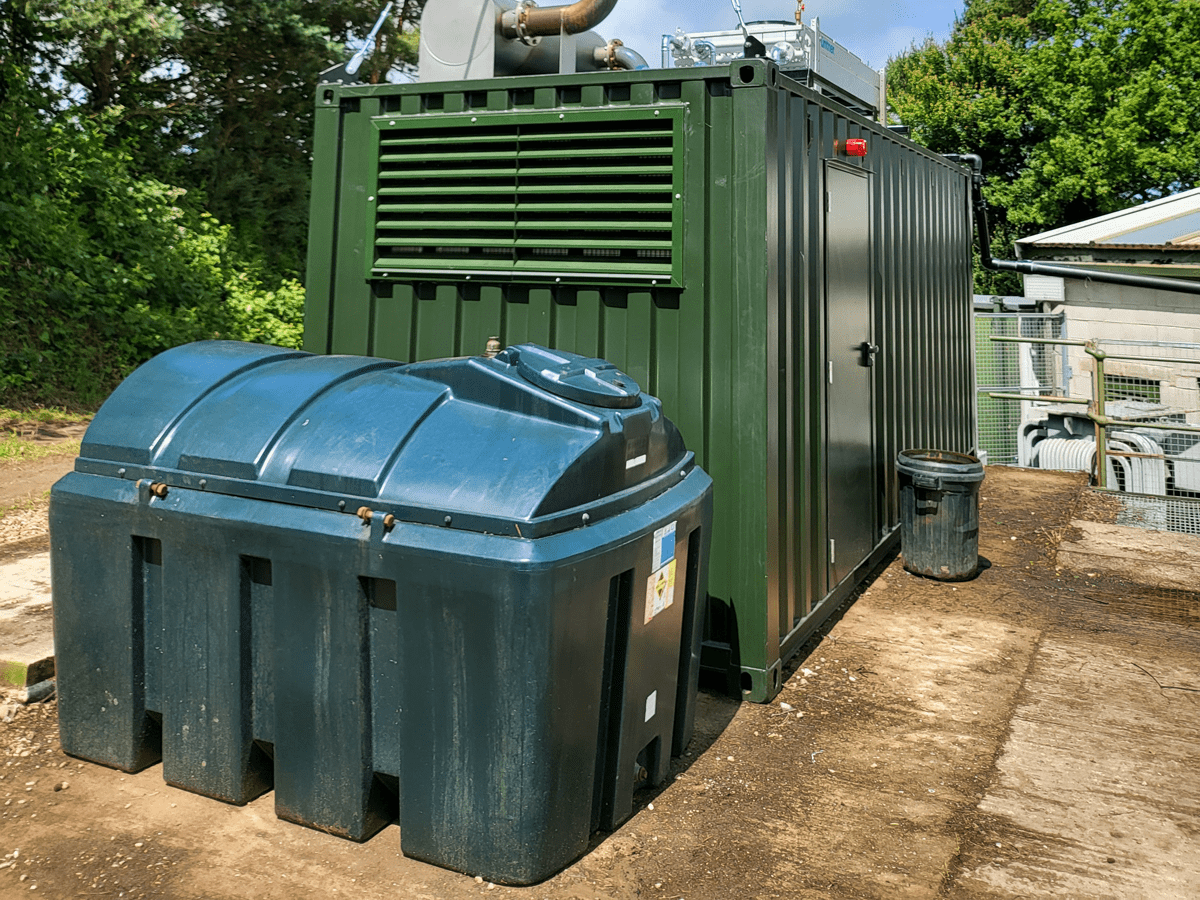

The Avocet Renewables’ anaerobic digestion (AD) plant at Coston Corridor Farm, Barnham Broom close to Norwich makes use of agricultural feedstocks reminiscent of power crops to generate biomethane and electrical energy, which is exported to the grid, in addition to warmth, which is used regionally on the farm for crop drying. The five hundred kW V12 MAN E3262 engine was put in in 2017 to supply warmth and generate electrical energy. Following a technical situation, Peterborough-based GenV Ltd had been introduced in to service and assist the engine. Nonetheless, points reminiscent of a locked management panel meant that GenV had been restricted of their potential to optimise CHP efficiency, so turned to assist companions Gen-C for assist.

Restricted by legacy controls

“The management system was previous, and since it was locked to the unique provider we had no entry to vary key elements of how the engine ran, and we couldn’t entry something remotely,” explains Warren Vessey, Managing Director at GenV. “After struggling for 18 months with failing engine efficiency, we carried out a full R3 service and agreed with the consumer to undertake a lot of upgrades, together with a brand new open-access management system, with the assistance of our long-term accomplice, Gen-C.”

In addition to changing and upgrading the management panel, Yorkshire-based Gen-C had been additionally commissioned to improve the engine in a bid to revive misplaced energy output and enhance reliability.

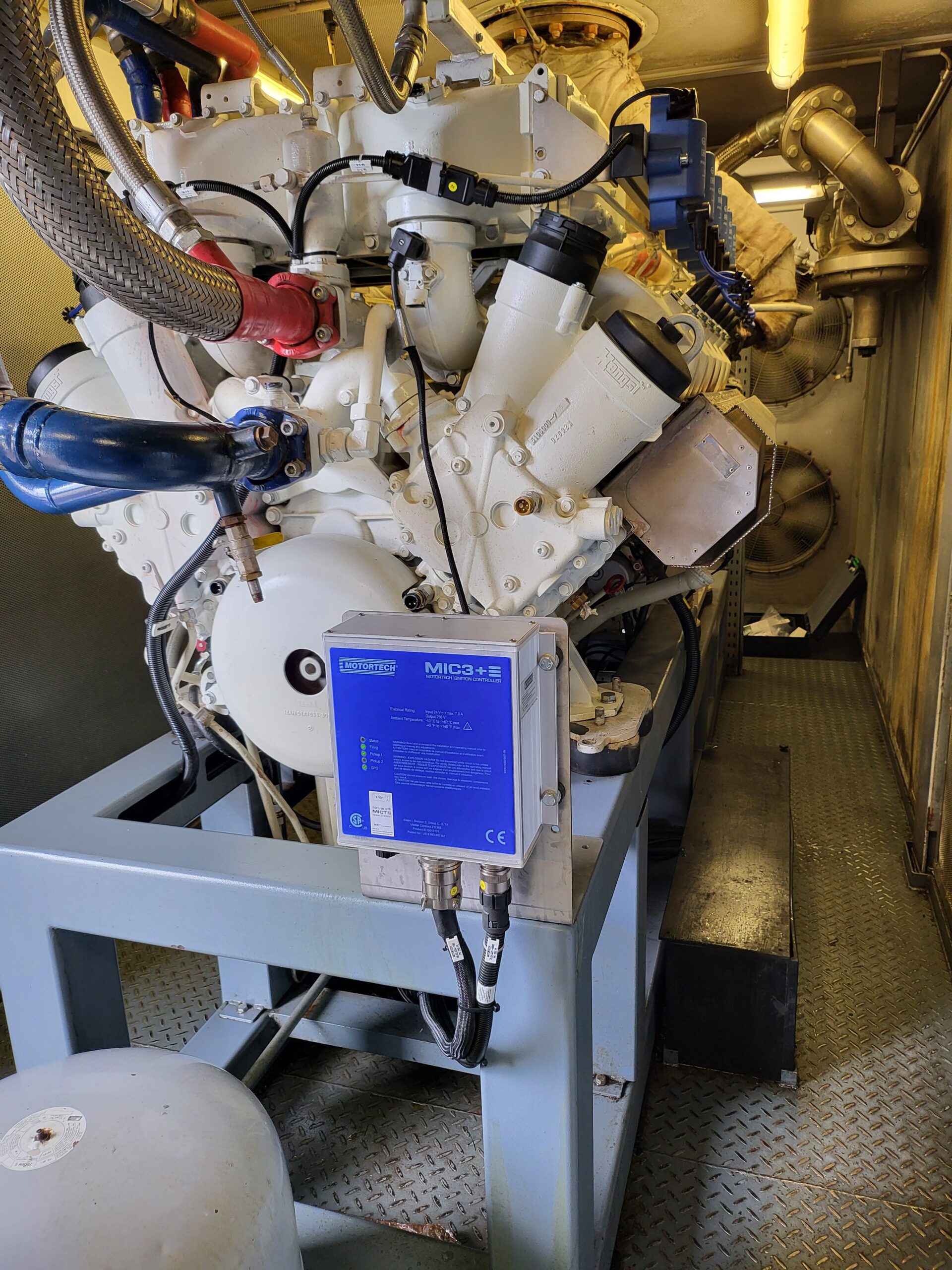

“The engine was underperforming – producing solely round 400 kW – misfiring and vibrating badly, so the consumer was dropping appreciable income” says James Thompson, Managing Director of Gen-C. “The engine was additionally comprised of a combination of kit from various manufacturers, which is one thing we see very often – the ignition controller, actuator, gas mixer, pick-ups and many others. had been from completely different producers, which was impacting efficiency.”

Streamlining CHP operation

James continues: “To enhance general efficiency, we upgraded the important thing parts such because the mixer and throttle pace management. And since every little thing we set up comes from one producer (main German model Motortech), the consumer now has a single level of contact for all servicing and spares – as we’re the only Motortech agent for the UK. We concurrently eliminated the previous controllers and display within the management panel and put in a brand new contact display with our controllers and enlargement playing cards.

“The brand new open-access management system means the AD operator, GenV and ourselves can all entry the system remotely and make rapid adjustments as required, preserving downtime to a minimal. The system additionally options good diagnostics, with alerts based mostly on user-defined parameters, and is backed by our 12-months free distant technical assist.”

Advantages of distant entry

Essentially the most rapid profit loved by Avocet Renewables following the engine improve is that their CHP is as soon as once more operating at full energy, offering a 20% uplift in output. With the brand new parts designed to final for at the least the following ten years, the engine can also be working extra easily which can enhance reliability, minimize downtime and scale back servicing necessities.

“The open protocol on the brand new management panel offers us full entry to the engine through distant monitoring. Meaning I can see every little thing that’s occurring and might help the Coston Corridor Farm website at any time, from wherever I’m, making it much more environment friendly and simpler to make use of,” stresses Warren Vessey.

“One other huge benefit for the consumer is that they now have full flexibility and selection over who handles their upkeep contract. It’s an industry-known system with available elements and assist, so anybody can entry it. It’s consumer pleasant and modifications or changes might be comprised of wherever, which actually helps to restrict downtime.”

The improve was solely accomplished in mid-June, however Mark Gill, Plant Supervisor at Coston Corridor Farm, is already optimistic: “The system works properly and is lots speedier than the previous management panel. It’s additionally a lot simpler to function and, most significantly, our CHP is working at full energy once more.”