Surely, the longer term for bucket vans is shiny, with important development projected for the class partially because of the intensive infrastructure improve applications which were authorised within the U.S. and overseas. One doable barrier to this development is the truth that these vans are costly. They value quite a bit to buy and preserve. Nonetheless, there are a selection of truck design enhancements which might be considerably decreasing complete value of possession (TCO) whereas concurrently bettering security, gasoline effectivity, and environmental affect. This text addresses a type of enhancements—electrical energy take-offs (ePTOs).

Whereas totally electrical bucket vans aren’t frequent but, ePTOs enable hydraulic raise features to be powered by an electrical motor as an alternative of a diesel engine. This permits operation of the increase with out idling, considerably bettering gasoline effectivity and lowering emissions. For firms targeted on greening their fleets, ePTO bucket vans present a smart first step towards electrification.

What Are ePTOs and How Do They Work?

Not like conventional PTOs, which finally pull energy from the truck’s engine, ePTOs function utilizing electrical motors and inverters. This permits the hydraulic raise and bucket features to be powered independently from the engine, eliminating pointless idling whereas the car is parked on the job web site. With the appropriate sensors and system structure, operators can interact the electrical motor when commanding perform motion from the bucket. This idea primarily permits the fleet to seize the power that will in any other case be spent by means of idling whereas the bucket and increase aren’t transferring, which, normally, represents the overwhelming majority of the car’s obligation cycle. This equates to lowered gasoline consumption, decrease emissions, and a quieter operation.

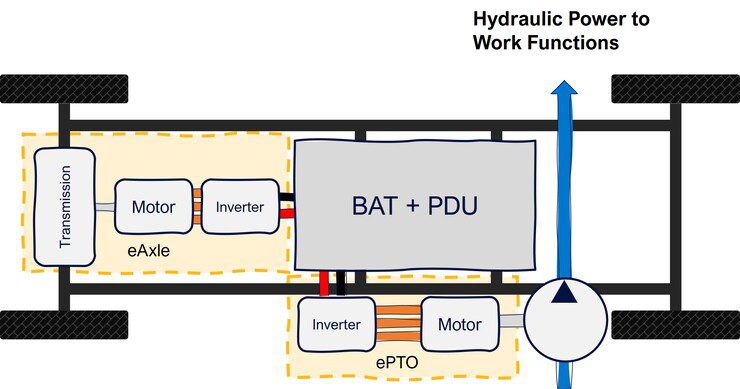

Usually, an ePTO system consists of a hydraulic pump, an electrical motor, and an inverter linked to a direct-current (DC) energy supply comparable to a battery. A chargeable battery powers the ePTO (Determine 1) and is designed to carry its cost lengthy sufficient for the operator to finish a day’s work. Bucket vans are a super software for this know-how, as most return to a base on the finish of the day the place they are often recharged in a single day when power prices are at their lowest.

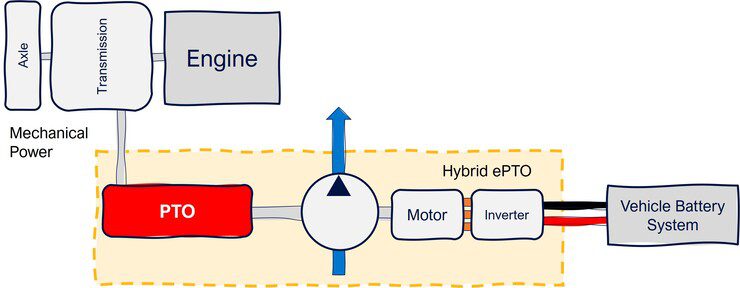

Nonetheless, if the truck wants to remain on a job web site for a number of days, then a hybrid car strategy could make sense to leverage each the power capability of a gasoline tank and the power-on-demand idea realized with an ePTO. This technique structure consists of each a standard PTO and an ePTO driving the identical pump, illustrated in Determine 2.

When the operator works the truck lengthy sufficient to deplete the battery provide, the engine will kick on and interact the PTO. At that time, the pump is being pushed by the engine. Nonetheless, as a result of the electrical motor stays coupled with the pump, it begins working as a generator by utilizing the remaining obtainable engine energy to cost the battery. As soon as the battery is re-charged to a suitable degree, the PTO disengages from the engine and the system returns to engine-off operation.

Emissions Discount

Making the swap from a standard PTO to an ePTO is trending as a result of it considerably reduces idling, which, over your complete obligation cycle, can actually add up in emissions decreases, relying on how the car is getting used. Take into account, for instance, the case of a 37,000 GVWR (gross car weight score) bucket truck that makes use of 1.5 gallons of diesel per hour whereas idling with the PTO. If a bucket truck idled to energy a standard PTO six hours a day, 5 days every week, over the course of a 12 months it could burn 2,340 gallons of diesel.

Burning diesel gasoline emits 22.45 kilos of CO2 per gallon, which means only one bucket truck may scale back carbon emissions 5,253.3 kilos just by leveraging the power-on-demand advantages of the ePTO. However idling apart, electrical motors and inverters collectively are considerably extra environment friendly in transferring energy than an inside combustion engine, which implies you’re additionally slicing the power consumption by a 3rd when perform motion is required.

Decrease Upkeep Prices

Past lowering emissions, ePTOs may also assist scale back upkeep prices. When a truck idles to energy a standard PTO, engine hours could counsel it’s time for upkeep, regardless that the truck could not have traveled sufficient miles to warrant service. Utilizing an ePTO, in distinction, requires zero engine hours, so bucket vans are maintained at correct intervals, and fleets spend much less on oil, components, and different provides, in addition to technician labor hours.

An ePTO additionally places much less stress on the engine, permitting fleets to increase the lifecycle with out rising upkeep prices. Slicing out idling additionally reduces gasoline prices. Within the instance above, the bucket truck geared up with an ePTO makes use of 2,340 fewer gallons of diesel per 12 months. At $4.50 per gallon, that’s a gasoline financial savings of greater than $10,000 per 12 months for a single truck. Over the lifetime of the truck, that’s a major discount in TCO.

Noise Discount

With an ePTO, bucket vans can moreover contribute much less to noise air pollution. Extreme noise doesn’t simply disturb the neighbors, it additionally creates security dangers if staff can’t clearly talk with one another on the jobsite.

As a result of a bucket truck’s engine doesn’t should run to function the increase, the one time an operator and others close by encounter engine noise is when the truck should transfer. With bucket vans, that’s not fairly often.

Ensuring pump and motor speeds aren’t under- or over-speeded is one approach to scale back this noise. Techniques may also be designed with dampeners, like rubber mounts and different dampening supplies, to additional scale back noise.

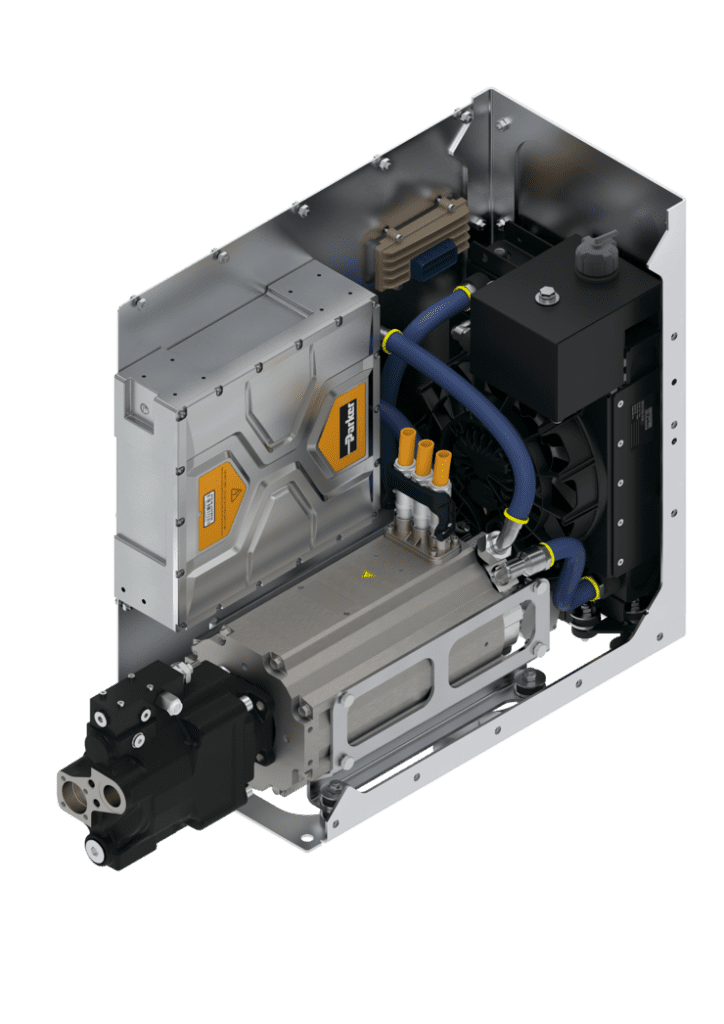

Pairing a quiet or zero-noise pump with an ePTO is a perfect possibility (Determine 3) for bucket vans that function in environments the place noise discount is necessary, like a residential space or golf course. With much less noise, these vans can work prolonged hours—even late into the night—till an issue is solved with out considerations about noise complaints.

ePTO Bucket Vans Are a Sustainable, Value-Efficient Possibility

As infrastructure and utility tasks ramp up globally, ePTO bucket vans present a sustainable, cost-effective approach to meet demand whereas bettering neighborhood relations. This know-how proves environmental and enterprise objectives can go hand in hand.

As you got down to design the subsequent technology of bucket vans, just remember to choose a producing accomplice that may present the parts and engineering experience to capitalize on the newest developments and applied sciences.

—Tom Hickey is a methods software engineer-Electrification for Parker Hannifin.