The research of geomechanics performs an important but underappreciated position in geothermal power, from wellbore stability to effectivity of hydraulic stimulation.

Geomechanics, the research of the mechanical habits of rocks and soils, performs an important position in creating and working geothermal power programs, notably in Enhanced Geothermal Programs (EGS) and Superhot Rock (SHR) initiatives. By understanding the stress state, rock power, and fluid circulation habits within the subsurface, geomechanics helps to optimize effectively design, hydraulic fracturing, and reservoir administration (Liu et al., 2022).

Whereas that is conceptually understood, there may be nonetheless some confusion of simply how beneficial and intensive geomechanics research may be throughout the geothermal trade. Within the worst case state of affairs, no geomechanical mannequin or an incorrect mannequin may result in improper wellbore therapy and wellbore loss, in the very best case state of affairs, a correct geomechanical mannequin can result in a profitable, optimized, worthwhile geothermal energy plant.

This visitor article written by TEVERRA highlights the important thing geomechanics purposes within the geothermal trade, together with wellbore stability, hydraulic fracturing, the particular challenges of superhot rock (SHR) geothermal programs, casing design, proppant choice, and thermal stress evaluation.

Wellbore Stability

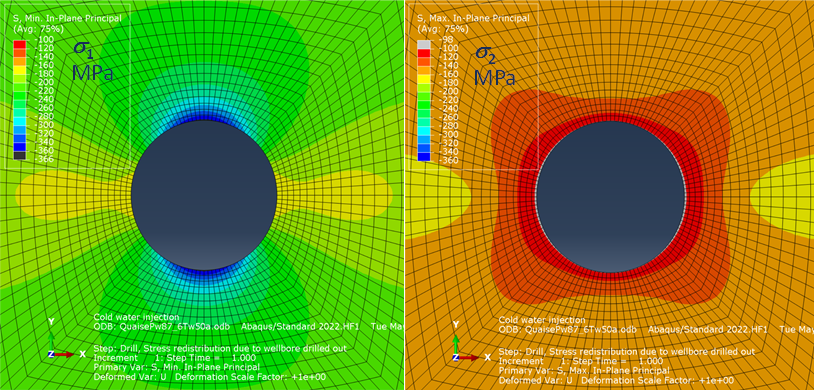

Wellbore stability is significant in efficiently creating and working geothermal power initiatives, notably in high-temperature and high-pressure environments. Excessive temperatures, excessive fluid pressures, and thermal stresses can considerably affect wellbore integrity.

Geomechanical evaluation is important to foretell and mitigate potential stability points, together with borehole collapse, borehole enlargement, and misplaced circulation, to make sure the long-term viability of geothermal wells. By optimizing drilling fluid design, casing, cementation packages, and wellbore completion methods, engineers can improve wellbore stability and maximize geothermal power’s financial and environmental advantages (Madyarov et al., 2021).

The determine above exhibits an instance of wellbore stability simulation mannequin outcomes: most principal stress (left) and minimal principal stress (proper) distributions across the wellbore with hydrostatic strain within the wellbore.

Hydraulic Fracturing

Hydraulic fracturing, a well-established approach within the oil and fuel trade, has been tailored to be used within the geothermal trade to improve reservoir permeability and enhance power extraction. By injecting high-pressure fluid into the subsurface formation, hydraulic fracturing creates advanced fracture networks that facilitate the circulation of geothermal fluids to the manufacturing effectively and environment friendly warmth extraction from the reservoir.

Nonetheless, the 20 years of hydraulic fracturing expertise within the oil and fuel trade exhibits that not all hydraulic fracturing designs are profitable. Geomechanical modeling is essential in optimizing hydraulic fracturing operations by predicting fracture propagation, minimizing induced seismicity, and maximizing reservoir productiveness. Cautious consideration of things resembling rock properties, in-situ stress state, and fluid injection parameters is important to make sure the success of hydraulic fracturing remedies in geothermal reservoirs (Porlles & Jabbari, 2022).

Superhot Rock (SHR) Geothermal Programs

Superhot Rock (SHR) geothermal programs supply a promising avenue for harnessing huge quantities of geothermal power from deep, high-temperature rock formations (Houde et al., 2021). These programs contain drilling deep wells into the Earth’s crust to entry scorching rock, fractured to create a reservoir. Water is injected into the fractures to extract warmth, which is then used to generate electrical energy.

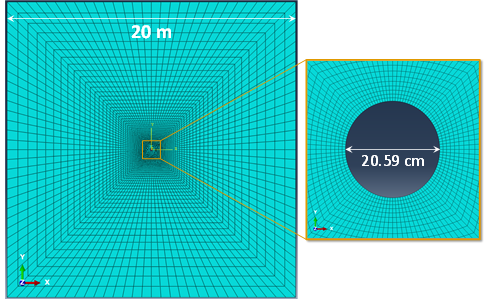

Whereas there may be important alternative, the intense temperature and strain situations related to SHR programs pose important technical challenges, together with wellbore stability, induced seismicity, and corrosion. Superior drilling applied sciences, hydraulic fracturing strategies, and strong wellbore design are important to beat these challenges, a lot of which can’t be examined till SHR drilling commences.

By understanding the geomechanical properties of the rock formations and simulating drilling and wellbore completion in SHR situations, the trade can progress in direction of optimizing the design and operation of SHR programs. As soon as profitable, SHR will unlock the large potential of this clear and sustainable power supply (Cladouhos & Callahan, 2024).

The determine above exhibits a geomechanical numerical mannequin (geometry and mesh) carried out to check wellbore stability of a hypothetical superhot rock wellbore.

Proppant Choice

Proppant choice within the geothermal trade includes selecting strong, granular supplies pumped into hydraulic fractures to take care of their permeability and improve fluid circulation.

In contrast to typical oil and fuel purposes, geothermal reservoirs usually expertise increased temperatures and pressures and publicity to corrosive fluids. These working situations are incompatible with many oil and fuel trade proppants; subsequently, proppants have to be fastidiously chosen to resist these harsh situations and keep their integrity over time.

Key components to contemplate in proppant choice embrace proppant lab evaluation utilizing geomechanics crushing take a look at, particle dimension distribution, power, thermal stability, chemical resistance, and cost-effectiveness. By optimizing proppant choice and placement, engineers can enhance the efficiency of geothermal reservoirs and maximize power extraction (Liu et al., 2023).

Thermal Stress Evaluation

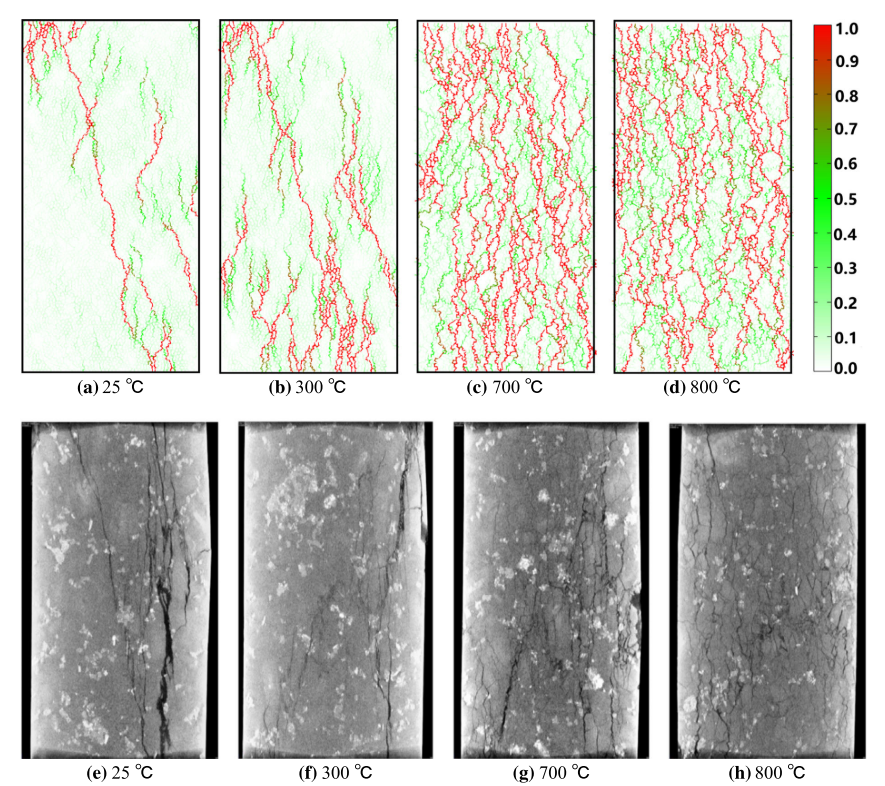

Thermal stress evaluation within the geothermal trade includes evaluating the affect of temperature gradients on the mechanical habits of rock formations and wellbore elements. Excessive-temperature variations between the recent reservoir rock and the cooler drilling fluid or injected water can induce important thermal stresses, resulting in potential points resembling wellbore instability, rock fracture, and lowered reservoir productiveness.

Geomechanical modeling strategies, together with finite component evaluation (FEA), simulate thermal stress distribution and assess its affect on wellbore integrity and reservoir efficiency. By understanding the thermal stress regime, engineers can optimize effectively design, casing choice, and manufacturing methods to mitigate the dangers related to thermal growth and contraction (Zhou et al., 2022). Geomechanics helps us to grasp crack patterns of the numerical mannequin are proven in determine beneath.

The Way forward for Geomechanics in Geothermal Vitality

The long run use and software of geomechanics in geothermal power may unlock immense useful resource potential, with technological developments and a rising emphasis on sustainable power sources. By integrating superior numerical modeling strategies, machine studying, and real-time monitoring, geomechanics will probably be essential in optimizing effectively design, enhancing drilling effectivity, and enhancing reservoir productiveness.

Because the trade continues to discover new power extraction approaches, resembling enhanced geothermal programs (EGS) and superhot rock (SHR) applied sciences, geomechanics will probably be important in addressing advanced challenges associated to wellbore stability, hydraulic fracturing, and reservoir administration (Jia et al., 2022).

By understanding the intricate interaction between geological, mechanical, and thermal processes, geomechanics will pave the best way for the sustainable growth and utilization of geothermal power.

References

Cladouhos, T. T., & Callahan, O. A. (2024). Warmth Extraction from SuperHot Rock-Expertise Improvement.

Houde, M., Woskov, P., Lee, J., & Oglesby, Ok. (2021). Unlocking Deep SuperHot Rock Sources By Millimeter Wave Drilling Expertise. GRC Transactions, 45.

Jia, Y., Tsang, C.-F., Hammar, A., & Niemi, A. (2022). Hydraulic stimulation methods in enhanced geothermal programs (EGS): a assessment. Geomechanics and Geophysics for Geo-Vitality and Geo-Sources, 8(6), 211. https://doi.org/10.1007/s40948-022-00516-w

Liu, S., Balushi, F., & Dahi, A. (2023). Conductive Proppants to Enhance Warmth Extraction. forty eighth Workshop on Geothermal Reservoir Engineering .

Madyarov, A., Porlles, J., Batir, J., & Soroush, H. (2021). Wellbore Stability Mannequin for an Injection Nicely in SuperHot Rock Drilled Utilizing MMW CO2 Innovation is Our Ardour. www.petrolern.com

Porlles, J. W., & Jabbari, H. (2022, June 26). Simulation-Based mostly Economical Modeling of Hydraulic Fracturing for Enhanced Geothermal System. All Days. https://doi.org/10.56952/ARMA-2022-2326

Zhou, Z., Mikada, H., Takekawa, J., & Xu, S. (2022). Numerical Simulation of Hydraulic Fracturing in Enhanced Geothermal Programs Contemplating Thermal Stress Cracks. Pure and Utilized Geophysics, 179(5), 1775–1804. https://doi.org/10.1007/s00024-022-02996-z