As energy vegetation confront getting old infrastructure, surging demand, and the sweeping modifications of speedy electrification, operations and upkeep (O&M) are being redefined to sort out unprecedented challenges and seize new alternatives.

In December 2025, the North American Electrical Reliability Company (NERC), the area’s designated electrical reliability group, issued a sobering evaluation of the facility sector’s outlook for the following decade. Greater than half of North America could also be prone to electrical energy shortages, it warned. The state of affairs is exacerbated by the accelerated retirements of 78 GW of getting old, fossil-fueled capability—with an extra 37 GW introduced however not but confirmed—and sluggish progress on new useful resource additions. Compounding the problem, energy demand is projected to soar by 15% over the following decade, pushed by speedy electrification, industrial progress, and the growing vitality wants of the data-driven financial system.

On this context, the area’s current fleet will play an outsized function, underscoring a task for his or her sound operations and upkeep (O&M). Nonetheless, NERC additionally flagged pressured outages as a crucial and rising concern for the facility sector, noting that unplanned outages brought on by gear failures, inadequate upkeep, and useful resource shortfalls pose important reliability dangers, most prominently throughout excessive climate occasions. With out strong O&M practices, these points might additional undermine the grid’s skill to satisfy rising demand, notably as winter peaks start to outpace summer season peaks. That has uncovered new vulnerabilities in useful resource adequacy planning, it mentioned.

However as specialists instructed POWER, the realm of O&M is itself quickly evolving to handle new complexities and expectations launched by the speedy transformation. As IHI Energy Options Director of Enterprise Improvement Doug Machon notes, O&M emerged traditionally as an easy enterprise operate managed internally by utilities working inside regulated monopolies. The realm started a shift within the Nineties, as competitors, launched by electrical energy deregulation, ushered in third-party O&M providers that supplied primary upkeep, compliance assist, and operational oversight. Immediately’s panorama provides a rising involvement from non-public fairness buyers, a decline in long-term energy buy agreements, and the rise of diversified vitality portfolios—together with renewables, distributed vitality assets (DERs), and hybrid configurations.

Not restricted to routine duties, fashionable O&M necessitates “a better degree of experience and innovation in plant operations,” says Machon. The numerous shift has catalyzed “the event of complete O&M methods designed to maximise effectivity, reliability, and profitability in an ever-changing vitality panorama.” Suppliers as we speak are anticipated to combine superior applied sciences, foster versatile plant cultures, and navigate stringent regulatory landscapes, he notes. Primarily, O&M as we speak capabilities each as a crucial lever for optimizing efficiency and enabling grid reliability in an more and more dynamic vitality surroundings, however it should additionally concurrently mitigate dangers and seize alternatives, he says.

Tackling New O&M Challenges

Based on Ricardo Guerrero, common supervisor for World O&M at GE Vernova, O&M development varies by area. “It’s totally different in each a part of the world, however I’d say the primary issue that affects O&M providers at this second is the penetration of renewables,” he says. Plunging prices for renewables have ushered in new operational calls for for conventional thermal energy vegetation, together with mixed cycle gasoline turbine (CCGT) energy vegetation, which had been traditionally designed as baseload workhorses. “Biking is an enormous concern,” Guerrero acknowledges. “Biking is related to how you will react, how you will accommodate your workforce, how you will accommodate your technique, your planning—the whole lot related to O&M providers—to be actually productive, handle price, and be environment friendly.”

Price pressures amid inflation and market demand additional compound these challenges. Energy sector O&M prices usually fall into mounted prices and variable prices. Mounted prices cowl constant bills like routine upkeep, employees salaries, and long-term gear contracts, whereas variable prices fluctuate based mostly on gasoline costs, materials wants, and surprising repairs. Over the previous 5 years, price fluctuations have hinged emphatically on rising materials prices for crucial assets comparable to metal, copper, and silicon, with explicit implications for getting old thermal energy vegetation that require frequent and expensive repairs.

|

|

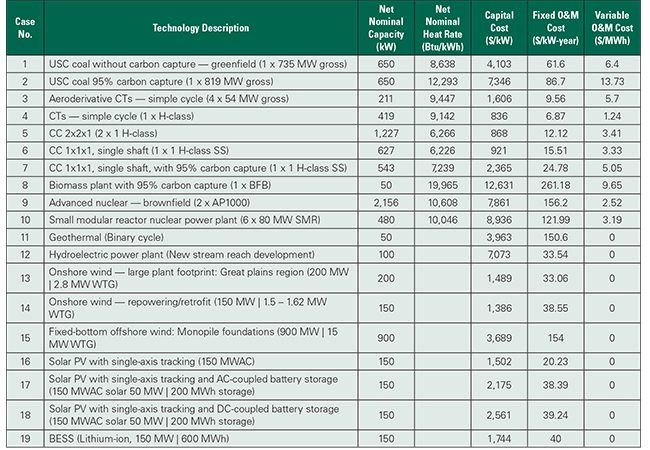

Desk 1. A December 2023 U.S. Vitality Data Administration (EIA) price and efficiency survey performed by Sargent & Lundy summarizes prices for many applied sciences, together with in a single day capital price info, mounted working and upkeep (O&M) prices, and variable non-fuel O&M prices. Notes: USC = ultrasupercritical; CTs = combustion generators; CC = mixed cycle; SS = single shaft; BFB = effervescent fluidized mattress; MWAC = megawatt alternating present; WTG = wind turbine generator; BESS = battery vitality storage system. Supply: EIA, Capital Price and Efficiency Attribute Estimates for Utility Scale Electrical Energy Producing Applied sciences, January 2025. |

Renewable O&M prices, whereas typically decrease than these of thermal energy vegetation, have been steadily reducing because of technological advances, economies of scale, and experience-driven efficiencies. Nonetheless, they continue to be delicate to materials value volatility and the rising demand for specialised upkeep providers. Offshore wind, particularly, faces larger O&M prices in comparison with onshore wind, pushed by logistical challenges, harsher environmental circumstances, and the necessity for specialised vessels and distant monitoring techniques. In the meantime, as a latest price and efficiency evaluation from Sargent & Lundy suggests, prices for superior applied sciences comparable to hydrogen retrofits and small modular reactors stay exorbitant (Desk 1). Whilst these applied sciences promise operational efficiencies and decarbonization advantages over time, excessive upfront investments and important ongoing O&M bills can pose severe feasibility challenges.

Enduring the Huge Realm of Coverage and Regulatory Uncertainties

Nonetheless, the present energy panorama is compelling extra firms to undertake new applied sciences and approaches. A major issue has been compliance with the evolving patchwork of presidency mandates, together with rules and incentives more and more centered on accelerated decarbonization. The U.S. Environmental Safety Company’s (EPA’s) April 2025–finalized Carbon Air pollution Requirements mandate carbon seize and sequestration (CCS) for current coal models and new baseload combustion generators, including to guidelines regulating nitrogen oxides, mercury, effluent, and coal ash. Regional decarbonization variations and overlapping state-level insurance policies are, in the meantime, creating further complexity, driving operators to undertake tailor-made methods to satisfy numerous compliance necessities.

Past emissions, rules now additionally emphasize grid stability and reliability, compelling typical turbines to supply ancillary providers comparable to quick frequency response and inertia. The necessity for resilience has additionally typically spurred mandates that require vegetation to bolster infrastructure to resist excessive warmth and chilly occasions, floods, and droughts. Cybersecurity is one other rising focus, with federal directives requiring energy vegetation to implement stricter digital protections and incident reporting protocols.

“You have to adapt to the market. If you happen to don’t react, in case you don’t change, in case you don’t alter your self to the brand new circumstances, you’re going to vanish,” notes GE Vernova’s Guerrero. GE Vernova’s method has been to arrange prospects for these transitions, together with tailor-made upkeep methods. “We have in mind the particular operational stresses brought on by renewables integration, guaranteeing that even older property adjust to regulatory thresholds whereas optimizing efficiency,” he explains.

Siemens Vitality, a world supplier of energy expertise, options, and providers, shares the same outlook. “Our O&M service is designed to handle and preserve numerous sorts of expertise infrastructure or gear. This method is very helpful in numerous and complicated operational settings comparable to carbon seize, the place a number of sorts of expertise coexist,” says Andrew Robson, Siemens Vitality’s technical professional for O&M Options.

Greatest Practices for Upkeep within the Evolving Energy WorldWhereas energy plant upkeep is a cornerstone of dependable energy technology, designing and sustaining an efficient program would require cautious consideration of recent challenges and methods. Engineers at infrastructure options agency Gannett Fleming provide some pointers. Perceive Your Property. Develop an in depth asset register to categorize and doc crucial property, together with electrical, mechanical, and civil infrastructure. Contain multidisciplinary specialists to make sure a complete understanding of upkeep wants. Develop a Upkeep Technique. Stability reactive, preventive, and predictive upkeep to handle fast wants whereas minimizing future dangers. Doc the rationale for every upkeep job based mostly on regulatory necessities, producer steerage, and danger evaluation. Leverage Know-how. Spend money on a computerized upkeep administration system (CMMS) like Maximo or SAP CMMS to streamline scheduling, documentation, and information evaluation, guaranteeing environment friendly useful resource allocation. Keep Agile. Keep away from static packages. Repeatedly assess and adapt upkeep methods to mirror developments in expertise, modifications in asset circumstances, and greatest practices. Prioritize Duties. Stop over-commitment by rating upkeep actions based mostly on danger to make sure crucial duties are executed successfully. Handle Challenges Holistically. Be cautious of knee-jerk reactions to failures and purpose for balanced options by way of root trigger evaluation and measured troubleshooting. Foster Collaboration. Streamline decision-making by clearly defining roles whereas incorporating enter from stakeholders to keep up agility in program updates. |

“Within the subsequent decade, Siemens Vitality will proceed to supply professional O&M providers to handle buyer reliability dangers, improve effectivity, and centralize abilities for constant and dependable service supported by data-driven digital applied sciences,” Robson provides. Whereas the necessity to decarbonize typical energy technology impacts all utilities and isn’t particular to O&M, the corporate’s providers “be sure that these applied sciences function reliably and effectively, contributing on to assembly decarbonization objectives,” he explains. Moreover, he underscores broader sustainability advantages, notably by way of the usage of a world community of distant operations and management facilities. “Particularly throughout COVID, it grew to become clear that it isn’t all the time essential to fly specialists world wide, however that so much may be executed remotely,” he says (see sidebar “Greatest Practices for Upkeep within the Evolving Energy World”).

Fixing the Workforce Puzzle

For now, specialists agree probably the most pressing problem going through the facility sector is the scarcity of expert personnel. “O&M is all about individuals,” says Guerrero. “Individuals are likely to imagine that sooner or later, energy vegetation will probably be operated utterly by robots, however we’re actually far-off from that.” A key concern is that the workforce, historically the spine of energy plant operations, is getting old, and with that comes the lack of a long time of invaluable expertise. “On the similar time, we’re discovering it more and more tough to draw youthful expertise, who are sometimes drawn to tech-savvy industries like software program and synthetic intelligence [AI] moderately than conventional fields like ours. It’s an issue we can not afford to disregard as a result of, with out expert employees, even probably the most superior vegetation gained’t operate,” he says. To deal with these challenges, Guerrero explains that GE Vernova has developed structured knowledge-capture techniques, together with detailed playbooks created throughout contract mobilizations. “These are complete guides that guarantee when skilled workforce members retire or transfer on, their experience doesn’t depart with them,” he says.

On the similar time, GE Vernova, pushed by its “lean” enterprise philosophy, has already begun transitioning from conventional reliability-based upkeep approaches to extra proactive, data-driven design-making enabled by AI and analytics. Guerrero mentioned the corporate has developed autonomous robotic expertise able to conducting inspections and figuring out points that human employees might miss. Demonstrating these applied sciences carries operational advantages, however a key intent is to rework the notion of O&M, positioning it as modern, future-focused, and dynamic—attributes that might be engaging to a youthful workforce, he says.

|

|

1. Accomplished in early 2025, the Leipheim Energy Plant in Bavaria, Germany, is a cutting-edge gasoline turbine facility developed by Siemens Vitality and German vitality large LEAG to bolster grid stability throughout renewable vitality shortfalls. The plant, able to ramping up remotely inside half-hour to ship 300 MW of energy, is operated completely from Siemens Vitality’s ISO-certified Distant O&M Help Middle in Erlangen. Courtesy: Stefan Hobmaier/Siemens Vitality |

Robson echoes Guerrero’s considerations. “Even utilities with intensive expertise in energy plant operation and upkeep at the moment are looking for our O&M experience as a result of expert workforce scarcity,” he notes. Siemens Vitality’s method has been to double down on expertise. “Distant providers are key to sustaining dependable operation and environment friendly upkeep,” says Robson, citing Siemens Vitality’s 72-hour unmanned operation of the 300-MW Leipheim Energy Plant in Germany (Determine 1). “Our distant monitoring facilities deal with routine monitoring and information evaluation, liberating up specialists for duties that can’t but be totally automated.”

Based on Emily Obenauer, international director of Product Advertising and marketing at SiteTracker—a software-as-a-service platform that gives end-to-end asset lifecycle administration—rising instruments are additionally set to play a transformative function in streamlining O&M operations with tangible workforce advantages. “Instruments like ours are additionally proven to extend the satisfaction and improve the effectiveness of these employees out within the subject as a result of we’re getting so clear on what must be executed and validating that that work has been executed appropriately the primary time round,” she mentioned.

Shoring Up Provide Chains

Whereas workforce challenges have lengthy troubled the sector, newer international provide disruptions are posing new considerations, prompting firms to reassess the resilience of their O&M operations. Siemens Vitality’s Robson notes that, whereas short-term bottlenecks for elements and consumables stay a priority, “The scarcity of individuals is, so to talk, the most important bottleneck within the provide chain,” he says. He explains that almost all authentic gear producers (OEMs) proactively method provide chain challenges to mitigate dangers, leveraging international networks for flexibility. “We will entry inventory that was initially deliberate for different initiatives in the long run. Moreover, shut monitoring permits for the identification of required elements at an early stage as a part of predictive upkeep,” he says.

|

2. To bolster its provide chain and put together for growing demand for its heavy-duty gasoline generators and upgrades globally, GE Vernova moved in November 2025 to amass Woodward Inc.’s combustion elements enterprise in Greenville, South Carolina. This picture reveals a 7HA.03 gasoline turbine at GE Vernova’s personal facility in Greenville, the place it manufactures and assessments gasoline generators to supply international engineering assist and different actions. Courtesy: GE Vernova |

GE Vernova’s technique is comparable, entailing a proactive, collaborative method with its prospects (Determine 2). The corporate intently screens its prospects’ gear and offers advance warning of potential failures. As well as, Guerrero says it helps prospects pre-position crucial spare elements to attenuate downtime within the occasion of a problem. For instance, when GE Vernova recognized that the turbines at a 20-year-old energy plant in Taiwan had been nearing the top of their life, it suggested the client to buy a spare stator and rotor upfront. Two years later, the rotor failed, however as a result of the spare half was already on-site, GE Vernova was in a position to rapidly substitute the rotor, getting the client again on-line in simply seven days, he says.

The Rise of Third-Occasion O&M Companies

In one other essential development, given fashionable complexities and evolving dangers within the energy sector, many utilities and energy firms are more and more turning to value-driven partnerships, typically by way of third-party O&M service contracts. These partnerships embody mission administration, strong coaching packages, detailed plant assessments, and the adoption of tailor-made greatest practices to optimize operations. Many are designed to leverage economies of scale and superior distant operations, offering utilities with price efficiencies and enhanced reliability in managing numerous vitality property.

“For a lot of plant homeowners, O&M is now not a core focus,” Guerrero explains. “Their precedence is on producing and promoting vitality, which opens the door for third-party suppliers like us to step in with specialised experience. Nevertheless it’s not nearly taking on operations—it’s about including worth. By leveraging performance-based contracts and superior applied sciences, we give attention to aligning our providers with plant homeowners’ objectives for reliability, effectivity, and profitability.” Guerrero notes that performance-based contracts are more and more turning into a defining function of third-party O&M providers as a result of they play a pivotal function in aligning incentives with plant reliability, availability, and effectivity. The contracts guarantee accountability by incorporating measurable metrics, comparable to efficiency ensures, and sometimes embrace penalties for underperformance in addition to rewards for exceeding targets. “This mannequin ensures that everybody is targeted on the identical aim: maximizing the plant’s efficiency,” he says.

World renewable vitality developer Invenergy— an organization recognized for its intensive portfolio of wind, photo voltaic, and storage initiatives—additionally highlighted the worth proposition. The corporate says it approaches O&M providers with an “proprietor’s mindset,” a philosophy that ensures top-tier upkeep practices and builds belief inside their communities. “Along with prioritizing security, Invenergy Companies’ different O&M pillars ship advantages to prospects by way of innovation, flexibility, and value financial savings,” it says.

O&M’s Future: Tech and Sustainability

Based on specialists, the way forward for O&M within the energy sector will probably be formed by two transformative forces: technological innovation and the worldwide push for sustainability. Already, as energy technology grows extra advanced, fashionable O&M practices are more and more integrating cutting-edge applied sciences like predictive analytics, autonomous techniques, and upkeep methods. “The way forward for operations and upkeep will closely rely on integrating AI with digital instruments to investigate information in real-time. This enables us to foretell points earlier than they happen, saving prices and enhancing asset efficiency throughout the board,” says Guerrero.

Obenauer echoes this level. “We all know that the long run lies in digital transformation, and AI is a serious focus. By making use of AI to fieldwork and O&M processes, we’re already testing the right way to improve effectivity and reliability whereas aligning with the workforce and business wants.” AI-driven options additionally promise to unlock new alternatives in lifecycle administration, she notes. “By centralizing asset information, firms can use AI to optimize useful resource allocation and give attention to long-term asset well being whereas navigating advanced operational challenges.”

|

|

3. Operational since June 2023, the Kela PV Plant Part 1, positioned in Sichuan Province, China, stands as one of many world’s largest hydro-solar hybrid energy vegetation, combining 1 GW of photo voltaic capability with the three GW Lianghekou Hydropower Plant. The positioning exemplifies superior O&M practices in a difficult surroundings. Provided that it’s located at an altitude of 4,600 meters, the plant endures excessive chilly and excessive winds. Utilizing a wise O&M platform with options like distant monitoring, automated fault detection, and real-time diagnostics, the plant minimizes handbook intervention and ensures reliability. Courtesy: Huawei |

However, sustainability will assist the final cost towards cleaner vitality sources, comparable to accommodating new applied sciences and hybrid configurations (Determine 3). Corporations are exploring the right way to combine rising options comparable to hydrogen retrofits, thermal vitality storage, and batteries into energy vegetation, all whereas retaining prices low, sustaining reliability, and minimizing environmental affect.

As Guerrero stresses, a key takeaway is that O&M will should be versatile and responsive moderately than inflexible. “You may navigate the ocean as a cruise ship, otherwise you could be a bike on the seashore transferring fast, and that’s the thought, that’s what we’re doing,” he explains. In the end, proactivity will probably be vital for nimble adaptation to maintain tempo with the altering panorama, he says.

—Sonal Patel is a POWER senior editor (@sonalcpatel, @POWERmagazine).