Excessive temperature and climate occasions have grow to be extra prevalent up to now decade. The December 2022 Christmas freeze within the southeast U.S. noticed many areas experiencing single-digit temperatures. The February 2021 Texas freeze noticed temperatures in Dallas attain as little as –2F. In the meantime, the January–February 2019 Midwest Arctic Polar Vortex noticed temperatures plunge as little as –30F.

Every of those occasions considerably strained electrical infrastructure inflicting inoperable utility tools and energy outages. Inside the U.S., lots of the regulatory companies are mandating that useful resource entities determine cold-weather-critical tools, develop freeze safety measures for this tools, and doc the minimal ambient dry-bulb temperatures that the useful resource can reliably function to. For these mandates, sometimes, the minimal working temperature could be based mostly on historic working knowledge, tools ranking, or engineering evaluation. Much more just lately, some regulatory companies have put into place necessities addressing wind velocity and wind chill.

Chilly climate procedures and tools adjustments commonest within the colder climates are making their method throughout the U.S. Mills must be ready for chilly climate to keep away from misplaced producing potential, which may translate into misplaced income, fines, and tools injury.

Water and Wind

Water is a significant freeze danger, and any tools that makes use of water must be protected. Programs and tools not wanted throughout chilly climate operation ought to be faraway from service and the water drained to make sure the tools shouldn’t be broken throughout a freeze occasion. Water wash programs, inlet chillers, or moist compression programs are examples of kit that may be faraway from service and drained if climate forecasts point out chilly climate approaching; it will enable winterization efforts to deal with gadgets wanted for plant operation throughout a chilly climate occasion.

Some tools utilizing water might want to stay obtainable, comparable to NOx water programs, boilers, sensing traces, and warmth exchangers. A standard method to defend tools is insulated warmth tracing or the addition of a freeze inhibitor (glycol) if the water is a part of a closed-loop warmth alternate system. Some programs could be drained after which refilled previous to the unit coming on-line.

Wind by itself can not trigger freezing. The ambient temperature should be under freezing for water to freeze. At temperatures under freezing, wind can quickly improve the freeze charge by growing convection, or the speed at which warmth is faraway from a pipe or different water supply. Wind results could be negated by correct wind breaks and/or insulation.

Tools Issues

Gasoline Programs. Pure fuel is really useful to be maintained above 40F for correct gas nozzle operation to reduce the condensation of hydrocarbons and moisture in fuel. Liquid fuels may have their very own minimal temperature that must be maintained. Gasoline traces are at all times buried under the freeze line, which helps keep fuel temperatures above freezing. It’s good apply to insulate the principle provide valve, and moisture filter drain traces ought to be protected to keep away from freezing. Heaters could also be wanted for liquid fuels with minimal temperature necessities.

Gasoline Turbine Inlet and Bellmouth. Inlet icing or snow accumulation could cause extreme strain drops, inflicting unit derate or journey. To keep away from this, well-sized hoods ought to be used to guard the inlet from extreme accumulation. Coalescing-type filters, designed to take away and acquire moisture, ought to be eliminated earlier than winter.

Compressor bellmouth icing can happen when inlet air is chilly and humid, even when the ambient temperature is above freezing. Isentropic acceleration of air can cut back the air temperature by as a lot as 4F. A viewport could be added to look at the bellmouth (Determine 1). If icing happens, or a historical past of icing is thought, inlet air heating could be added to keep away from international object injury from ice ingestion.

Generators and Generator. It is suggested to have a heater in every turbine and generator enclosure, devoted to making sure important tools contained in the enclosure is protected. If the turbine and generator are positioned inside a constructing, the constructing ought to incorporate a number of heaters to keep up temperature contained in the constructing. Enclosure or constructing, doorways and vents ought to be closed to reduce chilly air intrusion. Throughout excessive chilly occasions, air getting into from an open door or vent can overwhelm the flexibility of a heater to keep up enclosure temperature.

It’s good apply to position generators on a turning gear at sub-freezing temperatures. This may also hold lube oil flowing. Extra safety could also be required for bleed and purge valves, tools configuration relying.

Mills sometimes have inner heaters to make sure moisture ranges are stored low. These inner heaters for moisture management don’t negate the necessity for a separate compartment or constructing heater, particularly throughout excessive chilly climate occasions. It’s famous that steam generators will not be delicate to adjustments in ambient temperatures.

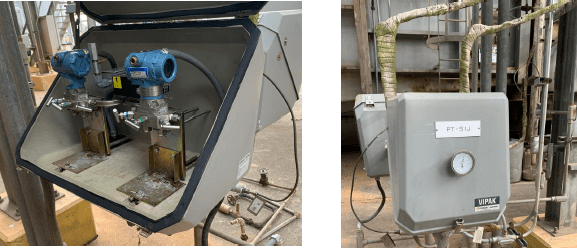

Valves, Instrumentation, Plant Air, and Pumps. Failure of small valves or drains could cause large issues. All important valves ought to be insulated, and strain, movement, and temperature transmitters ought to be stored in protecting bins with a warmth supply (Determine 2). Sensing traces using water ought to be warmth traced and insulated.

Plant air compressor drains ought to be stored from freezing and the air dryer ought to be able to dropping the dew level by a minimal of 18F. Most dryers are succesful properly past this. Valves that go undried air, comparable to compressor bleed valves, are in danger from freezing and ought to be protected with warmth and insulation. Relying on valve place, windbreaks could also be obligatory.

Water pumps which are important to plant operate should be protected. Submersible pumps that sit in deep wells are sometimes protected because the water surrounding them doesn’t freeze. In-line pumps, comparable to boiler feedwater pumps, should be protected by a warmth supply or heat water recirculation and wind breaks.

Lube Oil Programs. It is suggested to have further immersion heaters obtainable in case of a failure throughout a chilly climate occasion. It’s good apply to test the temperature of lube oil tanks throughout web site rounds, particularly at websites configured with uncovered lube oil skids. Insulation of uncovered lube oil traces could also be obligatory if websites are liable to experiencing excessive winds. Lube oil programs on uncovered skids might require wind breaks or probably an enclosure with a heater.

Climate Planning

Winterization Strategies. All obligatory water programs must be protected with warmth hint and insulation (Determine 3), recirculation from a heat water supply, and any water remedy buildings ought to be heated. Cooling programs, wherever doable, ought to make the most of a glycol-water combination and all pointless water programs ought to be shut off and drained.

Crucial tools ought to be shielded from the results of chilly wind. Typical safety strategies are warmth hint and insulation, windbreaks, and/or non permanent enclosures with heaters.

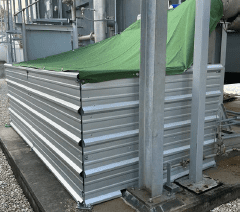

Windbreaks ought to account for prevailing wind route. Observe that windbreaks must be sturdy. Tarps tied round tools is not going to be as sturdy as scaffolding wrapped in plastic or steel frames with steel partitions (Determine 4). Satisfactory wind safety will decrease the impact of convective warmth switch.

Backup tools, comparable to turbines or air compressors, could also be applicable if the power has a historical past of particular tools failure throughout chilly climate occasions. Further winterization tools ought to be stored onsite. This could embody tarps, heaters (Determine 5), extension cords, and gadgets to deal with emergent points.

Chilly Climate Working Process. Websites ought to keep chilly climate plans applicable for the plant location. The intent of a written process is to make sure a plan is in place and gives route for easy methods to hold items working throughout chilly climate occasions. Updates to the process are a important a part of danger mitigation as a result of tools failure modes can range with age; climate patterns can shift; and plant operational modes, configurations, and private can change. What labored up to now is not going to essentially be enough sooner or later. A very good chilly climate plan ought to embody the next:

- Listing of cold-weather-critical tools.

- Listing of weatherization provides and tools.

- Accountable events and speak to info.

- Staffing necessities.

- Plan implementation particulars, together with standards (calendar date vs. temperature particular).

- Checklists.

- Preparation.

- In-action.

- Put up-action/corrective-action.

- Revision management.

- Documentation of historic minimal and most temperatures.

- Coaching necessities.

Abstract

Chilly climate occasions will proceed to occur. Preparation and planning are important for vegetation to stay operational throughout occasions.

To satisfy our clients’ requests to maximise plant availability throughout chilly climate operation, TG Advisors has developed a “Climate Readiness Evaluation” that accomplishes three objectives by way of knowledge evaluation, assessment of plant upkeep data, engineering calculations, and professional expertise. The evaluation:

- Addresses regulatory requests (sometimes minimal ambient temperature functionality and/or wind chill functionality).

- Identifies tools limitations and alternatives for improved robustness.

- Opinions a plant’s climate preparation and motion plan and gives suggestions for enchancment.

TG Advisors’ course of features a plant walkdown and interview with key personnel to assessment tools situation and plant configuration and to determine site-specific wants. Please attain out to us with any questions or discuss to us about how we may help your web site maximize availability in the course of the chilly climate season.

—David Butz ([email protected]) is a senior consulting engineer, and Jason Neville is the engineering supervisor and a marketing consultant, each with TG Advisors, an ENTRUST Options Group firm. To learn to put together for warm climate, learn “Sizzling Climate: Learn how to Preserve Energy Plant Readiness and Dependable Operation.”