Austal USA Superior Applied sciences is working with the US Navy on technical options that can energy the next-gen of navy belongings. Don Hairston not too long ago took the helm of the AAT staff, and discusses how additive manufacturing and synthetic intelligence are powering the way forward for naval asset design, development and lifecycle upkeep.

Don, what particularly attracted you to the place as GM of Austal USA Superior Applied sciences?

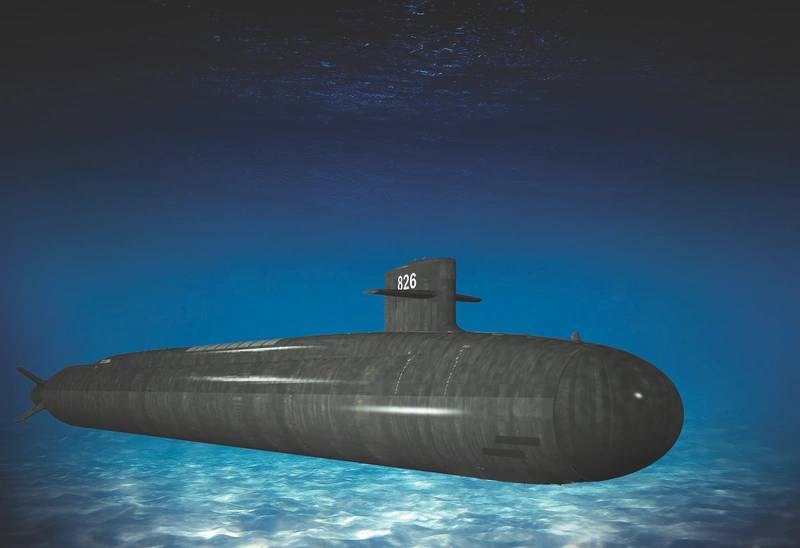

I appreciated Austal USA as an up-and-comer; it presents great development alternatives. I additionally just like the superior expertise facet, particularly within the additive manufacturing (AM) area. Our mission in AM is to help the submarine industrial base in attaining the ‘one plus two’ objective … that’s development of 1 Columbia and two Virginia class submarines per a yr. The one approach we’re going succeed is thru automation, a giant a part of which is additive manufacturing. It was interesting to me coming into Austal USA main the Superior Know-how division, with a transparent deal with the Navy’s Additive Manufacturing Middle of Excellence in Danville, Virginia.

What are the important thing expertise drivers of your major buyer – the US Navy?

If we have a look at the submarine industrial base, there’s a rising want for individuals, processes and automation, to help the rising scope of additive manufacturing; our partnership with the Institute for Superior Studying and Analysis, additionally positioned in Danville, is a key factor for attaining the Navy’s one plus two requirement. Basically, you want individuals, and the Institute brings a pipeline of highly-skilled, educated operators in expertise essential to manufacturing submarines. We’ve got the whole lot from coaching during manufacturing and half supply co-located in Danville. That end-to-end functionality is what we’re driving to help the US Navy with specific emphasis on the submarine industrial base.

Within the context of AAT is doing for the Navy, what particularly does additive manufacturing imply?

At this time, the submarine industrial base depends on forging and casting homes to offer mission-critical elements, and sadly the present industrial base can’t help the one plus two cadence. As a substitute of rising the casting and forging industrial base footprint, we’re trying to increase and evolve that footprint by way of additive manufacturing. We’re leveraging cutting-edge modalities for additive manufacturing corresponding to laser powder mattress fusion, direct vitality deposition, friction stir processing and chilly spray. Coupled with the completely different modalities are varied alloy varieties; our plan is to mix as much as six completely different alloy varieties with the suitable modality to make sure that the correct half is constructed with the correct course of and the correct alloy. Primarily, we’re constructing the correct “recipes”, within the type of Technical Information Packages (TDPs), that prescribe an alloy sort and AM modality for the commercial provide base to scale manufacturing of AM elements. The AM Middle of Excellence is assembling the TDPs for dissemination to a community of additive producers, and different machines throughout the community that we’re establishing, to inject AM elements into the availability stream as alternate options to forgings and the castings. We’re not going away from forging and castings; we’re supplementing manufacturing capability.

Low cost uneven techniques are proving efficient towards a lot bigger, rather more costly and highly effective belongings. How are these tendencies impacting your work?

Austal USA has expanded its focus space to handle these tendencies – I consider that giant numbers of autonomous drones are the correct reply. As an example, we’re supporting L3Harris in constructing out the GHOST fleet, and we’re taking part within the Overlord program, presently constructing vessel #3 and the sooner vessels on which Austal’s automated equipment management techniques have been put in. Additionally, by way of Saildrone, Austal USA is constructing a 65-foot ISR and ocean mapping vessel known as Surveyor. Austal USA has additionally built-in layers of autonomous techniques on EPF-13 with success; these built-in layers embody automated equipment controls, L3Harris’s ASView, in addition to Basic Dynamics wave predictive capabilities. Tying these capabilities collectively on an built-in spine on EPF-13 successfully demonstrated the opportunity of an autonomous massive floor vessel to the US Navy. Austal can be pursuing a primary contract to construct the Giant Unmanned Floor Vessels (LUSV).

Drones and autonomy are a key piece of the US Navy’s future necessities, and Austal USA Superior Applied sciences is poised to carry additive manufacturing capabilities to the fast manufacturing and deployment of unmanned techniques to satisfy that want. We should to be able to scale up utilizing additive manufacturing manufacturing capabilities for small and medium vessels. Sooner or later, we will probably be ready to print small sized vessels, however presently our focus is the submarine industrial base.

What tech do you see within the formative stage that can decide the scale and form of the US Navy fleet of tomorrow?

Information analytics and AI are pivotal as we construct Navy’s future fleet. They provide the chance to have fleets of unmanned vessels of all dimensions and shapes, within the air, on land, and on the floor and underwater. The flexibility to help belongings from a predictive modeling perspective and a product lifecycle administration standpoint is essential; end-to-end performance-based logistics is feasible by way of the elemental understanding of system engineering and the system engineering mannequin, working in live performance with knowledge analytics and AI. It’s one factor to have a fleet, it’s one other factor to help it, and thru knowledge analytics and AI, I consider that’s going to be a recreation changer.

What are your goals within the coming 12 to 24 months?

The precedence is reworking the submarine industrial base with AM and growing a extremely expert workforce to help it. Our near-term objective is to construct out the community of suppliers, not solely on the Middle of Excellence, however rising our companions as properly. We’re activating suppliers by guiding them by way of Navy AM technical necessities, flowing down high quality requirements, and serving to them to ascertain strong AM capabilities. Our AM base is being primed to print good elements utilizing TDP recipes which are prepared for set up.

We’re investigating course of automation to enhance the effectivity of provider activation to extra quickly increase our community. Proper now, we’re producing tens of TDPs per quarter, however our final objective is to provide a whole lot of TDPs per quarter. We wish to scale from tens of elements to hundreds of elements per yr. This exponential development is critical to help that ‘one plus two’ initiative from a manufacturing standpoint. Different essential focus areas embody constructing the coaching pipeline, and automating your entire provide chain course of to help this development mindset.

Watch the total interview with Don Hairston on Maritime Reporter TV: