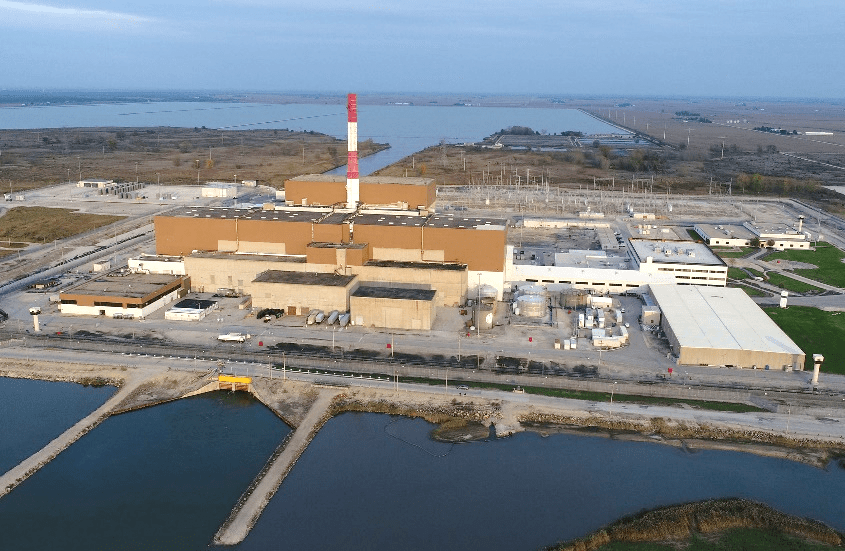

Constellation Power will use a portion of newly introduced federal funding for the Midwest Hydrogen Hub (MachH2) to construct “the world’s largest nuclear-powered clear hydrogen facility” at its 2.3-GW LaSalle Clear Power Heart in Illinois.

The corporate on Oct. 16 mentioned it plans to leverage a $1 billion award introduced by the Division of Power (DOE) final week for MachH2—a large hydrogen hub that can combine initiatives in a number of Midwestern states—to supply an estimated 33,450 tons of fresh hydrogen every year at LaSalle, its large nuclear plant in Marseilles, Illinois. The hydrogen hub award, allotted within the November 2021–enacted Infrastructure Funding and Jobs Act, might “offset” LaSalle’s estimated $900 million prices for the nuclear hydrogen challenge, it mentioned.

The challenge’s timeframe, nevertheless, is unclear and could also be decided because the MachH2 alliance completes negotiations with DOE to finalize particulars and situations of the award, the corporate urged. As POWER has reported, the DOE expects its chosen hubs will likely be executed over a broad timeframe of about 8 to 12 years or sooner, relying on their dimension and complexity.

Constellation on Monday additionally urged the challenge could also be contingent on federal steerage from the U.S. Treasury that might make clear how hydrogen suppliers will qualify for tax credit of as a lot as $3/kilogram (kg), as outlined within the August 2022–enacted Inflation Discount Act. “Within the months main as much as this choice, Constellation, organized labor companions and enterprise leaders have urged the administration to supply vital steerage implementing Congress’ intention to permit hydrogen manufacturing utilizing carbon-free energy from present nuclear stations to earn tax credit contained within the Inflation Discount Act,” famous Joe Dominguez, Constellation president and CEO, on Monday. “With out these credit, initiatives like this one won’t go ahead.”

Dominguez, nevertheless, urged the DOE’s hydrogen hub awards unveiled final week mark a optimistic step. “At this time’s award is proof optimistic that DOE and the administration need present nuclear power to play a significant position in jumpstarting home hydrogen manufacturing and we sit up for closing Treasury Division steerage,” he mentioned.

Banking on 9 Mile Level’s Pioneering Nuclear Hydrogen Demonstration

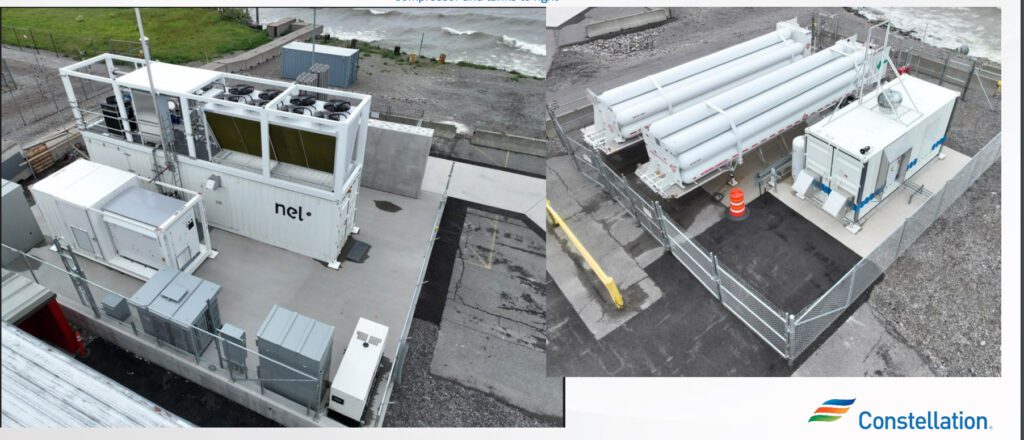

Constellation, which is presently the most important producer of nuclear power within the U.S., on Monday famous it plans to “make use of classes realized” from Constellation’s 1-MW nuclear hydrogen demonstration at its 1.9-GW 9 Mile Level nuclear plant in Oswego, New York, to construct the LaSalle facility. The pilot demonstration started producing 531 kilograms (kg) per day of hydrogen in March utilizing a Hydrogen Technology System proton change membrane (PEM) electrolyzer, which was manufactured by Nel Hydrogen.

The demonstration, the primary of a number of important efforts across the U.S. to look at how nuclear hydrogen will be feasibly built-in into the broader power market, formally kicked off in July 2021. Together with in search of to confirm steady-state in-house hydrogen manufacturing, a key challenge goal has been to simulate a scaled-up operation of a bigger electrolyzer’s participation in energy markets.

Price forecasts for the 9 Mile Level pilot demonstration hover at about $14.4 million, Constellation has mentioned. The pilot leverages a $5.8 million DOE award that supported the development and set up of its low-temperature electrolysis system. A separate $12.5 million award from the New York State Power Analysis and Improvement Authority (NYSERDA) bolsters a “follow-on” challenge to put in a gas cell on the facility. That challenge, anticipated to begin up in 2025, might permit the system to make use of the surplus capability from its electrolyzer to retailer long-duration power and put it again onto the grid throughout peak demand situations.

The pilot, notably, additionally obtained technical backing from the Idaho Nationwide Laboratory and Argonne Nationwide Laboratory, which developed a front-end controller and oversaw the dynamic operation of its prototype electrolyzer. The Nationwide Renewable Power Laboratory offered evaluation for scaled-up hydrogen manufacturing and hydrogen market evaluation.

Throughout a July 2023 DOE-hosted webinar, 9 Mile Level Pilot Demonstration Mission Supervisor Robert Beaumont mentioned the challenge has to this point achieved key milestones “slightly below finances.” The challenge, he mentioned, was initially conceived to bolster its backside line by producing its personal hydrogen for in-house consumption. The pilot, nevertheless, additionally promised to show the “dynamic operation” of its electrolyzer, enabling distant management of the electrolyzer to ramp it up and down in response to grid situations.

9 Mile Level makes use of “a good quantity” of hydrogen onsite for its boiling water reactors, most of which was beforehand “trucked in” from the Philadelphia space, Beaumont famous. “We add hydrogen into the nuclear core, and that helps alleviate any oxygen contained in the core space and reduces corrosion contained in the core,” he mentioned. By making its personal hydrogen, the nuclear plant successfully offers an “financial provide of in-house hydrogen for consumption,” he mentioned.

At the moment, the plant makes use of 15% of its produced hydrogen—of 531 kg/day—“constantly to help the plant,” he famous. “The bigger electrolyzer provides us the flexibility to function dynamically and go to charging,” which includes filling two containerized tube trailers. “If I cost for 4 hours a day, then I can flip the system off and run from the trailers for the remaining 20 hours a day,” he mentioned.

The native output of the electrolyzer is “someplace round 400 PSI, plus or minus 30,” Beaumont famous. “Our hydrogen system likes to make use of this strain at about 250 kilos per sq. inch, and that’s so the electrolyzer can feed instantly as wanted simply by going by a strain discount system,” he added. “Once we go to storage, we compress from that 400 kilos as much as about 2,200 kilos. And that’s based mostly on the storage that we’re allowed to have as a part of our blast calculation for the hydrogen storage trailers and their location.”

Unveiling Actual-World Hurdles

Nonetheless, growth of the first-of-its-kind challenge entailed a number of issues, akin to figuring out standards for the perfect website to position the electrolyzer. “The facility comes off the generator at about 25,000 V, and it then goes by a transformer that provides energy to the nuclear energy station itself,” stepped all the way down to about 13,800 V, Beaumont mentioned. “We hook the electrolyzer as much as that 13,800-V bus, and we ran the cable throughout the positioning to go to the electrolyzer.” In complete, 9 Mile makes use of 1.25 MW for the electrolyzer stack to supply hydrogen at full output, and one other 250 kW for the electrolyzer’s auxiliary pumps, motors, compressor motors, and cooling techniques.

The crew’s early growth work additionally concerned pinning down regulatory limitations, together with from the Nuclear Regulatory Fee (NRC), the North American Reliability Corp., the New York Impartial System Operator, New York state regulators, and the Environmental Safety Company. “As a part of these choices, we selected to place the system exterior our protected space and away from any of our security techniques,” he mentioned.

The challenge’s 100% site-specific closing engineering design was wrapped up in February 2022, and the nationwide laboratories accomplished an financial feasibility evaluation for the scale-up on the finish of 2022. “We began full operation on March 7 of this yr, and we’ve been supplying the plant since then,” Beaumont mentioned.

“We’ve proven that the compressor can work off-peak and fill on the interim storage tanks, run off the storage tanks throughout peak hundreds, after which proceed to cost throughout off-peak occasions,” he famous. “We’ve additionally proven that we are able to function constantly with low energy utilization constantly, and we’re nonetheless evaluating which goes to be higher for the operation of the plant.”

However the pilot additionally gleaned key learnings. It led, for instance, to a refined compressor manufacturing facility acceptance testing, and the event of specialised valve seal supplies that might stand as much as freezing temperature situations in upstate New York, he mentioned. The challenge was additionally compounded by provide chain disruptions, together with these stemming from the COVID-19 pandemic and the battle in Ukraine, which affected European elements.

In response to Beaumont, the challenge continues to discover nuclear hydrogen’s wider prospects for system integration. “In future work, we’ll proceed to show the dynamic operation on the positioning and give you the optimum, balancing each the economics and the operational situations to find out how we’re going to function the system long-term,” he mentioned.

—Sonal Patel is a POWER senior affiliate editor (@sonalcpatel, @POWERmagazine).