There are lots of methods to boost energy grid and energy plant reliability, together with the implementation of superior management methods, proactive upkeep applications, and trendy applied sciences for early detection of potential points. Learn the way utilities can leverage new software program, automation, and predictive applied sciences to enhance operational efficiency whereas managing growing old infrastructure.

Amongst these speaking with POWER about reliability enhancements for the ability grid was James Nyenhuis, plant efficiency guide for Emerson. Nyenhuis supplied POWER with perception in regards to the work being carried out to assist a dependable provide of electrical energy, from the ability plant to the sting of the grid.

POWER:What are some enhancements that may be made to an electrical energy transmission and distribution system and/or an influence plant (thermal or renewable) to enhance its reliability?

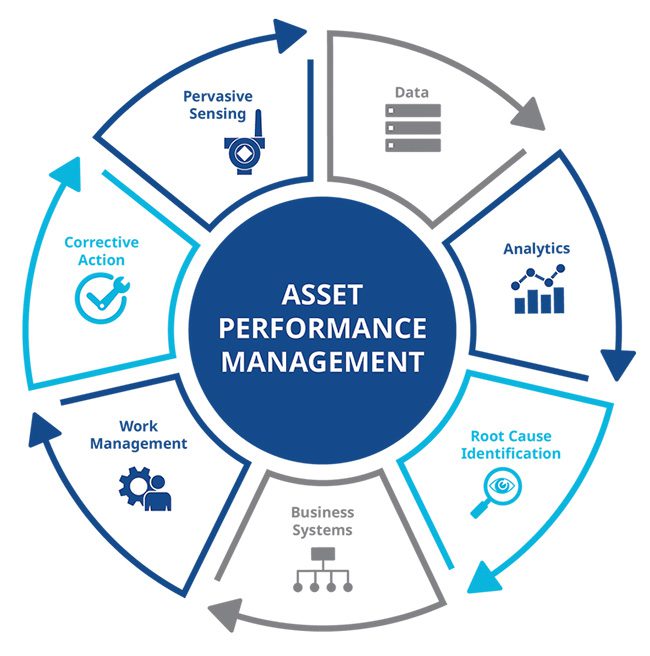

Nyenhuis: Reliability has at all times been a key focus for the ability technology business, however what we see altering considerably in at the moment’s setting is a continued evolution of applied sciences, which offer environment friendly means to course of extra data nearer to its supply and supply earlier detection of evolving reliability dangers [Figure 1]. One of many first enhancements that involves thoughts, which might enhance reliability of the ability producing facility, is to make sure that operations groups are supported by a well-designed alarm and alert administration course of.

|

|

1. Complete asset efficiency administration focuses on crucial belongings that require speedy consideration to enhance efficiency via elevated manufacturing and decreased upkeep prices. Courtesy: Emerson |

Many crops we interact with at the moment are nonetheless burdened by underperforming alarm administration methods that overload operations staffs and induce reliability danger by making it tougher for operations groups to establish evolving points. Important impacts to reliability will be made with the precise funding in optimizing the efficiency of the alarm system and offering clear identification to off-design course of situations to plant personnel.

Moreover, when off-design points have occurred, we have now seen superior management methods present higher coordinated responses because of their predictive management capabilities. These predictive capabilities permit the management actions to higher steer via transient dynamic situations and keep stability, offering the plant an elevated probability to remain on-line after a majority of these occasions.

Lastly, we’re seeing know-how enhancements on the “edge” that permit a greater convergence of data from asset well being, analytics, management, and efficiency to offer earlier detection of evolving points from crucial plant belongings earlier than they demand a real-time response from the automation system.

POWER: What are a few of the upkeep applications that may be applied to make an influence plant and/or an influence grid extra dependable? How can this upkeep be automated?

Nyenhuis: Having a proactive upkeep technique is the key towards declining operational efficiency and managing dangers to reliability. Increasingly, energy prospects expect intelligence to be constructed by default into the options they purchase. Ideally, we don’t desire a plant operator to have to note that an alarm is intermittently coming in and going out to begin a sequence of occasions that results in the identification of an under-performing cooling loop management, for example. We would like that management loop to be monitoring itself and elevating its hand, telling anyone when it wants consideration. That’s how we should be leveraging know-how.

|

|

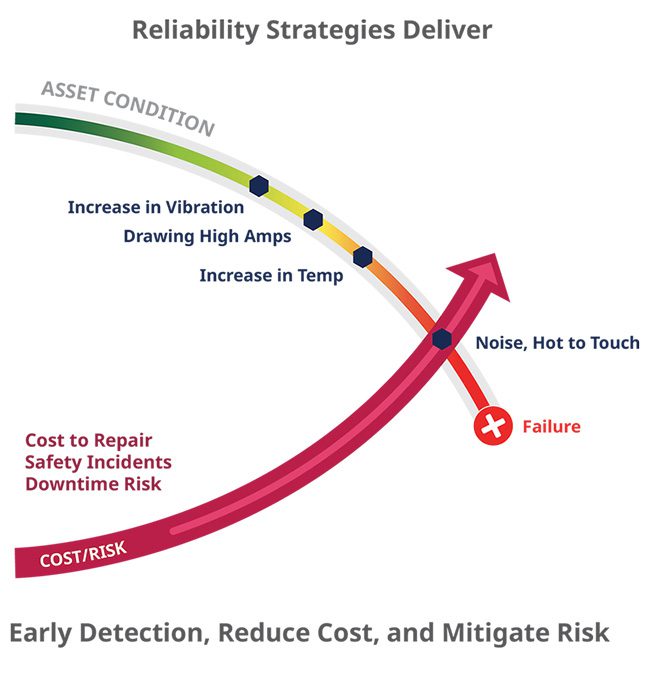

2. A proactive reliability administration technique is the key towards declining operational efficiency whereas enhancing course of availability and reducing working prices. Courtesy: Emerson |

This identical idea will be utilized to the administration of instrumentation, crucial rotating gear, management valves, and many others. New applied sciences are permitting us to attain these objectives. Developments in software program [Figure 2] permit us to robotically talk with belongings and supply automated reporting and affirmation of anticipated operation. If the necessity arises, there’s the power to proactively notify the suitable personnel through textual content or e-mail of a possible drawback that wants consideration.

POWER:How necessary is redundancy as a part of energy plant/energy grid operations?

Nyenhuis: The criticality of redundancy varies inside totally different purposes throughout the ability technology enjoying discipline. Clearly, we are going to at all times be sure that security is the highest precedence and deploy the precise degree of redundancy to take care of secure plant operations inside business finest practices. Past security issues, there will be financial tradeoffs between the funding prices in extra ranges of redundancy and the misplaced financial alternative if the plant isn’t obtainable to supply energy.

Usually, we’re seeing a pattern in the direction of leveraging software program purposes to offer a extra refined danger evaluation across the potential impacts of not having redundancy because it pertains to reaching the monetary or operational objectives of a course of. As an business we have now tended to design processes and gear round static, mounted kind assumptions, however we see this altering as the ability technology world will get extra refined and dynamic. Know-how permits us to extra precisely mannequin potential dangers with historic information and design assumptions. These instruments present quantitative methods to stability the objectives of course of availability towards the prices related to varied ranges of redundancy.

POWER: How can operations be standardized to enhance reliability?

Nyenhuis: One of many issues that we’re seeing is our prospects leveraging extra ranges of automation implementation inside their present know-how to encapsulate operational experience instantly inside the base degree automation infrastructure earlier than the present experience leaves the business. This course of forces prospects to drag the precise cross-functional group collectively, those that know the precise traits of the plant they function and keep. This results in embedding the most effective apply operational procedures in sequence automation that may be leveraged again and again, driving consistency and repeatability. Monitoring the suitable metrics over time, similar to startup occasions or gas consumption, in addition to operator interactions with the distributed management system, reveals that operational consistency is enhanced and, over an extended time horizon, reductions in general misplaced megawatt-hours have been achieved, instantly enhancing reliability objectives.

POWER: What are a few of the particular parts/gear that can be utilized to boost reliability?

Nyenhuis: We have now discovered one of the best ways to boost reliability is to look again and wade via obtainable information to know, to the diploma doable, what gadgets present up as key unfavorable contributors to a plant’s general reliability metrics.

Do explicit developments present up? What kinds of occasions have led to essentially the most misplaced manufacturing over the previous variety of years? Relying on the solutions to a majority of these questions, totally different approaches could also be referred to as for.

Can a specific system or set of methods at a plant be recognized as a key contributor? In that case, aligning particular obtainable applied sciences to handle the danger these methods pose could also be warranted.

If human efficiency elements are a big contributor to misplaced technology, overview of automation system efficiency and alarm administration implementation could make sense. There may be an abundance of helpful applied sciences out out there at the moment: the problem is aligning these applied sciences with said danger mitigation goals in as an environment friendly and cost-effective manner as doable.

POWER: How can mannequin predictive management be used to boost reliability?

Nyenhuis: We have now seen a big improve in our prospects deploying mannequin predictive management in applicable areas of the method similar to steam temperature management, drum degree management, load, and emissions management, in addition to different crucial course of areas. The impression we’re seeing to boost reliability is mannequin predictive management’s skill to higher handle crucial off design conditions.

When the management will be predictive in nature, we have now seen it have a greater skill to coordinate a number of management responses, ideally returning a course of to a secure state after a crucial upset, even whether it is at a degraded output. For instance, we have now seen mannequin predictive drum degree controls higher handle upsets to dynamic steam transition points associated to a mixed cycle bypass system. When we have now the predictive skill to steer the method via the upset, we improve the power to keep away from unit journeys, which will increase general course of reliability.

POWER: How can a program be applied to allow proactive alternative and/restoration of older gear (each software program and {hardware}) in energy plant and energy grid methods?

Nyenhuis: This effort connects to a query posed earlier and facilities round what is thought in regards to the efficient lifecycle stage of crucial belongings and methods coupled with an understanding of present signs that may be noticed. We liken this to attempting to know whether or not an growing old asset is sort of a match 82-year-old with no indication of ldl cholesterol points, regular blood strain, and a clear medical historical past, or is it an obese 74-year-old with a historical past of medical points similar to hypertension, diabetes, and excessive ldl cholesterol.

We have now the power, with know-how at the moment, to precisely observe the “age” of crucial belongings and carry out each periodic and steady checks to observe well being signs and stress ranges. Implementing these applied sciences and aggregating them into easy-to-understand outputs helps us perceive the place the “physician” must focus.

As beforehand mentioned, reviewing historic information and what could also be at present obtainable to know present “signs” helps set the stage for the place to initially focus efforts. We need to guarantee there’s a clear image of asset criticality throughout the plant. Understanding an image of historic impacts to unit reliability and guaranteeing this evaluation traces up with asset criticality lens units the stage for transfer ahead.

Ideally, we need to deploy a proactive reliability administration technique that facilities round actively monitoring the danger of growing old belongings whereas enhancing course of availability and reducing working prices. We particularly need to establish any crucial belongings that require speedy consideration. For ongoing monitoring, we need to leverage present failure mode and results evaluation (FMEA), reliability methods, work process improvement, and computerized upkeep administration software program (CMMS) integration to assist focus initially on correct danger administration of any recognized high-criticality belongings that will present indicators of extreme age or poor well being. These efforts permit us to focus on an asset administration program and related applied sciences that instantly impression recognized reliability dangers and lay a basis that helps future growth.

—Darrell Proctor is a senior editor for POWER.