Mitsubishi Energy has efficiently demonstrated partial load and full load combustion of a gas mix with 30% hydrogen (by quantity) in a grid-connected J-series Air-Cooled (JAC) gasoline turbine. The achievement carefully follows the completion of a combustion check on an ammonia single-fuel burner for coal firing by Mitsubishi Heavy Industries (MHI), Mitsubishi Energy’s mum or dad firm.

The technological breakthroughs symbolize pivotal developments for MHI, which has been working to “future-proof” its legacy thermal energy technology enterprise and supply extremely environment friendly and environmentally pleasant vitality technology choices for patrons by means of gas flexibility, together with low-carbon fuels like hydrogen and ammonia.

Beneath MHI’s “MISSION NET ZERO” technique, which goals to attain carbon neutrality for its companies and prospects by 2040, the corporate is spearheading the validation and commercialization of varied combustors for hydrogen co-firing, single-fuel hydrogen firing, and single-fuel ammonia firing. It is usually creating applied sciences “to fulfill a variety of ammonia utilization wants,” from low-ratio to high-ratio co-firing in utility and industrial boilers.

A Massive Step for an Built-in, Grid-Related System

Mitsubishi Energy’s hydrogen co-firing combustion demonstration, introduced on Nov. 30, is notably “the world’s first energy technology check on a big body gasoline turbine utilizing a gas combination of 30% hydrogen whereas related to the native energy grid and utilizing hydrogen produced and saved on the identical website,” the corporate stated.

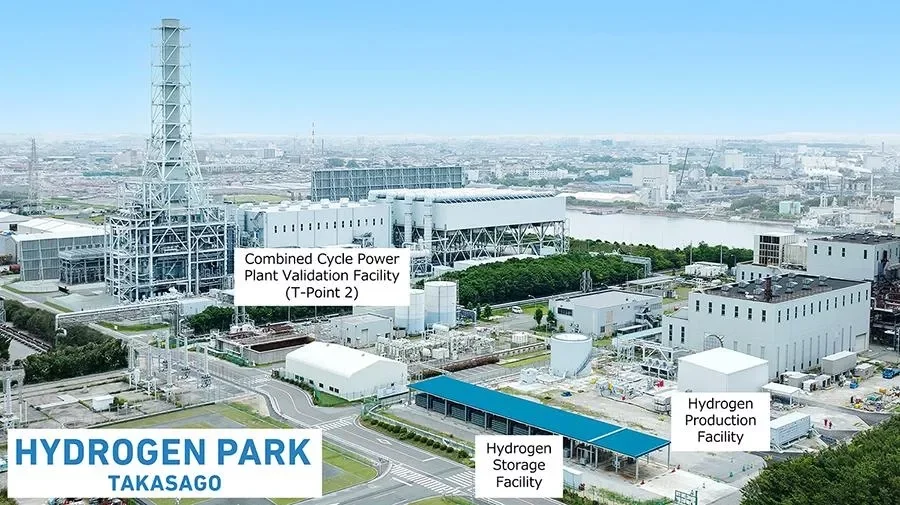

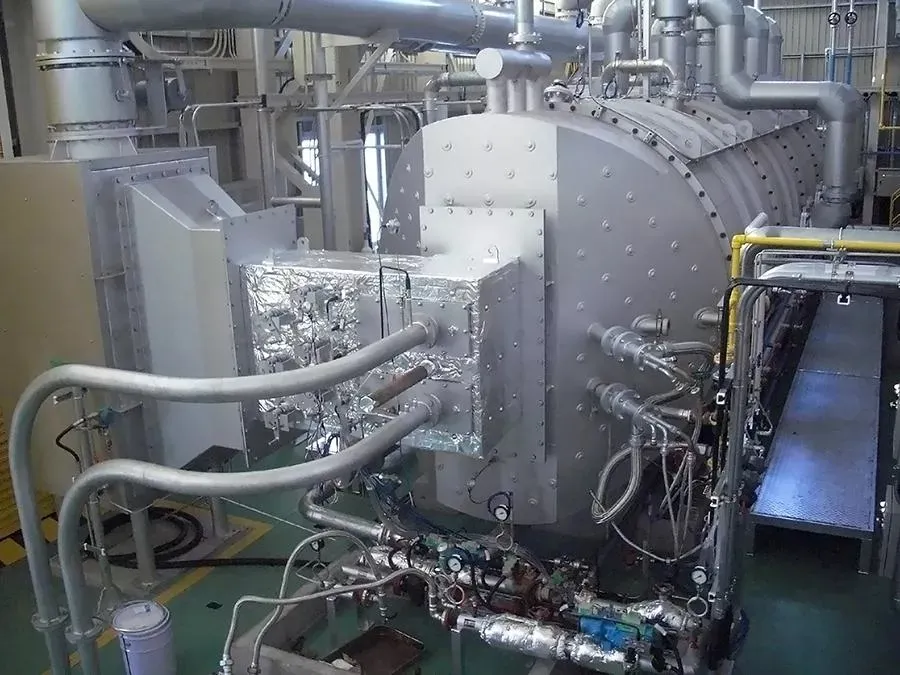

The testing was performed at T-Level 2 Mixed Cycle Energy Plant Validation Facility, Mitsubishi Energy’s devoted gasoline turbine demonstration and validation facility that uniquely received POWER’s Plant of the Yr award in 2020. T-Level 2 contains a next-generation M501JAC gasoline turbine with a rated output of 566 MW (at 60 Hz) that was grid-connected in 2020. Together with an enhanced air-cooled system for cooling the combustor, the power’s JAC turbine has a turbine inlet temperature of 1,650C and features a thicker thermal barrier coating (TBC) and a compressor with a high-pressure ratio.

T-Level 2 is housed at Takasago Hydrogen Park, an built-in hydrogen validation facility inside MHI’s Takasago Equipment Works in Hyogo Prefecture, west-central Japan. The built-in hydrogen facility started full-scale operation in September 2023.

Takasago Hydrogen Park additionally features a 5.5-MW alkaline electrolyzer, manufactured by HydrogenPro AS of Norway, that has a hydrogen manufacturing capability of 1,100Nm3/h, one of many highest on the earth. The power’s produced hydrogen is saved in storage tools with a capability of about 39,000 Nm3. Future plans name for testing and validating next-generation hydrogen manufacturing applied sciences corresponding to high-temperature steam electrolysis utilizing stable oxide electrolysis cells (SOEC), built-in validation of “turquoise” hydrogen manufacturing, its storage, and energy technology along with hydrogen manufacturing utilizing the alkaline water electrolyzer.

A Two-Half Demonstration

The profitable demonstration unveiled on Thursday entailed two components, Mitsubishi Energy stated: It “executed a gas mix of 30% hydrogen by quantity,” using hydrogen produced at Takasago Hydrogen Park; and it demonstrated the utilization of that gas in T-Level 2’s M501JAC turbine at partial load and full load.

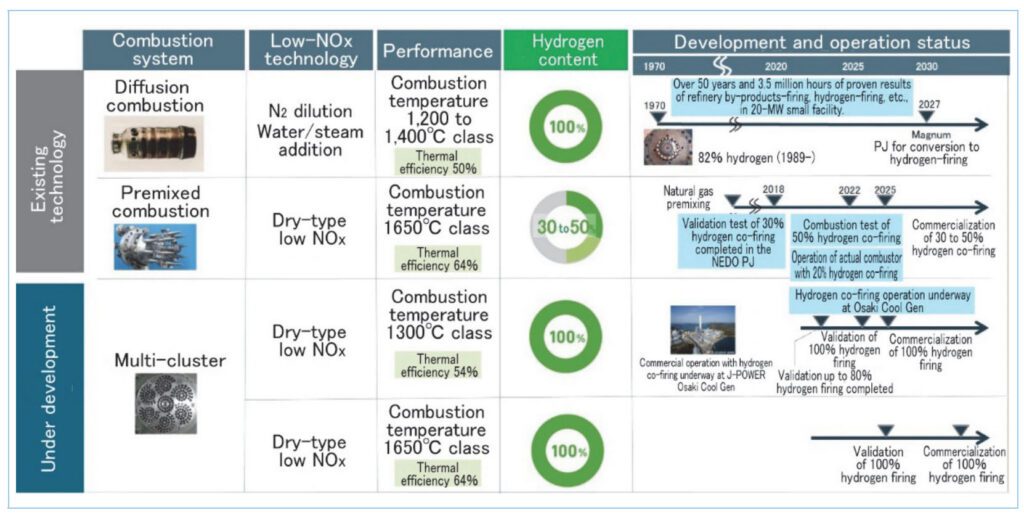

A key demonstration focus has been to confirm a dry-low NOx (DLN) pre-mixed multi-nozzle combustor expertise, which addresses flashback (backfire), combustion stress fluctuation, and nitrogen oxide (NOx) emissions. Developed with funding by Japan’s New Power and Industrial Expertise Improvement Group (NEDO), Mitsubishi Energy in 2018 validated the usage of 30% hydrogen by quantity within the massive body gasoline turbine combustor, and in 2022, it validated 50% hydrogen by quantity.

Nevertheless, the integral demonstration unveiled on Thursday “verified the achievement of the identical low NOx emissions and secure combustion throughout hydrogen co-firing, and that switching fuels from pure gasoline to hydrogen gas mixing is feasible throughout partial-load and full-load operation,” the corporate stated. In 2024, the corporate plans to “proceed with the enlargement of the hydrogen storage facility and carry out an indication utilizing a 50% hydrogen blended gas.”

To get to a 100% hydrogen functionality, the corporate has, in tandem, been creating a single-fuel “multi-cluster” combustor expertise that allows environment friendly mixing of hydrogen and air by way of an upgraded gas supply nozzle design. Hydrogen co-firing utilizing the novel combustor at a 1,300C-class gasoline turbine is underway at J-POWER’s Osaki Cool Gen venture, a 2017-completed built-in gasification mixed cycle (IGCC) plant in Hiroshima Prefecture.

Mitsubishi Energy’s improvement of a 1,650C-class multi-cluster combustor can also be underway. Combustion assessments are slated in 2025, and the firm is eyeing commercialization by 2030, “when hydrogen is anticipated to be in ample provide.”

T-Level 2, notably, additionally features a small- and mid-sized (40-MW class) H-25 gasoline turbine, which Mitsubishi Energy had beforehand put in for compressor driving on the combustion check facility. Validation of 100% hydrogen firing within the H-25 gasoline turbine, which can use the corporate’s Kind 3 Multi-Cluster combustor, is deliberate for 2024, the corporate stated on Thursday.

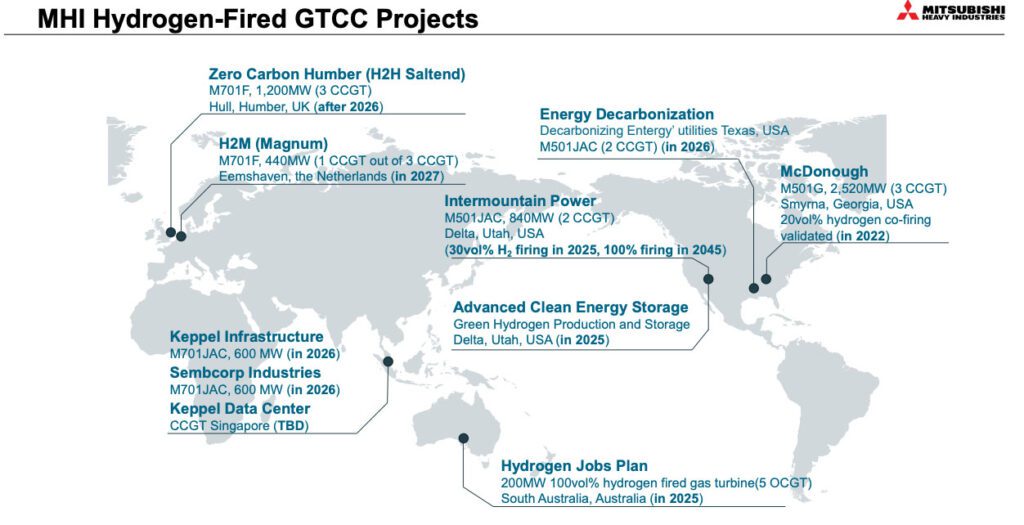

Commercialization of Mitsubishi Energy’s hydrogen capabilities shall be on full show on the Superior Clear Power Storage Challenge in Delta, Utah. The 300-GWh built-in hydrogen system that’s shaping as much as be the most important renewable hydrogen vitality hub within the U.S. envisions producing as much as 100 metric tonnes per day of hydrogen from water and renewable vitality sources utilizing a HydrogenPro 220-MW high-pressure alkaline electrolyzer financial institution. It’ll retailer that hydrogen in two gigantic solution-mined caverns sited in the one salt dome within the Western U.S after which present that hydrogen to 2 M501JAC gasoline generators, which Mitsubishi Energy not too long ago delivered to the 840-MW IPP Renewed venture.

The 2 generators shall be able to using a gas mix of 30% hydrogen by quantity once they start operation in 2025. Beneath a 20-year long-term service settlement (LTSA), Mitsubishi Energy will incrementally enhance the quantity of hydrogen within the gas combine as accessible from the adjoining ACES Delta venture to attain a 100% hydrogen combustion quantity by 2045, catering to California’s stringent mandate for carbon-free energy.

MHI Completes Ammonia Single-Gasoline Burner Take a look at for Coal Boilers

In the meantime, MHI has since 2021 been creating a burner that allows high-ratio ammonia co-firing in pulverized coal-firing boilers as a part of NEDO’s Gasoline Ammonia Provide Chain Institution venture. A key venture goal is to develop—by fiscal yr 2024—burners able to ammonia single-fuel firing for each round firing–sort and opposed firing–sort burners by means of combustion assessments “with a full-scale burner equal to precise tools.”

On Tuesday, the firm introduced it efficiently accomplished a combustion check of an ammonia single-fuel burner at its Nagasaki District Analysis & Innovation Heart, a devoted check facility in Nagasaki district, Japan.

“Using a combustion check furnace with gas consumption of 0.5 tons per hour (t/h), MHI performed a single-fuel burner check utilizing an ammonia burner and a high-ratio ammonia co-firing check with coal,” the corporate stated. “In each circumstances, the assessments confirmed secure combustion, decreased NOx emissions in comparison with coal firing, and full combustion of the ammonia.”

Subsequent, MHI plans to conduct a combustion check utilizing an actual-sized burner in “a bigger 4t/h combustion check furnace.” Primarily based on that check, MHI will then “take steps for utility of the burner it has developed for thermal energy vegetation in Japan and abroad,” it stated.

MHI, notably, is working with Japanese energy generator JERA—a three way partnership between Tokyo Electrical Energy Co. (TEPCO) and Chubu Electrical that’s trying to shift its huge coal-fired fleet to 100% ammonia by 2050—on the venture. In 2022, the businesses stated they deliberate to “draw up a grasp plan for tools to exhibit its use in precise boilers.” The 2 corporations are anticipated to determine whether or not to put in the burners at JERA’s coal-fired boilers made by MHI. “For the precise plant demonstrations, JERA and MHI plan to confirm co-firing with at the least 50% ammonia at two items with totally different boiler sorts by FY 2028,” they prompt.

JERA—a three way partnership between Tokyo Electrical Energy Co. (TEPCO) and Chubu Electrical that’s trying to shift its huge coal-fired fleet to 100% ammonia by 2050—is already working to determine the expertise and co-fire as much as 20% ammonia at the 1-GW Unit 4 of JERA’s 4.1-GW Hekinan Thermal Energy Station, starting in fiscal yr 2024. On Nov. 29, JERA President Hisahide Okuda informed reporters the venture is on observe to start in March 2024. Plans name for growing ammonia co-firing to greater than 50%, with an precise energy plant demonstration in 2028/2029, and probably the beginning of economic operation within the early 2030s.

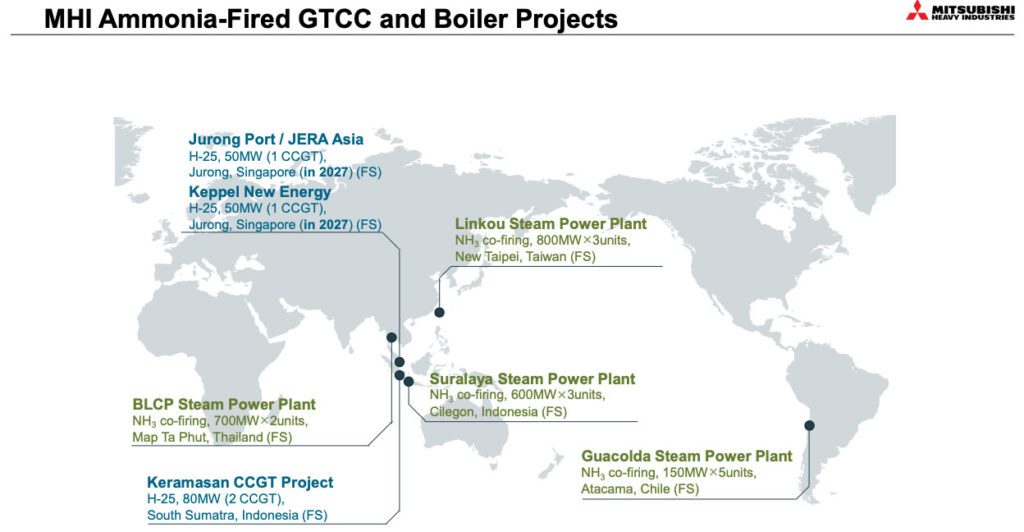

Earlier this yr, JERA and MHI signed a memorandum of understanding (MOU) with Thailand’s Electrical energy Producing Public Firm Ltd. to evaluate the feasibility of as much as 20% ammonia co-firing on the 1.4-GW coal-fired BLCP energy plant. JERA, in the meantime, has MOUs to review ammonia co-firing with Aboitiz Energy, a coal generator within the Phillippines. MHI has the same settlement with Chilean unbiased energy producer Guacolda Energia, in addition to a number of different entities.

MHI Individually Exploring Alternatives for Ammonia Fuel Combustion

MHI and JERA have joined forces to discover ammonia-firing in gasoline generators, too. In August 2022, the 2 corporations got down to collectively discover establishing a 100% ammonia-fired mixed cycle plant on Jurong Island in Singapore. Beneath an MOU, the 2 entities will research establishing a 60-MW class gasoline turbine mixed cycle plant.

Jurong Island, notably, has emerged as a hotspot for hydrogen and ammonia combustion exercise. MHI is, as well as, fielding one other potential alternative with Singapore vitality infrastructure developer Keppel Infrastructure and DNV for a 100% ammonia-fueled gasoline turbine or mixed cycle system. And as POWER not too long ago reported, Sembcorp Industries, GE Vernova, and Japanese heavy trade agency IHI Corp. are additionally collectively inspecting probably retrofitting two GE 9F gasoline generators at an 815-MW gas-fired mixed cycle energy plant in Singapore with ammonia capabilities.

MHI notes that it began improvement of a single-fuel ammonia combustor for gasoline turbine energy technology in 2021. Mitsubishi Energy, notably, is main the cost to develop a 40-MW class gasoline turbine that may instantly combust 100% ammonia.

The corporate is presently understanding how you can instantly combust ammonia utilizing a Kind 1 diffusion combustor whereas eradicating NOx byproducts brought on by oxidation ensuing from the combustion of the nitrogen part of the gas.

One answer, which is utilized to the corporate’s H-25 gasoline turbine collection, combines a gasoline turbine system with NOx removing tools. Plans, for now, goal probably pairing an ammonia-fired combustor with an “ultra-high-performance denitration facility.” In tandem, the corporate is evaluating the usage of waste warmth from gasoline generators in mixed cycle techniques to reconvert ammonia into hydrogen and nitrogen. An precise plant validation may happen in 2025, it suggests.

—Sonal Patel is a POWER senior affiliate editor (@sonalcpatel, @POWERmagazine).