Gasoline flexibility could also be a key driver for current developments in gensets, however the perennial objectives of decreasing CapEx and OpEx stay.

Gasoline flexibility is without doubt one of the pillars of decarbonization that’s being embraced by genset OEMs. Gasoline effectivity, a second pillar, goes hand in hand with that as a result of new fuels will likely be dearer, however these issues come along with the on-going drive to cut back CapEx and OpEx for shipowners.

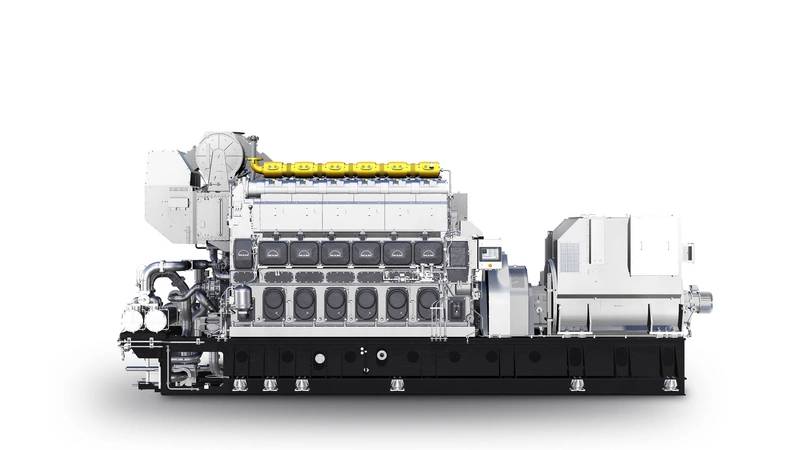

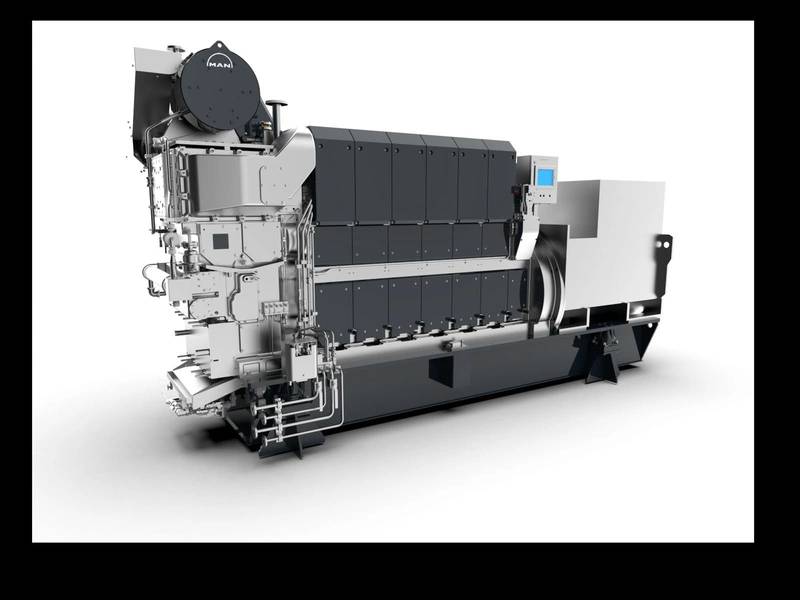

MAN Power Options launched its auxiliary MAN 35/44DF CD engine in June 2023. It’s designed to be future-proof and will likely be prepared for methanol operation by 2026. Sephardim Koblenz, Head of Licensing, MAN Power Answers, notes although: “Each shipyards and shipowners tremendously respect auxiliary engines which are simply put in and maintained, whereas reliability and cost-optimization are additionally key.”

MAN additionally not too long ago obtained its first order for small-bore, seven-cylinder MAN 21/31DF-M methanol-burning gensets for six PCTCs being constructed by China Retailers Heavy Trade for China Retailers Power Transport. The 21/31DF-M relies on a easy port fuel-injection idea that optimizes reliability, whereas concurrently minimizing capital outlay.

“The inspiration for the brand new L21/31DF-M genset is the prevailing L21/31 genset which has collected greater than 55 million working hours with 1000’s of engines in service,” says Bjarne Foldager, Senior Vice President and Head of Two-Stroke Enterprise. “The L21/31DF-M energy vary spans 1,000-1,980kW, which makes it appropriate for many service provider vessels.”

Foldager expects methanol to determine prominently as a future gas throughout all vessel segments. “The brand new genset advantages from the excessive reliability, excessive efficiency and gas flexibility of the 21/31 engine platform, whereas the chance to function on inexperienced methanol as a drop-in gas will increase its fuel-flexibility. Concurrently, it additionally will increase methanol’s potential as an possibility for genset energy technology aboard massive marine service provider vessels.”

Bjarne Foldager: The L21/31DF-M energy vary spans 1,000-1,980kW, which makes it appropriate for many service provider vessels. Picture courtesy MAN ES

Bjarne Foldager: The L21/31DF-M energy vary spans 1,000-1,980kW, which makes it appropriate for many service provider vessels. Picture courtesy MAN ES

Different OEMs even have new gas developments on-going. HHI-EMD has developed a 4-stroke HiMSEN methanol engine, and Caterpillar Marine is designing alternative-fuel gensets with a present deal with methanol. Yanmar Energy Know-how is concurrently growing hydrogen, ammonia and methanol engines and has commercialized a hydrogen gas cell system.

Volvo Penta and CMB.TECH have collaborated to create dual-fuel, hydrogen engines, and CMB.TECH’s collaboration with DBR has seen the event of twin gas hydrogen gensets. The core of the expertise is the confirmed MAN V12-24l engine. The genset has a most output of 940kVA / 752 kWe at 60 Hz (1800 rpm) and might function on diesel or in twin gas mode the place emission financial savings of as much as 83% will be achieved. The genset can also be accessible in 50Hz (1500rpm) which might ship 822kVA of energy.

Wärtsilä introduced in August that it’ll provide methanol-fueled Wärtsilä 32M auxiliary gensets for six 15,000 TEU container ships that are being constructed on the Dalian Shipbuilding for CMA CGM. Future fuels improvement is a key a part of Wärtsilä’s decarbonization technique, however when requested what a very powerful developments in gensets had been, Janne Klemola, Normal Supervisor, Product Administration – Wärtsilä Marine Energy, mentioned: maximizing gas effectivity.

“That’s why some of the necessary developments in gensets is round enhancing the reliability of the facility – this may help with driving greater gas effectivity and in flip decreasing total emissions from a vessel. What’s extra, if it’s also possible to lengthen the time wanted between overhauls and/or main repairs – via utilizing innovative synthetic intelligence and superior diagnostics – this may help vessel homeowners enhance asset effectivity and scale back each working prices and emissions.”

Janne Klemola: Some of the necessary developments in gensets is round enhancing the reliability of the facility. Picture courtesy of Wärtsilä.

Janne Klemola: Some of the necessary developments in gensets is round enhancing the reliability of the facility. Picture courtesy of Wärtsilä.

Klemola sees this as half of a bigger endeavor to proceed to refine and improve genset expertise. One other half is the continuing improvement of genset automation and integration of controls with different techniques, comparable to power storage techniques.

Mark Harrison, Product Technique Supervisor for Caterpillar Marine, says: “An important developments that we’re seeing in gensets in the mean time is how they’re being utilized in another way in fashionable energy techniques. How can we finest make the most of batteries, hybrids, and gensets in concord to realize our aims? Can these advantages overcome the inherent CapEx and OpEx challenges? At Caterpillar, we’re specializing in total system effectivity: Are our mills optimally sized? Are these mills working at peak effectivity? Can we begin or cease a genset to function at a extra environment friendly level from an total vessel perspective? Are we optimizing the utilization of electrons versus gas molecules for one of the best mix of reliability and effectivity?”

The times of merely specifying in gensets appears to be fading shortly, he says. “Clients now must determine greater than ever if bigger gensets for reliability are extra necessary than smaller, extra energy dense ones, based mostly on how they’re anticipated to function in actual life. One particular change we expect is the mills of the longer term (built-in into hybrid techniques) will function at a lot greater load components. Have we optimized the gensets for this new actuality?”

Volvo Penta and CMB.TECH have collaborated to create dual-fuel, hydrogen engines. Picture courtesy of CMB.TECH.

Volvo Penta and CMB.TECH have collaborated to create dual-fuel, hydrogen engines. Picture courtesy of CMB.TECH.

A modular, hybrid and fuel-flexible strategy to onboard energy has the potential change serious about gensets and ship design, and it’s turning into evident in newbuilding orders. Dutch transport firm Transtal Transport has signed a contract with Thecla Bodewes Shipyards for the development of a 5,100-dwt diesel-electric multi-purpose vessel. Gasoline flexibility is vital to the design which contains three gensets and two electrical motors. The vessel is prepared for future fuels comparable to methanol or hydrogen, with area reserved on board for different power sources with out having to exchange the electrical propulsion system.

Sam Gombra, co-founder of ÈTA Transport, got here up with a extremely versatile answer for a coastal cargo ship. The design, ÈTA 6700, is initially diesel-electric, however is designed in order that it could sail on methanol, ammonia or hydrogen sooner or later. There is no such thing as a predominant engine. Initially, energy is supplied by three 600kW Mitsubishi mills, every put in in its personal container, however it’s doable to include any containerized sustainable energy supply. Gombra estimates that it’ll take lower than a day to take away the prevailing energy technology system and exchange it, with out the necessity for a shipyard. The corporate has already partnered with Mercuria on a sequence of vessels anticipated to be delivered beginning in 2025.

Transtal Transport and Mercuria are demonstrating the need for gas flexibility shipowners have as they endeavor to stability regulation with expertise developments and economics. Genset OEMs are working to make sure their CapEx and OpEx will be minimized as effectively.

MAN has obtained its first order for small-bore, seven-cylinder MAN 21/31DF-M methanol-burning gensets for six PCTCs. Picture courtesy of MAN Power Options

MAN has obtained its first order for small-bore, seven-cylinder MAN 21/31DF-M methanol-burning gensets for six PCTCs. Picture courtesy of MAN Power Options