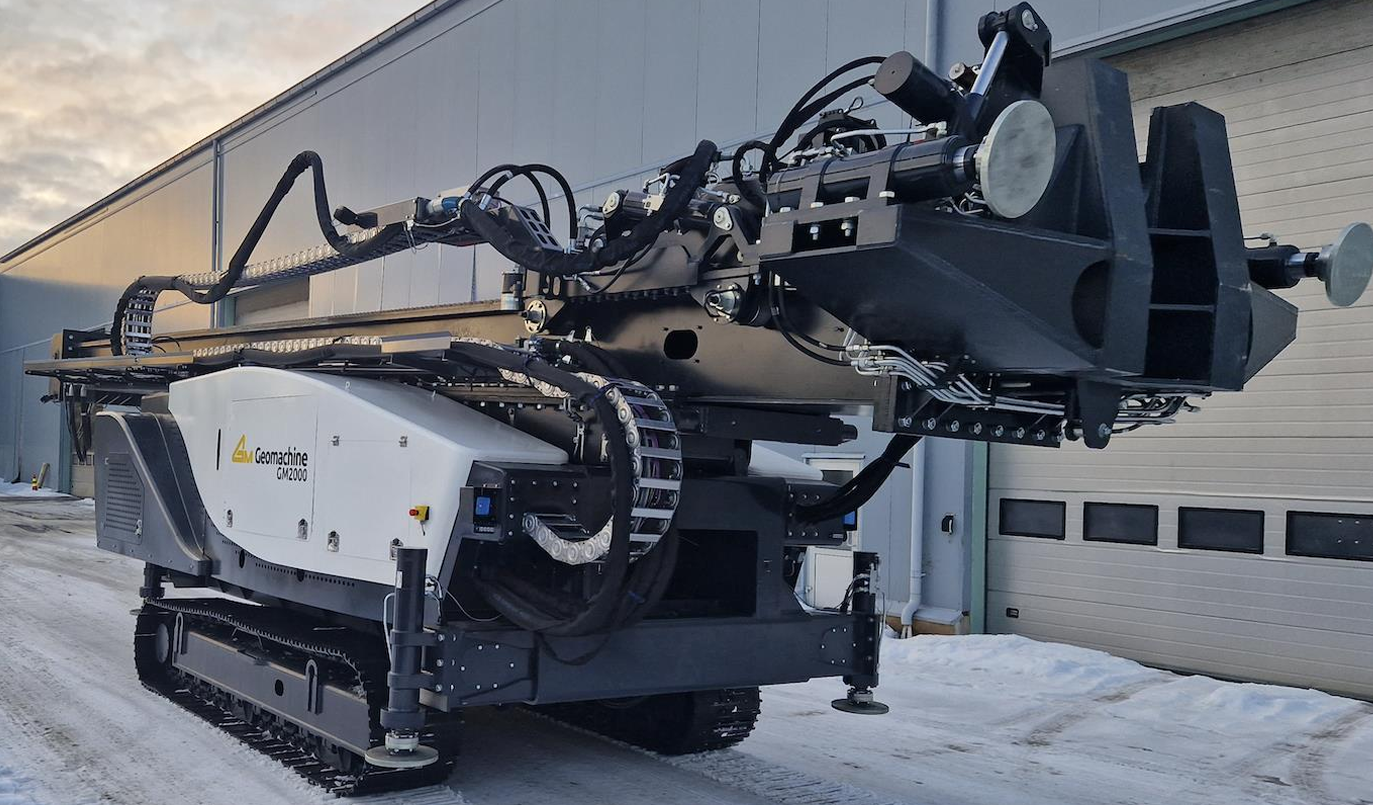

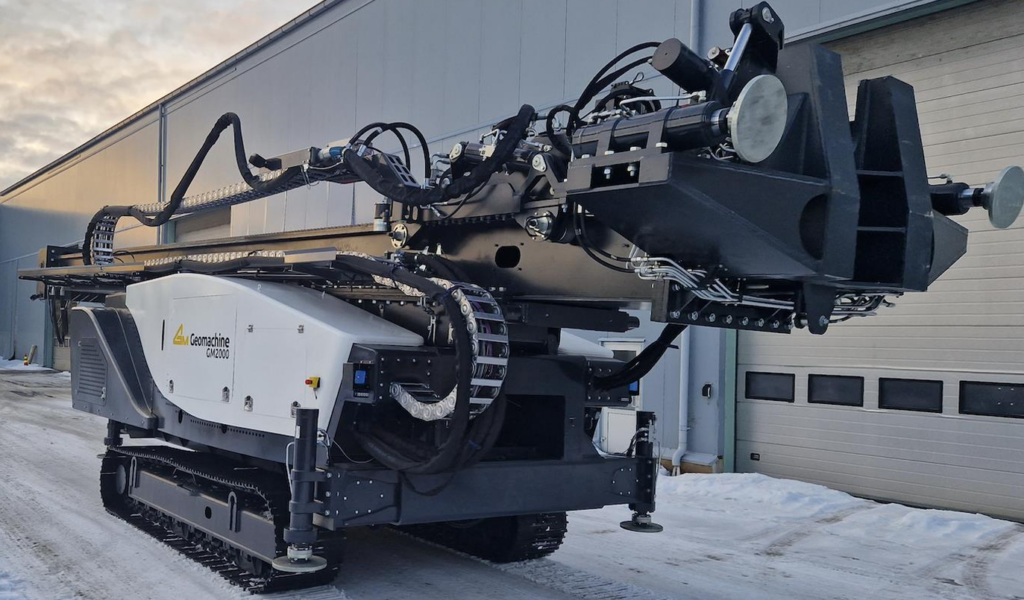

The GM2000 drilling rig by Geomachine and developed with QHeat is an progressive drilling rig integrating automation and IoT applied sciences.

Just a few weeks in the past, a geothermal mission on the website of waste incineration plant by Lounavoima set a brand new file with the drilling of a thermal effectively to a depth of 2008 meters. Drilling to this depth permits for a lot better thermal output and thermal storage capability for the waste incineration plant.

The developer behind the geothermal mission is the know-how firm QHeat, which had additionally been concerned in a geothermal district heating mission in Vantaa, Finland earlier this yr. One other essential element within the execution of the Lounavoima mission is the GM2000 drilling know-how by Geomachine.

An built-in drilling resolution

The GM2000 effectively drilling know-how is not only a drilling rig, however an entire geothermal drilling resolution that features a compressed air system and an clever management and recording system for optimizing the drilling course of.

“After we began searching for a sensible implementer for our innovation a number of years in the past, we realized that there was no experience in deep geothermal effectively drilling in Finland. Geomachine has a long time of expertise in floor investigation and down-the-hole hammer drilling, so we engaged in discussions about refining our idea with them. It turned clear that that they had the experience wanted to develop the drilling rig,” mentioned Erika Salmenvaara, CEO of QHeat.

In designing the GM2000 effectively drilling rig, particular consideration has been given to total cost-effectiveness, automated information recording, real-time evaluation of the drilling course of, and work security. “The adoption of the GM2000 resolution has introduced numerous advantages. Drillers’ job satisfaction has improved as a result of they now have a contemporary instrument at their disposal. Work is safer, and drillers are not uncovered to emissions because the rig could be managed remotely. Because of the rig’s data-driven management, the driller is aware of what is occurring within the gap always. General, work has turn out to be safer and of upper high quality.”

Simple mobilization and quick deployment are a number of the different key options of GM2000. It’s small in dimension, simple to move, and quick to arrange for drilling.

From driller to course of operator

Automation is a crucial a part of the design means of the GM2000. By a CAN-bus management system, automated drilling could be completed with GM Weight-on-Bit (WoB) management. This retains the drill bit stress at pre-defined goal ranges, thus optimizing the drilling velocity whereas minimizing put on and harm on the bit.

The tilting rotary head is automated to work along with the feeding desk for the loading and unloading of the drill string. Opening and tightening of the rod connections are made simple with a hydraulic clamp and sliding rod holder. All operations are protected by a security radar system. All this makes drilling protected, quick, and simple for the operator.

Utilizing the GMTrackerDTH data-logging software program, effectively drilling information collected, monitored in real-time, analyzed, and reported. The drilling progress could be recorded and tracked graphically. The values monitored embody drilling feed velocity, rotation velocity and torque, feed pressure, and drill bit stress. When utilizing a Geomachine compressor, the data-logger also can monitor the compressor’s gasoline consumption, drilling stress and air quantity. The operator also can add notes to the drilling progress chart.

Machine studying is likely one of the superior options of the GMTrackerDTH. The operator can select the monitored indicators, after which the software program suggests changes based mostly on what it learns throughout drilling.

GMTrackerDTH permits information evaluation over a number of drilling websites and gear decisions to search out essentially the most economical values for the drilling course of and allow predictability. The information-logger mechanically measures soil composition and data rock socket connections and rock fractures, so it can be used as a reporting instrument.

All this helps to make sure a profitable drilling course of even in difficult situations. The function of the machine operator modifications from a driller to a course of controller.

Collaboration results in outstanding feats

Based on Erika Salmenvaara, the collaboration with Geomachine is a superb instance of how combining forces can result in a wonderful end result. “Our mission is to help our prospects on their carbon neutrality journey, significantly in heating. Our product is clear heating vitality. Geomachine, however, affords the answer for virtually implementing our mission. Although we function in several industries, we now have discovered true synergy in reaching a standard good.”

Each QHeat and Geomachine profit from this collaboration in rising their respective companies. “For us, collaboration permits us to promote our innovation as a tangible product to those that want it. Geomachine, however, provides a brand new resolution to their product portfolio, increasing their choices from floor investigation to geothermal vitality drilling.”

Sooner or later, the Geomachine drilling resolution can be marketed to actual property traders, district heating builders, development firms, and huge property homeowners. There are additionally plans to enhance the GM2000 with a provision for connection to an electrical powerline. Geomachine’s mission is to contribute to taking the geothermal effectively drilling business to a brand new and extra productive period.

Supply: Geomachine