A consortium that features energy business giants Siemens Vitality and ENGIE stated it accomplished what the group referred to as the world’s first operational check of a gasoline turbine fueled with 100% renewable hydrogen.

Siemens Vitality on Oct. 13 stated the HYFLEXPOWER consortium performed the check utilizing a gasoline turbine at Smurfit Kappa, a paper packaging firm in Saillat-sur-Vienne, France. The consortium additionally contains Centrax, a UK-based gasoline turbine producer; Arttic, a French consultancy; the German Aerospace Middle, often known as DLR; and 4 Europe-based universities.

The challenge in France entails producing and storing renewable hydrogen on the Smurfit Kappa web site. Smurfit Kappa is headquartered in Dublin, Eire. The corporate produces corrugated packaging, containerboard, and different paper packaging merchandise.

Pursuing a Hydrogen-Fueled Turbine Fleet

“The data and expertise gained from the HYFLEXPOWER challenge the place we put in the primary gasoline turbine to run on 100% hydrogen will assist us to proceed develop our whole gasoline turbine fleet for a hydrogen-based future,” stated Karim Amin, member of the chief board of Siemens Vitality. “The interplay between electrolysis, storage, and hydrogen conversion at one web site has been impressively demonstrated, and now it’s a matter of scaling the outcomes.”

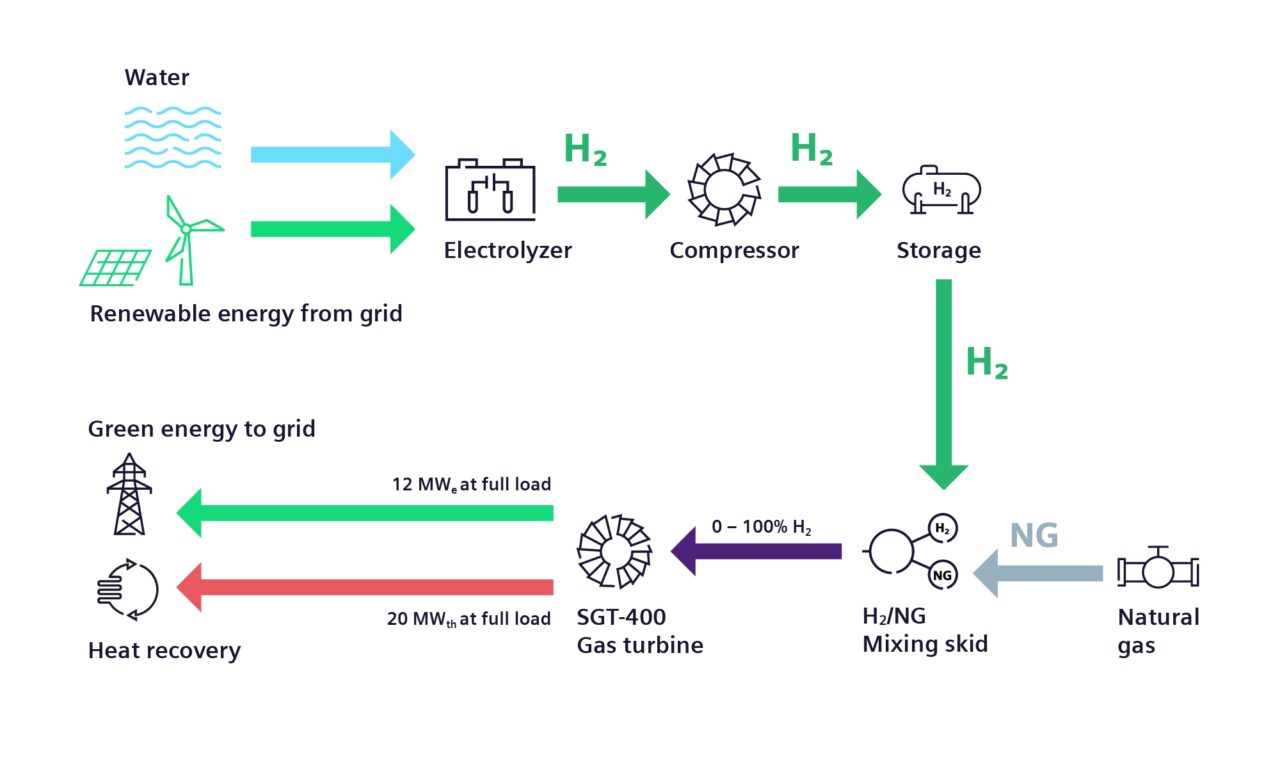

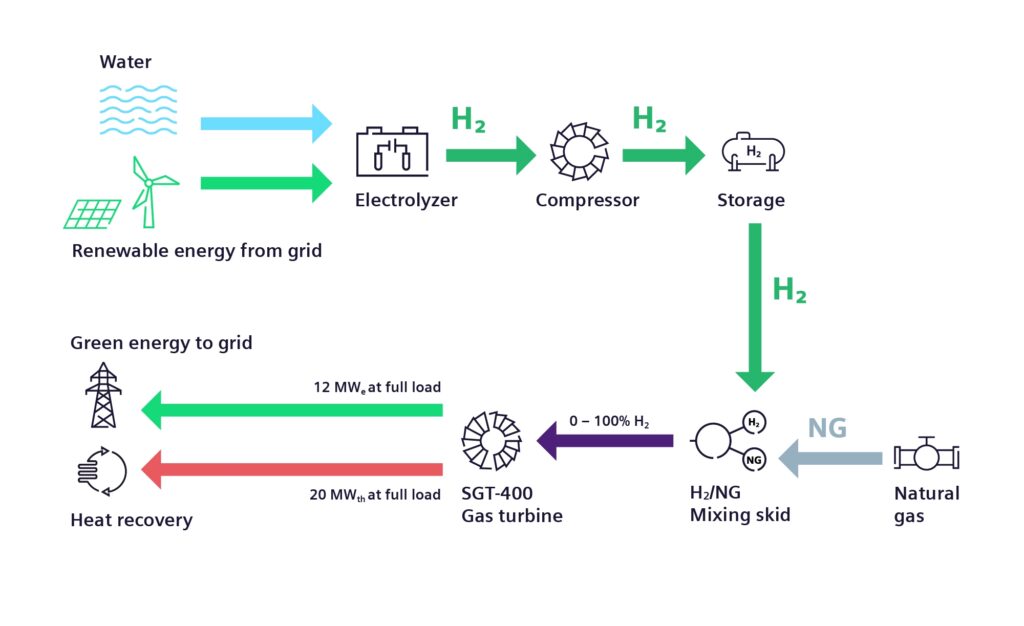

The hydrogen on the French manufacturing facility is produced by a 1-MW electrolyzer on the web site. It’s then saved in what Siemens referred to as “an virtually one-ton tank and used to energy a Siemens Vitality SGT-400 industrial gasoline turbine.” Siemens stated the challenge “demonstrates that hydrogen can be utilized as a versatile vitality storage medium, and that it’s additionally potential to transform an current gas-fired energy turbine to function utilizing renewable hydrogen.”

“We’re proud that our Saillat paper mill has been the host for this challenge as a result of trialing new and rising know-how, similar to hydrogen, aligns with our decarbonization technique and Higher Planet 2050 journey. At present’s announcement is a superb milestone that places us in good stead,” stated Garrett Quinn, chief sustainability officer at Smurfit Kappa.

Siemens Vitality, which is main the consortium, stated the success of the HYFLEXPOWER demonstration in France already has led to a deliberate enlargement of the group to incorporate extra members. Siemens in a information launch wrote, “Having examined HYFLEXPOWER for electrical energy manufacturing, the aim is now to increase its operation to industrial warmth manufacturing and extra operational modes. It is usually deliberate to discover methods of scaling up and commercializing decarbonized electrical energy technology.”

Need to study extra about Siemens Vitality and its efforts to help a hydrogen financial system? Learn this particular report, “On the Daybreak of the Hydrogen Financial system,” and likewise learn this commentary from an organization govt within the September 2023 concern of POWER.

The group has stated utilizing renewable hydrogen would help accelerated decarbonization efforts for energy-intensive industries. Siemens Vitality provided the electrolyzer for hydrogen manufacturing, and likewise developed the hydrogen gasoline turbine. Engie has been in control of manufacturing, storage, and the availability of hydrogen for the challenge. Centrax has up to date the system for protected hydrogen gas operation.

‘Pleased with this World First’

“At ENGIE, we’re very pleased with this world first,” stated Frank Lacroix, the corporate’s govt vp in control of Vitality Options. “The HYFLEXPOWER challenge is outstanding for a lot of causes: for the distinctive collaboration it has enabled between a number of European companions, for the forward-looking applied sciences it has examined, and for the promising prospects it opens up for the usage of renewable hydrogen within the industrial sectors most tough to decarbonize. We stay up for persevering with this decisive work for the way forward for decarbonized business with our companions.”

The German Aerospace Middle (DLR), together with the colleges of Lund, Duisburg-Essen, and College School London, have contributed to the challenge, serving to develop the hydrogen turbine know-how. Arttic supported the challenge’s operational administration. The group stated the Nationwide Polytechnic College of Athens performed an financial, environmental, and social evaluation of the challenge’s idea.

Undertaking in Normandy

Siemens Vitality additionally just lately introduced it will provide 12 electrolyzers with a complete capability of 200 MW to Air Liquide’s Normand’Hy challenge in Normandy, France. Air Liquide, a world gasoline and know-how firm, will function the electrolyzers on the firm’s plant within the Port-Jérôme industrial zone, starting in 2026.

The businesses stated the plant will produce 28,000 tones of renewable hydrogen yearly to be used by business and the transportation sector. Siemens Vitality and Air Liquide in 2021 introduced an settlement to work on hydrogen know-how tasks.

“The sustainable decarbonization of business is unthinkable with out inexperienced hydrogen. That’s the reason tasks like this are so vital,” stated Anne-Laure de Chammard, member of the chief board of Siemens Vitality. “However they’ll solely be a place to begin for a sustainable transformation of the economic panorama. Different large-scale tasks should comply with shortly. For the event of a European hydrogen financial system to succeed, we’d like dependable help from policymakers and simplified procedures for funding and approving such tasks.”

Siemens Vitality stated the electrolyzers on the Normandy web site will probably be primarily based on proton alternate membrane know-how, or PEM electrolysis. That know-how is appropriate with an intermittent renewable vitality provide because of its brief ramp-up time and dynamic controllability, in keeping with Siemens, which stated it “well-suited for the speedy ramp-up of the hydrogen business as a result of its excessive vitality density and small footprint and materials necessities.”

The Normand’Hy challenge will probably be one of many first to be provided from Siemens Vitality’s new electrolyzer manufacturing facility in Berlin, Germany. It’s a part of the framework of the beforehand talked about three way partnership between Air Liquide and Siemens Vitality, which incorporates industrial sequence manufacturing of stacks—thought of the center of PEM electrolyzers—that may begin in November. Siemens Vitality has stated that manufacturing is anticipated to extend to no less than 3 GW by 2025, which may assist provide hydrogen tasks worldwide.

—Darrell Proctor is a senior affiliate editor for POWER (@POWERmagazine).