The aggressive panorama in shipbuilding has modified dramatically, as ‘Business 4.0’ capabilities pushed by the digital revolution have given the sting to those who scout and undertake options that ship on the promise of accelerating effectivity whereas slicing prices. Juan Prieto discusses the CADMATIC suite of options for North American shipyards searching for to seize the aggressive edge.

Digital applied sciences are evolving at breakneck velocity, unlocking super effectivity good points for shipbuilders. Juan Prieto, Americas regional supervisor at software program firm CADMATIC, mentioned there are lots of alternatives for shipbuilders, particularly in the US, to undertake these options.

“Right here within the U.S., the [shipbuilding] digital revolution, or Business 4.0, remains to be in very early phases, however we will see that increasingly individuals are speaking about it,” Prieto mentioned, noting that CADMATIC opened a North American workplace about two years in the past. “We’re going slowly towards this digital revolution. There’s nonetheless a protracted technique to go right here, however that is additionally the identical in Europe and in Asia. I would not say that we’re too far behind.”

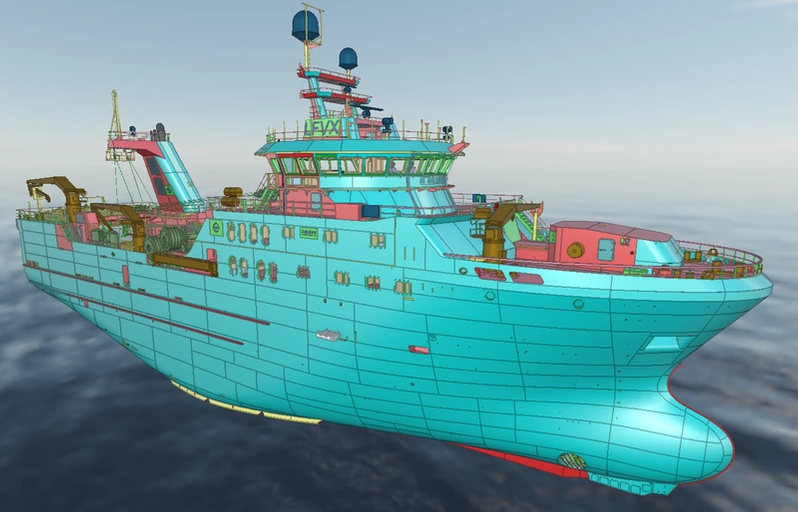

(Picture: CADMATIC)

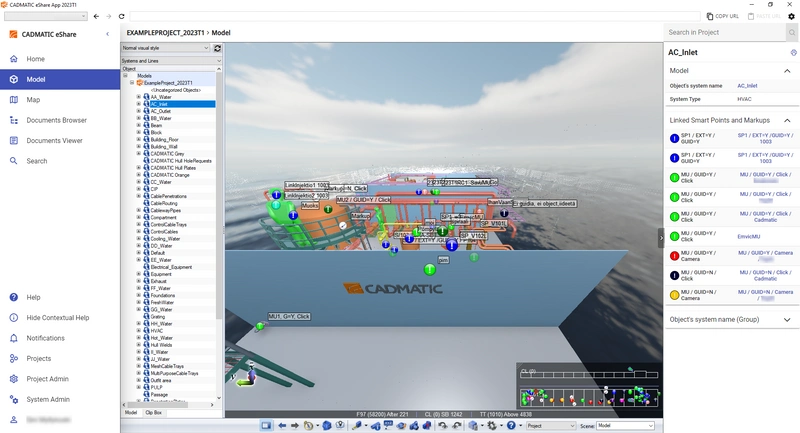

(Picture: CADMATIC)

CADMATIC has been serving the shipbuilding sector for the reason that early Nineteen Eighties, starting with merchandise to include 3D know-how to enhance design, visualization, distribution and complete value effectivity. The agency has grown considerably since then, and its product providing has too. Right this moment CADMATIC markets a full suite of digital and clever 3D-based design, engineering and knowledge administration software program options for the marine business.

“We offer options all the way in which from the essential design to manufacturing, and in addition later to operations,” Prieto mentioned. “We offer all options that shipyards want to have the ability to construct their ships effectively with decrease prices.”

Prieto mentioned a standard drawback right this moment is that shipbuilding cycle processes—all the way in which from design to manufacturing—are sometimes carried out in silos that not often talk to one another.

Below its “data administration” umbrella, CADMATIC affords an progressive software program suite particularly designed to assist handle this challenge.

“CADMATIC’s eShare is a platform the place the shipyard can join all of their techniques into one 3D mannequin,” Prieto mentioned. “You may test ERP [enterprise resource planning] issues or data, MRP [material requirements planning], the 3D mannequin itself, both coming from CADMATIC or opponents, AutoCAD drawings, Excel; all of them connect with eShare.”

CADMATIC’s eShare providing permits data to be built-in and revealed from numerous enterprise techniques and fragmented documentation in a single, easy-to-use net portal accessible by all stakeholders. (Picture: CADMATIC)

CADMATIC’s eShare providing permits data to be built-in and revealed from numerous enterprise techniques and fragmented documentation in a single, easy-to-use net portal accessible by all stakeholders. (Picture: CADMATIC)

eShare seamlessly hyperlinks mission information, together with the 3D mannequin, exterior databases or administration techniques, and makes all available to mission stakeholders in a shared net portal. The answer basically ensures that no matter its supply, whether or not design functions or the manufacturing and operation of a vessel, the collected information is clear and accessible, that means larger mission effectivity. As well as, data produced throughout all phases of a mission lifecycle can be utilized as constructing blocks for the vessel’s digital twin.

The final word purpose is to bridge the communications hole in order that shipyards can construct extra effectively and scale back prices, Prieto defined. “That goes all the way in which from the communications, from the design to the manufacturing, and in addition later to the operations of the shipowner to allow them to incorporate the adjustments that they’ve from the operations again to their design.”