As energy era embraces digitization, and appears for extra reliability and suppleness, the necessity for superior instrumentation and management programs grows.

Energy plant operators know the significance of sustaining a strong instrumentation and management (I&C) system, one which precisely supplies the data wanted to make sure the protected and dependable operation of their facility.

It begins with the design of the system, continues with its set up, after which is supported with upkeep that allows steady, optimum plant efficiency. Monitoring and regulating the processes concerned with energy era services is constantly being improved as programs present real-time knowledge on working situations, which permits operators to make better-informed choices and be proactive in relation to facility upkeep and extra.

Software program and {hardware} that helps I&C processes has turn out to be extra adaptable, and extra user-friendly—essential at a time when extra energy crops are changing to digitization in an business consistently evolving throughout the vitality transition.

“It’s management that issues,” mentioned John Arnaud, supervisor of Strategic Accounts and Partnerships at Lumin, an vitality administration options supplier. “We want extra perception in relation to controlling hundreds behind the meter. We’re working with utility companions, and serving to with residential demand response, with the kind of applied sciences that allow a utility to see these hundreds.”

A contemporary, superior I&C system performs a serious position within the worthwhile operation of an influence plant. It helps the utmost availability of a era facility, whether or not thermal or renewable—and even battery vitality storage—and in addition helps reliability, flexibility, and operations and upkeep methods. An excellent I&C system additionally might help in sustaining emissions compliance.

The transfer towards digitization has improved communication between operators and tools, as software program and {hardware} turn out to be extra adaptable. That helps the management of apparatus in addition to help providers throughout an influence era facility.

Lennart Hinrichs, vice chairman of Partnerships at TWAICE, a battery software program platform group, advised POWER, “Information varieties the inspiration for any analytics and optimization case. To make use of battery storage operators for example, they will leverage knowledge for predictive analytics to extend the supply of their storage and enhance the general effectivity by anticipating upkeep wants. This preemptive strategy with analytics ensures that battery storage programs usually are not solely working easily but in addition prevents pricey outages.”

Monitoring Efficiency

I&C programs are chargeable for monitoring and regulating quite a lot of energy plant parameters, together with strain, stream, stage, temperature, and general high quality in a facility. At present’s programs present real-time knowledge on course of situations, which supplies operators extra perception into plant efficiency, and permits steps to take care of optimum operation and stop points that might end in downtime.

“Effectivity optimization is one other vital space for knowledge,” mentioned Hinrichs, who famous the elevated significance of I&C in relation to vitality storage, which at present typically is paired with energy era each at thermal and renewable vitality websites. “Analytics platforms present detailed insights into battery utilization and degradation, which permits operators to regulate charging and discharging cycles for optimum effectivity and to attenuate put on, thereby preserving the battery’s capability and prolonging its service life.”

Effectivity and productiveness are two focuses of an I&C system, as Hinrichs famous. There’s the potential for quicker response instances to alerts and faults, together with via the usage of distant monitoring of energy era belongings. Engineers working to design I&C programs can make the most of superior management algorithms, knowledge analytics, and different strategies to enhance course of operations, and help general plant efficiency.

Hinrichs advised POWER, “Moreover, knowledge analytics can be utilized to optimize the operational parameters,” serving to operators “perceive how completely different utilization patterns have an effect on the longevity of their belongings and permits them to plan for replacements or upgrades in an economical method.”

Management on the Manufacturing facility

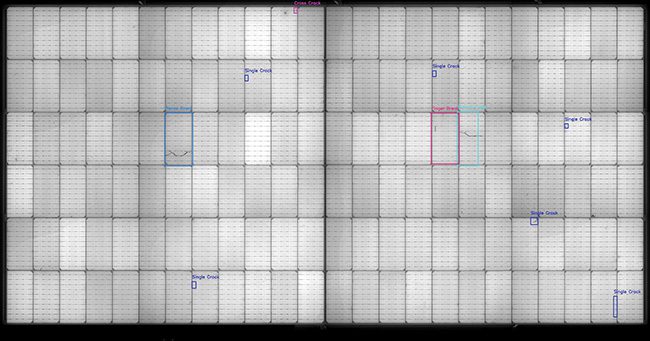

Energy era tools producers are recognizing how I&C strategies can enhance era belongings earlier than they’re deployed. Sinovoltaics, a solar energy tools firm with headquarters in Hong Kong and Shanghai, China, not too long ago entered the U.S. market with its Sinovoltaics EL Mass Evaluation (SELMA) know-how, a proprietary electro luminescence (EL) product that makes use of synthetic intelligence (AI) to determine microcracks (Determine 1) and different module defects earlier than tools is shipped to installers.

|

|

1. Sinovoltaics’ SELMA know-how makes use of synthetic intelligence to determine microcracks and different defects in photo voltaic modules earlier than they’re shipped to installers. Courtesy: Sinovoltaics |

“EL is a course of that’s a part of each photo voltaic course of, as soon as earlier than lamination, [and] on the finish of the manufacturing line, to verify there aren’t any defects,” mentioned Arthur Claire, head of Expertise for Sinovoltaics. “Each producer is doing an EL check on the finish of the manufacturing line. You’ll have an image of every panel, and would have about two seconds to search for defects… plenty of panels with defects that ought to have been taken out of the manufacturing line have been being shipped to purchasers.”

With Sinovoltaics’ course of, Claire mentioned, “we will calibrate the machines, [and have] 1000’s of images associated to every module. We will analyze with SELMA, and verify to see whether or not it agrees with high quality requirements. We will discover and reject these modules earlier than they get shipped.” Claire, who spoke with POWER on the InterSolar occasion in San Diego, California, in January, mentioned it offers photo voltaic tools producers one other stage of management in relation to their merchandise.

Claire mentioned that “at present within the U.S., it’s actually widespread for corporations that buy from Southeast Asia and different international locations to do sampling. They could go to the manufacturing unit and monitor the manufacturing line—do pre-shipment inspections. However what number of modules are you supposed to examine? Sinovoltaics’ software program inspects each single one, versus sampling. I’m fairly snug saying we’re the corporate inspecting probably the most modules on this planet at present.”

Claire continued: “Module manufacturing is a quantity enterprise, most of it performed by robots. Factories want high quality requirements to outline whether or not [the product] is nice or not. We now have large expertise in Asia, and now we have U.S. corporations asking us to come back to their factories to assist with their manufacturing course of.”

Upkeep and Reliability

Engineers concerned within the design of I&C programs acknowledge the significance of monitoring tools, together with enabling of proactive upkeep to make well timed repairs and decrease downtime. The economics of at present’s energy era put a premium on availability and reliability.

|

2. Utilities are creating centralized, distant operation collaboration facilities to optimize assets and enhance efficiency. Using built-in management, monitoring, and analytics supplies insights that may detect anomalies, enabling the management system or an operator to take motion. Courtesy: Emerson |

Rick Kephart, vice chairman of Expertise for Emerson, advised POWER that when tools monitoring, significantly distant monitoring, “The important thing components are much less about appropriate conditions and extra about delivering insights, actionable intelligence, and outcomes to the fitting personas. For points that may be sudden or catastrophic, groups want someone close by who can intervene. That may imply a management operator who’s stationed onsite, however it may additionally imply prioritizing knowledge supply so an operator in a distant management heart [Figure 2] has the data they want once they want it.”

Distributed energy era, together with elevated interplay between utilities and their clients on the residential stage, has produced a necessity for I&C programs to facilitate that communication. Lumin, which supplies {hardware} and software program options in that house, not too long ago unveiled its latest residential load management platform, Lumin Edge. Arnaud spoke with POWER at InterSolar about how the product merges Lumin’s clever load administration software program with a modular design, offering the system with new performance. The Lumin Edge pre-release program, by which the corporate not too long ago shipped models to co-op and investor-owned utilities throughout the U.S. and Canada, focuses on grid providers equivalent to high-resolution, behind-the-meter analytics, and superior demand-side administration instruments.

“Management is one factor, however with the ability to present insights to the shopper via the Lumin app is also essential,” mentioned Arnaud. “Then there are the insights the utility would acquire, significantly at a granular stage—what home equipment are being turned on, who’s charging an EV—it’ll be actually attention-grabbing as we’re working with plenty of utility corporations. And clients can opt-in or opt-out of demand response.”

Arnaud mentioned the push towards electrification means utilities are dealing with extra strain to take care of grid stability. The Lumin Edge supplies behind-the-meter analytics and presents real-time load administration capabilities, which are supposed to assist grid operators form demand with extra precision. It additionally permits electrical energy clients extra perception into more and more complicated utility price constructions. The modular design of the Lumin Edge Controller means it may be positioned wherever alongside the wire, from a house’s service panel to a focused equipment. The controllers talk wirelessly with the Edge Hub via a safe mesh community. “The client will get actually cool know-how, and entry to plenty of utility applications with incentives,” mentioned Arnaud.

Recognizing Cyber Threats

Cybersecurity is receiving extra consideration as an integral a part of I&C programs. Chris Stangl, managing director of Berkeley Analysis Group’s Cybersecurity and Investigations apply, advised POWER, “Ideally, this must be a strategic enterprise resolution knowledgeable by an intensive danger evaluation. Earlier than introducing new know-how, it’s essential to conduct an evaluation to find out the chance of a menace actor exploiting a possible vulnerability within the technical implementation.”

Stangl, who spent greater than 20 years as an FBI Particular Agent within the company’s Cyber Division, together with as a member of the Senior Government Service, has investigated a broad vary of cyber circumstances together with hacking by each cybercriminals and nation-state actors, and has addressed counterintelligence and insider threats.

“Within the occasion of a profitable assault, the evaluation ought to consider the potential affect on the confidentiality, integrity, or availability of data and assets,” mentioned Stangl. “Notably within the realm of operational know-how and industrial management programs [ICSs], the place there’s potential for repercussions on public security or nationwide safety, a danger evaluation is crucial. The outcomes of such an evaluation must be methodically thought of when considering the implementation of distant monitoring.”

Stangl continued: “When contemplating connecting legacy ICSs, initially designed to be remoted, to the Web, particular consideration is warranted. This features a complete understanding of related dangers, a well-funded program to safeguard these vital belongings, steady monitoring, and a meticulously documented and practiced response plan.”

—Darrell Proctor is a senior affiliate editor for POWER (@POWERmagazine).