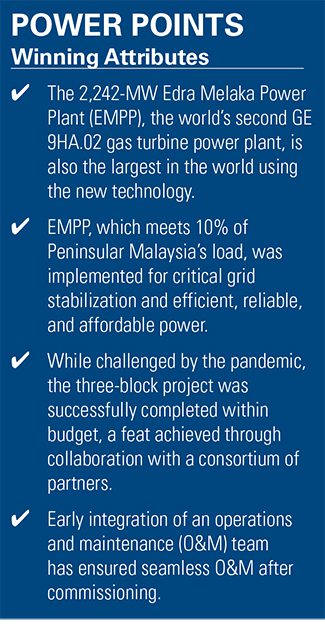

The Edra Melaka Energy Plant (EMPP), the world’s second GE 9HA.02 fuel turbine energy plant, is the biggest mixed cycle gas-fired energy plant at present in operation in Malaysia. A POWER Prime Plant winner, the mission features as a vital transitional set up that balances the nation’s reliability, power affordability, and sustainability initiatives.

Malaysia has made assertive leaps over the previous decade to reshape its home power panorama in order that it matches inside the palpable shift within the worldwide stance on sustainability, however nonetheless reliably shoulders load development from its burgeoning manufacturing and providers economic system, and leverages its indigenous fuel sources to make sure power safety at reasonably priced costs. Underneath a just lately issued Nationwide Vitality Transition Roadmap, the Southeast Asian nation will section out nearly all of its put in coal energy capability—which comprised 37% of its whole combine in 2021—by 2050, with 7 GW anticipated to be retired by 2033. The nation will as an alternative search to spice up its renewables capability share to 70% (58% of which could possibly be photo voltaic PV) by 2050. Recognizing potential provide shortfalls from its speedy tempo of coal retirements within the years approaching 2029, Malaysia has just lately outlined a fuel energy build-out that leverages extra fashionable and environment friendly mixed cycle fuel turbine (CCGT) energy plant expertise.

One of many first initiatives introduced on-line underneath an accredited fast-track era improvement plan for Peninsular Malaysia was Southern Energy Era’s 1.4-GW Monitor 4A (Sultan Ibrahim Energy Plant) in Pasir Gudang, a mission that received POWER’s 2021 Plant of the 12 months award for its myriad attributes, together with that it showcased the primary pair of business GE 9HA.02 fuel generators. In February 2022, Edra Melaka Energy Plant (EMPP), a three-block 2.2-GW CCGT plant owned by Edra Energy Holdings Sdn. Bhd., started industrial operation in Alor Gajah, Melaka State—successfully turning into the world’s second 9HA.02 CCGT mission. (A 3rd 1.4-GW 9HA.02 mission at Bang Pakong in Thailand has since been accomplished.)

Essential for Grid Stability

The achievement is a major milestone for Edra, an organization fashioned in 2014 from the consolidation of three main Malaysian unbiased energy producers (IPPs). Because the second largest IPP in Malaysia, Edra secured the “construct, personal and function” concession (beforehand referred to as Monitor 4B). Edra turned a subsidiary of China Basic Nuclear Energy Corp. (CGN) in 2016 and subsequently in 2018, China Southern Energy Grid Co., Ltd (CSG) invested in Edra by taking over a 37% curiosity within the firm.

In line with Edra, the EMPP was mandatory to boost regional energy provide reliability and sustainability. Whereas the Peninsula Malaysia’s southwestern coast is seeing booming financial development owing to its thriving providers, manufacturing, and agricultural sectors, it has confronted a “variety of retired energy crops, in addition to having operated a number of energy crops with low-efficient mixed cycle energy crops, corresponding to E and F fuel generators,” Edra famous. The area has additionally grappled with “shortage of fossil gasoline availability along with the necessities to additional restrict greenhouse fuel (GHG) emission to a single digit,” it stated.

At full operation, EMPP generates about 19.6 GWh yearly, contributing to about 10% of Peninsular Malaysia’s demand, Edra famous. The large scale of the plant—every of its three 745-MW single-shaft producing blocks features a GE 9HA.02 fuel turbine, an STF-D650 steam turbine, a W88 generator, and a GE warmth restoration steam generator (HRSG)—was additionally mandatory to make sure grid stability and economically aggressive energy costs. As such a major contributor to systemwide provide, the plant types a vital system section. That’s why the mission was designed as “blocks,” Anbarasan Sellappan, deputy chief operation officer at Edra, instructed POWER. “The system stays dependable with unit-based synchronization.”

Diligent Mission Execution Regardless of Challenges

Nevertheless, getting the enormous plant constructed required cautious mission administration and diligent execution. Edra, notably, confronted a good schedule dictated by a 2017-signed 21-year energy buy settlement (PPA) secured with Tenaga Nasional Bhd. (TNB), Malaysia’s largest electrical utility. The PPA stipulated a development interval from the discover to proceed (NTP) of 36 months for the primary block, 38 months for the second block, and 40 months for the third block, focusing on full industrial operation by Could 2021. All three blocks in the end achieved industrial operations consecutively in December 2021, January 2022, and February 2022.

“There was definitely an pressing want to finish the mission on time in an effort to fulfill its PPA obligation to attain industrial operation inside the specified dates,” Edra stated. Delays posed liabilities of liquidated damages, it famous. However whereas the mission initially progressed forward of schedule for 2 months, “like every other initiatives world wide, it was sadly affected by the COVID-19 pandemic, which has resulted in closure of the mission web site,” Edra famous. Nonetheless, regardless of the pandemic-related delays, the mission “was delivered with agile execution, highest high quality requirements, and inside funds,” it stated. “Notably, the ability plant has to-date achieved shut to fifteen million protected man-hours with none misplaced time damage (since development commenced),” it burdened.

Edra credit the achievement to “arduous work and powerful collaborative efforts” by the mission’s huge group. Together with Edra’s devoted mission group, consisting of Edra Group Enterprise and Mission Growth, and its Group Operations and Upkeep (O&M), the mission was spearheaded by a consortium of Hyundai Engineering, Hyundai Engineering and Building, and Hyundai Engineering Malaysia Sdn. Bhd., which served because the engineering, procurement, and development (EPC) contractor. GE served as the unique tools producer (OEM), and Jacobs Engineering Malaysia Sdn. Bhd. was its proprietor’s engineer. Edra famous it procured EPC and OEM contracts via aggressive bids.

Chopping-Edge Know-how

An enormous draw to pick out 9HA.02 fuel generators (Determine 1)—although demonstrated solely as soon as worldwide at Monitor 4A—was “GE provided essentially the most aggressive provide by way of technical and industrial facets,” Anbarasan famous. Essential for plant efficiency was that the 9HA.02, rated at 838 MW underneath Worldwide Requirements Group (ISO) circumstances, pushes web effectivity past 64%. The expertise additionally affords a hot-mode startup time of lower than half-hour, a quick ramp charge of as much as 88 MW per minute to cater for automated era management (AGC) and quick frequency response to assist the grid, and a low turndown to minimal emission-compliance load.

In line with Edra, the 9HA.02’s normal dry low-NO x (DLN) 2.6e+ combustion capabilities had been additionally well-suited for compliance with Malaysia’s clear air laws. As considerably, its flexibility capabilities embody a standby and response mode of lower than 15% load and hydrogen readiness of as much as 50%. On the Melaka plant, prominently, GE’s equipped HRSGs “are designed to supply dependable high-cycling obligation because of the modern single-row harp configuration within the entrance (scorching) finish of the HRSG, producing 3 times much less stress than standard multi-row harps,” the OEM instructed POWER. The design is tailor-made for quick begins, speedy response, and low turndown, it stated.

|

|

1. Three energy crops operating seven GE 9HA.02 high-efficiency, air-cooled fuel generators are at present in industrial operation: Monitor 4A (2021) and Edra Melaka Energy Plant (2022) in Malaysia, and Bang Pakong in Thailand (2022). GE says that the HA fleet has reached over 2 million working hours, and up to now, the 9HA.02 fleet has accomplished greater than 100,000 operating hours for the seven models in industrial operation plus 4 models at present in commissioning. Courtesy: GE Vernova |

Lastly, the bundle provided security integrity degree (SIL) safety utilizing the GE Mark VIe distributed management system, offering added security to the grid system and total plant security compliance. GE additionally provided Edra a holistic resolution, together with the core energy plant tools, a 21-year service settlement, and digital options to handle all mission lifecycle facets. “It’s vital to think about particular mission necessities and evaluate the generators’ capabilities, as totally different functions might have distinctive wants,” Edra famous. “GE’s 9HA.02 has gained recognition out there for its total effectivity, energy output, flexibility, and superior options.”

Hitting the Highway Operating

Expertise gained from a observe report as an IPP with a 5-GW fleet in 5 nations proved important for Edra to make sure the sleek execution of the mission’s improvement and development phases. To satisfy the tight mission timeframe, for instance, the Hyundai consortium, Jacobs, and Edra kicked off engineering work earlier than issuance of the NTP, which was issued in December 2017 underneath a restricted NTP. One other prescient resolution was that Edra sought to maximise localized provide chains, requiring EPC companions to supply tools, supplies, and providers from Malaysian subcontractors and suppliers.

Edra additionally actively concerned lenders throughout mission execution to make sure transparency, which resulted in “good monetary well being” of the mission. In line with Anbarasan, “Transparency was additionally integral” in guaranteeing the comparatively new expertise would operate as designed. “With out transparency, there isn’t any collaboration, and with that there are many points [a customer and OEM] can resolve collectively,” he stated.

Yet one more exceptional facet of Edra’s mission administration strategy was proactively planning for “manpower competency and correct handover” to attenuate O&M gaps. “In plenty of initiatives, they may have a development group, and as soon as the plant has been commissioned, there shall be a brand new operations and upkeep group to take over,” he stated. “On this mission, for the primary time, I imagine in Malaysia, we had an O&M built-in into the mission group,” he stated.

The “shadow” group, primarily comprising senior O&M employees, was engaged within the mission from its preliminary development section to, for instance, “run via all of the engineering drawings, the product, and so forth,” Edra added. “As soon as we reached core commissioning, we began including extra individuals [to the O&M team] to make sure they transfer with the mission with the OEM,” it stated. “With the hands-on expertise throughout development and commissioning section, and the legacy energy crops expertise, the group working as a part of the mission was then transformed to essentially the most competent O&M group.”

—Sonal Patel is a POWER senior affiliate editor (@sonalcpatel, @POWERmagazine).