A global crew of researchers has proposed a collection of processes to get well silicon and different metals from recycled photo voltaic cells. Their aim is to reuse the recovered silicon within the PV provide chain.

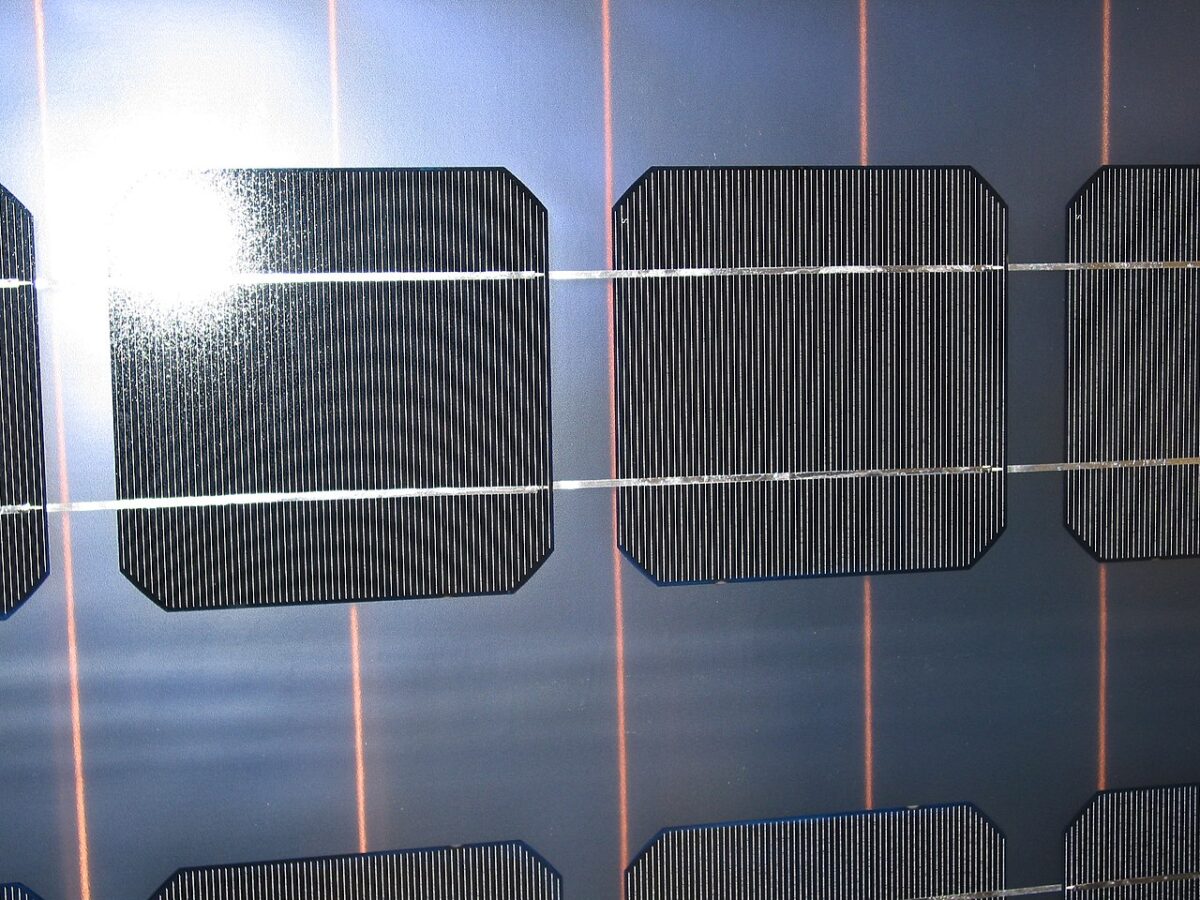

A European group of scientists has investigated the technical feasibility of bodily restoration of the metallic contacts from photo voltaic cells extracted from end-of-life photo voltaic panels and the qualification of the recovered silicon for its reuse within the PV provide chain.

“This actuality urgently requires the design and adoption of reasonably priced, efficient, and big methods of recycling and re-utilization of all PV elements, and significantly of these most energy-demanding of their manufacturing and thus accountable for the biggest quote of environmental influence: the photo voltaic cells,” the scientists defined.

Demetallization

For the metallic contact restoration, the group used potassium hydroxide (KOH)-ethanol-water options to optimize the demetallization course of. It examined varied configurations of the answer on outdated monocrystalline photo voltaic cells. The entrance contacts of the cells had been made with silver screen-printing paste, as had been the rear contacts, though additionally they contained traces of different metals, resembling aluminum, iron, or lead.

“The working situations for every experiment had been as follows: 105 min dipping in 250 mL of etching resolution, with stable/liquid ratio of 0.004 g/mL, magnetic stirring, and temperature starting from 60 C to 70 C,” the scientists mentioned. Pre- and post-treatments had been carried out to attenuate the eventual presence of impurities on the floor of the pattern.

The demetallization experiments had three variables – totally different operation temperatures (60 C, 65 C, and 70 C), totally different KOH parts (10%, 15%, and 20%), and totally different ethanol charges (5%, 10%, and 15%). The method was carried out in a 250 mL tall beaker the place the cell fragments had been launched in a vertical place held by plastic forceps.

“The design of experiments permits concluding that the temperature is essentially the most influential parameter on the burden loss and the demetallization price, whereas the ethanol-temperature interplay is essentially the most influential issue on minority service lifetime,” they mentioned. “Processing at a temperature of 60 C in a ten% KOH – 5% ethanol resolution for 105 min is discovered as the most suitable choice for the restoration of pure metals whereas preserving as a lot silicon as potential.”

Recrystallization

As for the method of recrystallizing the recovered silicon, the educational began with “cleaned fragments of outdated B-doped multicrystalline industrial wafers”, that had been manufactured within the 2000′s. They used a Czochralski (Cz) grower to create an ingot, which was then sliced into 79 wafers. These underwent phosphorous diffusion gettering (PDG) processes, as a way to enhance their transport properties.

“After profitable progress and slicing in wafers, a radical optoelectronic characterization program has been carried out,” famous the analysis group. “It demonstrated the achievement of the fundamental necessities wanted to make new photo voltaic cells, by way of wafer resistivity (round 1 Ω cm), oxygen content material (round 1,018 cm3), mobility (round 1,000 cm2/V⋅s), and service lifetimes (above 100 μs threshold in all circumstances and reaching most values of 350 μs).”

The group used the recovered supplies to fabricate phosphorus/aluminum again floor area (P/Al-BSF) photo voltaic cells. The construction included evaporated metallic contacts, with titanium/palladium/silver (Ti/Pd/Ag) for the entrance contact and Al for the rear. Lastly, I-V traits had been obtained below one-sun illumination to 4 cells and in comparison with a reference.

“From our outcomes, we conclude that the primary limitations in system efficiency noticed in gadgets fabricated from recrystallized materials and demetallized wafer fragments aren’t attributable to materials high quality degradation finally incurred through the restoration and utilization levels of the silicon substrates however relatively to pitfalls throughout cell manufacturing,” concluded the crew.

Its evaluation was introduced within the paper “Validation of recycling processes for demetallisation and recrystallization of silicon photo voltaic cells,” revealed in Photo voltaic Vitality. The analysis was carried out by scientists from Spain’s Complutense College of Madrid, Polytechnic College of Madrid, and Germany’s Leibniz Institute for Crystal Development (IKZ).

This content material is protected by copyright and will not be reused. If you wish to cooperate with us and wish to reuse a few of our content material, please contact: editors@pv-magazine.com.