Effectivity, security, and offering help for optimum efficiency are key issues when selecting tools to maneuver water and fuels via an influence plant.

Energy plant operators know the significance of pumps and piping methods to the efficiency of their facility. A number of several types of pumps can be utilized in energy vegetation, with a variety of purposes.

This contains boiler feed pumps, that are often multistage and used to ship feedwater to boilers. Different pump applied sciences embrace tools to spice up feeds and deal with condensate, together with condenser and boiler circulating pumps, heater drain pumps, and extra.

These pumps work in live performance with piping methods to help plumbing in addition to transfer water, gasoline, steam, oil, chemical substances, compressed air, and in some instances ash or slurry. These methods additionally help hearth safety, together with heating, cooling, and air-con in energy vegetation and different industrial amenities.

Piping methods typically are labeled relying on the kind of materials used within the pipe, which might be metallic or non-metallic, a composite, or an internally lined system. These methods can affect the effectivity of an influence plant, which may decide whether or not a technology facility can optimize its energy output and its economics.

“Vitality-efficient pumps cut back working prices and environmental affect, aligning with sustainability targets,” mentioned Campbell Tourgis, government vp and COO at Wainbee, one among Canada’s largest industrial distributors. “Customization ensures pumps meet distinctive operational necessities, enhancing reliability and compatibility with present infrastructure.”

Tourgis instructed POWER, “One of the vital essential pumps in energy vegetation at the moment is centrifugal. These hydraulic machines transfer massive volumes of liquid via a pipe to transform mechanical power into hydraulic energy… centrifugal pumps powered by synthetic intelligence [AI] have sturdy knowledge analytics and built-in sensors, optimizing efficiency and bettering operational effectivity.

“With developments in AI know-how, piping methods will vastly improve analyzing knowledge on strain, temperature, flowrates, and vibration,” mentioned Tourgis. “[The technology] can detect and anticipate potential failures, which prevents expensive downtime and repairs. Engineers can design and simulate piping methods via computational fluid dynamics simulations, bettering effectivity, reliability, and security in new installations.”

Environment friendly, Secure Operation

Peter Gaydon is deputy government director of the Hydraulic Institute (HI), a U.S.-based group that’s thought-about a world authority on pumps and pump methods (Determine 1). The HI develops business requirements via an array of technical assets together with utility guidebooks, on-line instruments, and calculators. Gaydon instructed POWER, “Pumps have gotten extra related in that they will have built-in sensors to help in figuring out if they’re working correctly and effectively.”

|

|

1. The Hydraulic Institute develops business requirements for industrial pumps, protecting operators abreast of the most recent applied sciences, together with for methods utilized in energy vegetation. Courtesy: Hydraulic Institute |

Gaydon mentioned energy plant operators additionally want to have a look at security issues when selecting pumps and piping methods. “Security is a vital merchandise to concentrate on, and must be the primary merchandise mentioned,” mentioned Gaydon.

“When deciding on pump know-how for energy vegetation, security is paramount,” mentioned Tourgis. “This entails incorporating leak detection methods to promptly determine and deal with potential leaks, stopping hazardous fluid releases. Overpressure safety mechanisms stop the pump from exceeding secure strain limits, decreasing the danger of apparatus harm or catastrophic failures. Fail-safe mechanisms robotically shut down the pump throughout vital failures, minimizing tools harm and the potential for accidents or accidents.”

Tourgis additionally instructed POWER, “With the rise of digital applied sciences, knowledge safety is essential in pump know-how. Producers are implementing sturdy safety measures and encryption methods in clever centrifugal pumps to guard transmitted and saved knowledge. These measures safeguard operational info, stop unauthorized entry, and guarantee pump reliability in fashionable energy vegetation.”

Software Concerns

The specialists on pumps and piping methods who spoke with POWER mentioned energy plant operators ought to concentrate on the particular utility required by the know-how to make the only option on the subject of selecting tools.

“As vegetation [are] turning into more and more automated some organizations are selecting to pick pump designs which can be simpler to service,” mentioned Pablo Martinez-Moore, industrial and advertising and marketing director at North Ridge Pumps, a UK-based industrial and marine pump provider. “[This is] a technique which pays dividends the place entry to extremely technical or extremely certified employees is tough, or briefly provide. There are some designs of pumps that are a better preliminary funding however a lot faster to service, or have the choice for ‘pump inserts’ the place the primary working elements of pumps may be simply modified, thus not requiring difficult or time-consuming service.”

“There are lots of pump sorts utilized in energy vegetation and it’s tough to rank the significance as a result of all of them serve a devoted goal,” mentioned Gaydon. “Nonetheless, if we concentrate on the feedwater system, the condensate pumps begin the method by pumping saturated water to heaters and finally to the boiler feed pumps. The boiler feed pumps then pump the liquid into the boiler.”

Gaydon instructed POWER: “These pumps are engineered particularly for the demanding utility issues. For instance, the condensate pumps are designed to have low internet optimistic suction head [NPSH] necessities as a result of the liquid could be very near its vapor strain, and the boiler feed pumps are designed for top flowrates and excessive differential pressures in order that the feedwater may be compelled into the boiler.”

|

|

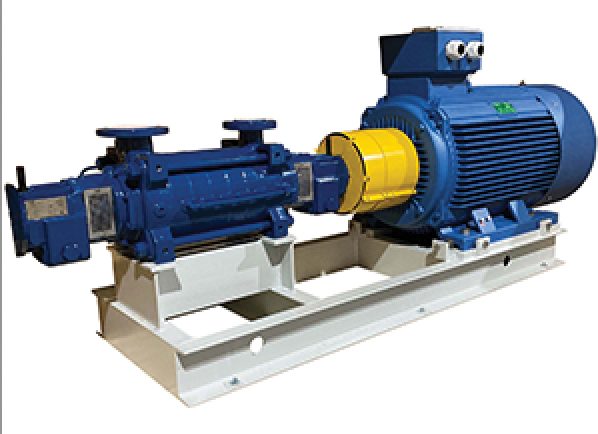

2. This multistage boiler feed pump could be one of the vital power-consuming pumps inside an influence plant. Correct upkeep of such pumps is essential for continued optimum efficiency. Courtesy: North Ridge Pumps |

“Boiler feed pumps [Figure 2] are variable pace to accommodate fluctuations in demand,” mentioned Martinez-Moore. “Because of water being pumped at excessive temperature there are sometimes low ranges of suction strain obtainable, that means they’re typically fed by booster pumps to eradicate such points. Sealing on such pumps is generally carried out by mechanical seal or by packed gland, which may be most popular in purposes the place low NPSH situations could also be current, as mechanical seals can expertise accelerated put on in such situations.”

Mentioned Gaydon, “The boiler feed pumps would be the highest power-consuming pumps due to the excessive flowrates and differential pressures. In conventional coal-fired energy vegetation, these pumps may be as much as 60,000 horsepower, so assessing the operation of those pumps commonly to keep up optimum effectivity can lead to vital power financial savings.”

Know the Variables

Energy plant operators ought to take into account a number of variables in figuring out the proper pump to be used in an influence plant. “The precise utility issues are the primary place to begin [flow, head, NPSH, temperature, fluid, etc.] and perceive how variable they’re,” mentioned Gaydon. “Producers that provide pumps for the ability technology market can have designs focused to every utility.”

Gaydon instructed POWER, “Operationally, an important consideration is deciding on a pump that can function close to its finest effectivity level, or BEP, throughout regular operations, and can all the time function inside its allowable working area [AOR] for all situations. The AOR is a spread of flowrates the place the operational reliability of the pump is suitable.”

Some vegetation, akin to mixed warmth and energy, or these utilizing oil- or diesel-powered generators, will want gas switch pumps. Martinez-Moore instructed POWER, “Gasoline switch pumps, often known as gas forwarding or feed pumps, make sure the generators obtain the required volumes of gas, on the required strain for burning effectively. Fuels could also be pumped to a nozzle the place the gas could also be atomized, or on to a burner the place it ought to meet an outlined obligation level for the burner to provide the required warmth.”

Martinez-Moore mentioned, “A typical gas forwarding pump set consists of an obligation and standby pump to make sure redundant capability, transducers to document the working pump strain, and an built-in management panel with variable frequency drive to differ pump pace based on the circulation required.”

Shifting Tools

Pumping methods in energy vegetation transcend these used to maneuver liquids; in addition they might help transfer tools.

“Excessive-pressure hydraulic pumps that enable the positioning of heavy objects inside energy vegetation are essential to offer customers added flexibility and portability of what was historically a really onerous process,” mentioned David Lundquist, international product supervisor of the SPX FLOW Energy Workforce. “SPX FLOW, beneath the Energy Workforce model, manufactures pumps that characteristic The Energy Workforce movement management system. This method was not too long ago used for a 36-point hydropower rotor separation undertaking. The undertaking required a tilt characteristic to stage the rotor earlier than a 24-inch synchronous separation of the rotor for upkeep.”

Lundquist instructed POWER, “Prospects have been asking for extra options round a number of widespread challenges, together with choices to enhance portability and usefulness, tools that higher pairs energy with excessive circulation capability, and pumps which can be sturdy sufficient for essentially the most demanding purposes.” These purposes embrace compatibility with piping methods, which may embody water piping, together with service and cooling water; gas piping (for gasoline or gas oil); and chemical piping (for ammonia, acid, and many others.).

“When water is frequently reused from cooling towers inside a closed-loop system, the water can turn out to be contaminated as a consequence of it encountering particles akin to mud, in addition to [becoming] acidic because of the traits of the method and the supplies through which the water comes into contact,” mentioned Martinez-Moore. “In boiler feed purposes, because of the nature of the method with the water being repeatedly boiled, the extent of dissolved solids inside the water frequently will increase, which may result in scale accumulation and calcification forming inside the [piping] system, with dosing pumps used for the management of water high quality and environment friendly operation of the boiler.”

Martinez-Moore mentioned water discharged from a plant ought to meet sure requirements. “Dosing pumps are used to dose flocculant for the clarification of water, and [add] chemical substances to appropriate water pH to make sure it meets the required ranges for discharge consent,” he mentioned.

Martinez-Moore famous that piping methods at energy vegetation “can create the best situations for the expansion of Legionella micro organism, giving rise [to] the requirement for a dosing system for microbial management with biocides dosed to forestall Legionella,” referring to micro organism that causes Legionnaires’ illness. The U.S. Facilities for Illness Management and Prevention has mentioned controlling Legionella micro organism is a vital consideration, and a serious motive pipe methods at energy vegetation have to be “correctly disinfected and maintained.”

—Darrell Proctor is a senior affiliate editor for POWER (@POWERmagazine).