Three main chemical processing corporations introduced the startup of an illustration plant to point out the viability of large-scale electrically heated steam cracking furnaces.

BASF, SABIC, and Linde on April 17 mentioned the power, at BASF’s Verbund web site in Ludwigshafen, Germany, will start working after three years of growth, engineering, and building work. The three teams in March 2021 signed an settlement to collectively develop and exhibit options for electrically heated steam cracking furnaces.

The businesses in a information launch wrote, “Steam crackers play a central position within the manufacturing of fundamental chemical compounds and require a big quantity of vitality to interrupt down hydrocarbons into olefins and aromatics. Sometimes, the response is performed in furnaces at temperatures of about 850 levels Celsius. Thus far, these temperatures have been reached through the use of standard fuels. The demonstration plant goals to point out that steady olefin manufacturing is feasible utilizing electrical energy as a warmth supply. By utilizing electrical energy from renewable sources, the brand new know-how has the potential to cut back CO2 emissions of some of the energy-intensive manufacturing processes within the chemical trade by at the least 90% in comparison with applied sciences generally used immediately.”

Need to be taught extra about how electrification is remodeling the facility technology and industrial sectors? Register now and be a part of POWER, together with specialists on electrification, on the P3 Electrified Summit in San Diego, California, Sept. 17-18, 2024.

These teams’ announcement got here at some point after Lummus Know-how, a worldwide supplier of course of applied sciences and value-driven vitality options, and Braskem, the most important bio-based polymer producer on the earth, on April 16 mentioned they are going to work on joint research associated to the economic demonstration of Lummus’ SRT-e electrical cracking heater. The know-how might be used to decarbonize certainly one of Braskem’s websites in Brazil.

The businesses mentioned the mission “will set the idea for the eventual negotiation between Lummus and Braskem of a definitive settlement that can, amongst different issues, set up the overall pointers by which such implementation will happen.”

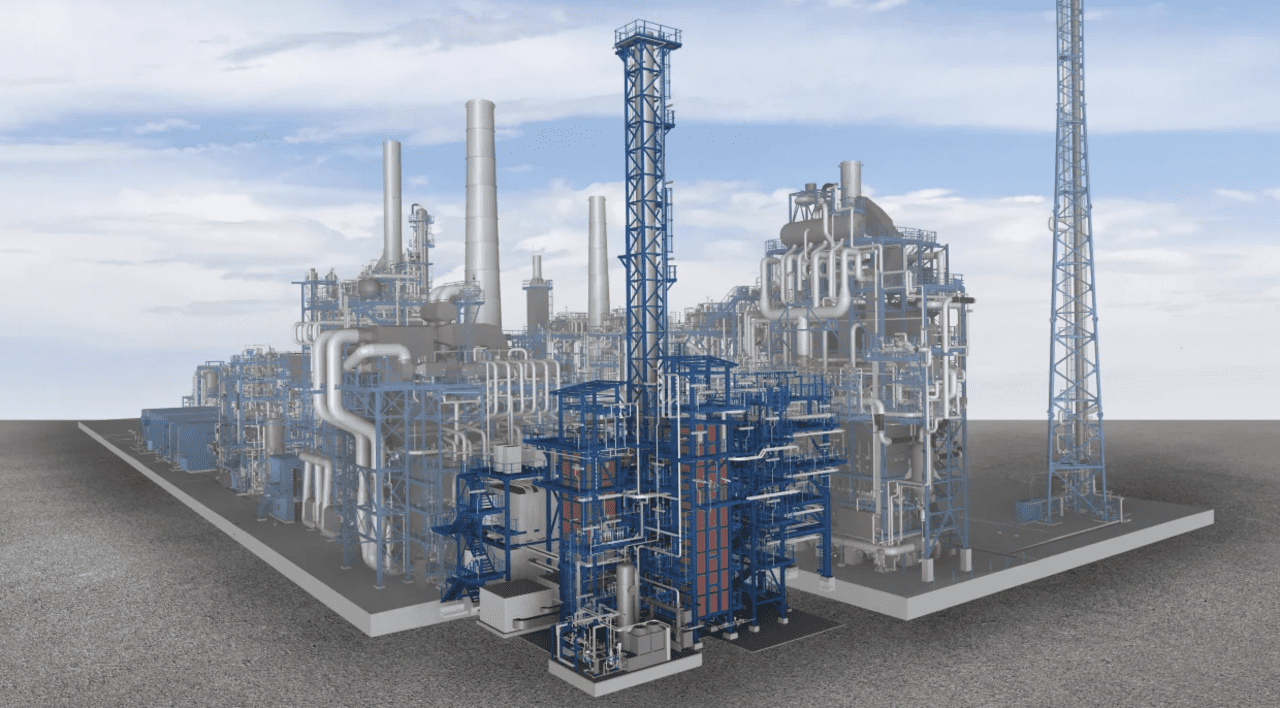

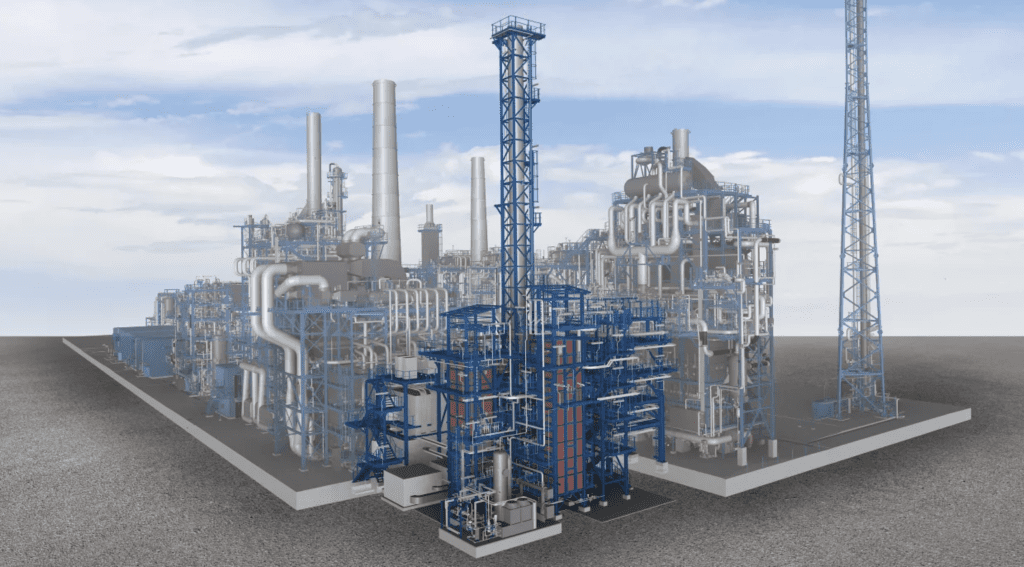

Ludwigshafen Demonstration Plant

The demonstration plant in Germany will produce olefins, together with ethylene and propylene, and likewise may make increased olefins from saturated hydrocarbon feedstock. The ability is totally built-in into the prevailing steam crackers on the Ludwigshafen web site, which serves as BASF’s headquarters.

The teams mentioned the demonstration plant will collect “information and experiences about materials conduct and processes underneath industrial working situations for the ultimate growth of this progressive know-how to industrial market maturity.” The plant has two separate demonstration furnaces, and every will check a special heating idea. Direct heating applies an electrical present to the cracking coils in a single furnace. The second furnace options oblique heating, utilizing radiative warmth of heating components positioned across the coils.

The businesses mentioned two furnaces collectively will be capable of course of about 4 tons of hydrocarbon feedstock hourly, and devour 6 MW of vitality from renewable sources.

The mission’s growth was supported by a €14.8 million ($15.8 million) grant from the German Federal Ministry for Financial Affairs and Local weather Motion underneath its “Decarbonization in Trade” funding program. This system is supporting energy-intensive industries in Germany which are working to realize carbon neutrality.

“With the event of electrically operated steam cracking furnaces, we’re getting our palms on a key know-how that can assist to considerably scale back greenhouse fuel emissions within the chemical trade,” mentioned Dr. Martin Brudermüller, chairman of the board of govt administrators of BASF SE. “It fills me with delight and pleasure that we’ve got achieved this success along with our companions SABIC and Linde. The demonstration plant right here in Ludwigshafen will present us with precious expertise on the ultimate step in the direction of the economic utility of this know-how.”

SABIC CEO Abdulrahman Al-Fageeh mentioned, “The e-furnace’s know-how holds enormous potential for the sustainability of the worldwide petrochemical trade. It could possibly exhibit the position that renewable electrical energy can play in increased effectivity and low-emission chemical processing. By way of shut collaboration, teamwork, mental property growth, and advancing one of the best technical options holistically, the groups at SABIC, BASF and Linde have introduced this mission to this key stage. We’re proud to be right here collectively immediately to have a good time the facility of collective motion on our journey towards a round carbon financial system.” SABIC is headquartered in Saudi Arabia.

The Ludwigshafen demonstration plant might be operated by BASF. Linde, primarily based in Dublin, Eire, was accountable for the engineering, procurement, and building of the plant. Linde will commercialize the developed applied sciences on the facility underneath the brand new trademark STARBRIDGE, which is designed to assist the petrochemical trade decarbonize by changing conventional-fired applied sciences which have been supported by fossil fuels.

“It’s our frequent objective to exhibit that it’s attainable to affect the petrochemical trade and to function a steam cracker with sustainably generated electrical energy,” mentioned Jürgen Nowicki, CEO of Linde Engineering. “This excellent joint mission is a big proof of how collectively we will develop groundbreaking applied sciences that can advance us on the journey in the direction of net-zero CO2 emissions and climate-neutral trade. The STARBRIDGE know-how brings the imaginative and prescient of an emission-free petrochemical trade a step nearer.”

Decarbonize Brazilian Ethylene Facility

The mission on the plant in Brazil, utilizing the SRT-e electrical cracking heater, “leverages Lummus’ confirmed Quick Residence Time (SRT) know-how modified to function utilizing electrical energy and incorporates a modular unit-cell design that may be replicated for vegetation to accommodate any industrial capability,” in response to a information launch. Lummus and Braskem officers mentioned the know-how “makes use of all commercially demonstrated parts, plus an optimum warmth flux profile resulting in an extended radiant coil life and longer run size. As well as, decoking may be carried out on a unit-cell foundation so sustaining a spare heater is just not required.”

“The choice of Lummus’ SRT-e electrical cracking heater as a method to decarbonize Braskem’s ethylene vegetation are based on a shared dedication to develop and implement worthwhile sustainable applied sciences and options,” mentioned Jose de Barros, vice chairman and managing director of ethylene for Houston, Texas-based Lummus Know-how. “We sit up for demonstrating our breakthrough electrification know-how that drastically reduces greenhouse fuel emissions.”

Braskem, headquartered in São Paulo, Brazil, has a objective to cut back its greenhouse fuel emissions by 15% p.c by 2030. The corporate desires to be carbon-neutral by 2050. Braskem operates 40 industrial models in Brazil, the U.S., Mexico, and Germany, and exports its merchandise to greater than 70 international locations.

“Our ambition is to significantly scale back CO2 emissions and enhance the sustainability of our merchandise by means of innovation, in-house developments, and necessary partnerships. Lummus’ SRT-e know-how will assist Braskem obtain its objective of carbon neutrality by 2050, which can assist enhance vitality effectivity at our crackers,” mentioned Antonio Queiroz, Braskem VP for Innovation, Know-how and Sustainable Improvement. “Increasing using renewable electrical energy and renewable supplies will allow Braskem to cut back its carbon footprint within the manufacturing of ethylene, propylene and different chemical compounds.”

—Darrell Proctor is a senior affiliate editor for POWER (@POWERmagazine).